1. Greenhouse gas emissions and climate change

Topic lead: President Systems Division

Our target for 2027: We want to reduce our greenhouse gas emission intensity for Scope 1 and 2 by 50%.

Tackling climate change is one of the most pressing global challenges.The potential consequences of climate change are grave, in some cases irreversible, and affect individuals, organizations, and countries alike. The Paris Agreement of 2015 is a legally binding international treaty between states on climate change. It recognizes the need to limit global warming to below 2 °C above pre-industrial levels, preferably as low as 1,5 °C.

We recognize our responsibility and the potential to reduce our greenhouse gas emissions across the enire value chain. Our activities and technology make an increasing contribution to combating climate change and to supporting Sustainable Development Goal 13: Climate action.

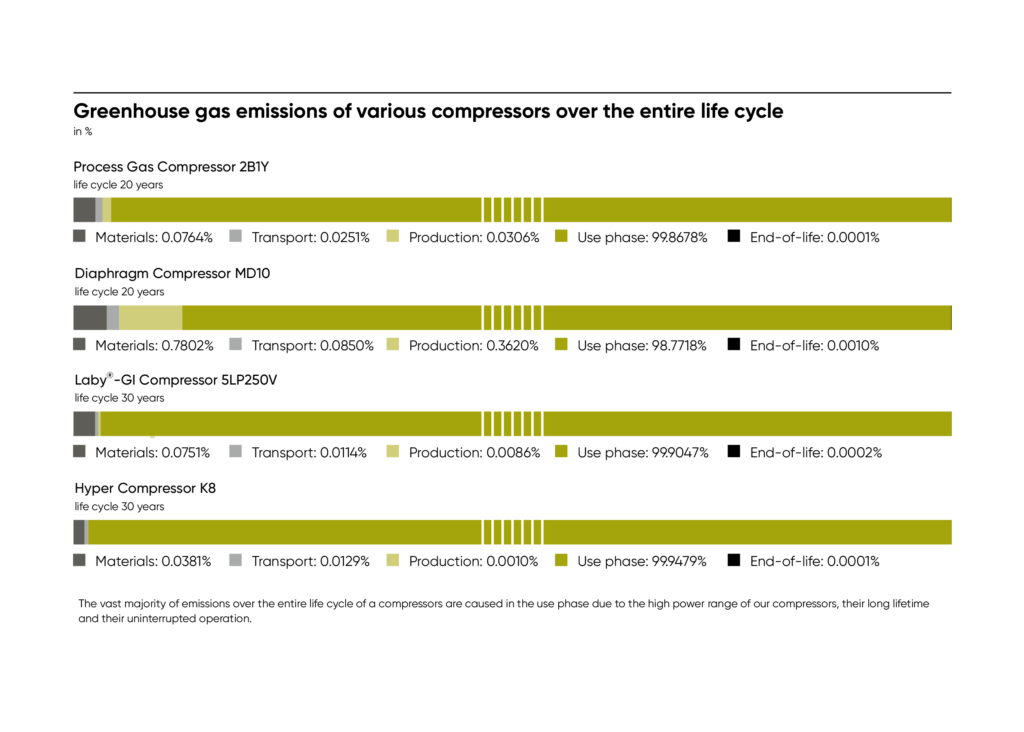

The majority of the emissions associated with our business activities arises in the use phase of our compressors due to their long lifetime of 30 to 50 years. Other emissions occur in our operating facilities, where we have the most direct influence, and in logistics and the materials used.

Our approach

We endeavor to reduce our carbon footprint and optimize emissions during the use phase of the compressors. We focus on three key areas:

- Reduction of the company’s carbon footprint

- Optimization of the impact of our inbound and outbound logistics

- Improvement of the carbon footprint of compressors

Reduction of greenhouse gas emissions during the use phase of our compressor systems is an integral part of our product and innovation management. With our services, we help our customers reduce emissions from installed compressors.

Our climate policy is the basis for all our activities related to climate change and part of our wider environmental policy. Our environmental management system, certified in accordance with ISO 14001, is a key instrument in reducing our environmental footprint. Each subsidiary takes responsibility for reducing its own greenhouse gas emissions according to the global targets.

We have embedded our target of reducing our greenhouse gas emission intensity by 50% as part of top management’s long-term incentives.