4. Environmental impacts of application purpose

TOPIC LEAD: VICE PRESIDENT SALES SYSTEMS DIVISION

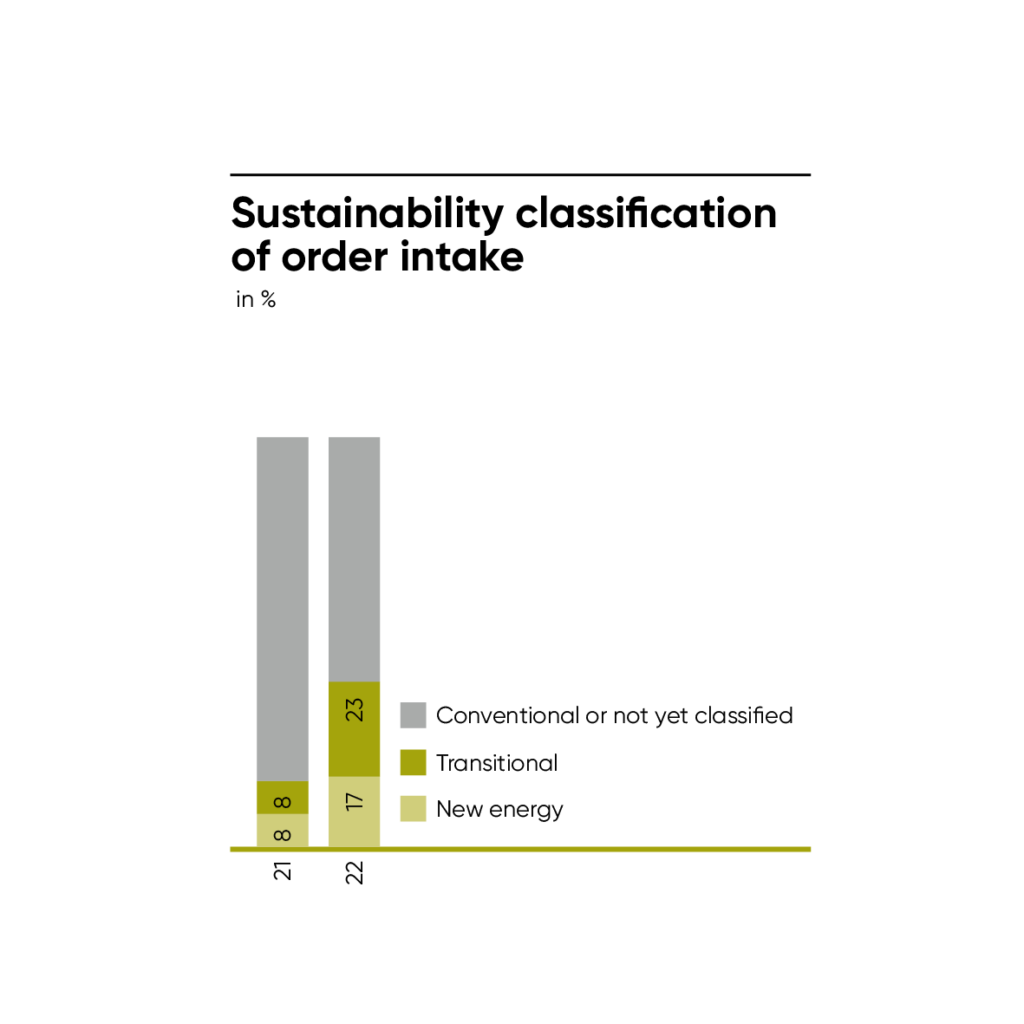

Our target for 2027: We want to reach an order intake of 40% in applications supporting the energy transition.

Our core competence is mastering gas compression technologies for a wide range of gases and applications. Gas plays a crucial role in process industry and energy supply, with applications ranging from conventionial energy supply to industrial gases to renewable energy systems. A significant part of the indirect environmental impact of our business activities is linked to the application purpose.

We have the potential to conbribute to three of our strategic Sustainable Development Goals (SDG 7: Affordable and clean energy, SDG 12: Responsible consumption and production, and SDG 13: Climate action). The main impacts of this topic are related to the use phase of our products and services.

Our approach

We are committed to the long-term alignment to analyze our business activities with a sustainable economic system. We identified four positive impact areas:

- Climate change mitigation

- Energy transition

- Circular economy

- Environmental pollution prevention

We have developed a sustainability screening approach to analyze our business activities from an environmental impact perspective. This classification system makes use of international standards such as the EU taxonomy for sustainable activities or South Korea’s K-Taxonomy, without claiming to fulfil all their technical requirements. The main purpose of our screening system is to serve as a compass for the development of our business activities towards a sustainable energy future.

We are expanding the range of application for our customers and supporting the transition to a sustainable economy through our continuous innovation in compressor systems, materials, components, and services. Our approach is mainly driven by our innovation, product management and sales processes. We invest in R& D for key applications of the energy transition. The current focus lies on:

- Solar energy value chain, where our compressors are key equipment for the production of a thin ethylene-vinyl acetate (EVA) film on top of a solar panel and for the polysilicon production of the core.

- Liquefied Natural Gas (LNG) as a short- and medium-term bridge energy for replacing coal, ensuring energy security during the transition or as a fuel for marine applications, replacing carbon-intensive heavy fuel oil until zero-emission solutions are available.

- Hydrogen as an important component of a sustainable energy future, in which our compressors play a key role in meeting the specific technical challenges of these new applications. The technological advantages of reciprocating compressors for this application are unrivaled efficiency and long service lives.