11. Oktober 2016 | Success Story, Nordamerika, Prozessgas-Kompressor, Petro-/Chemische Industrie

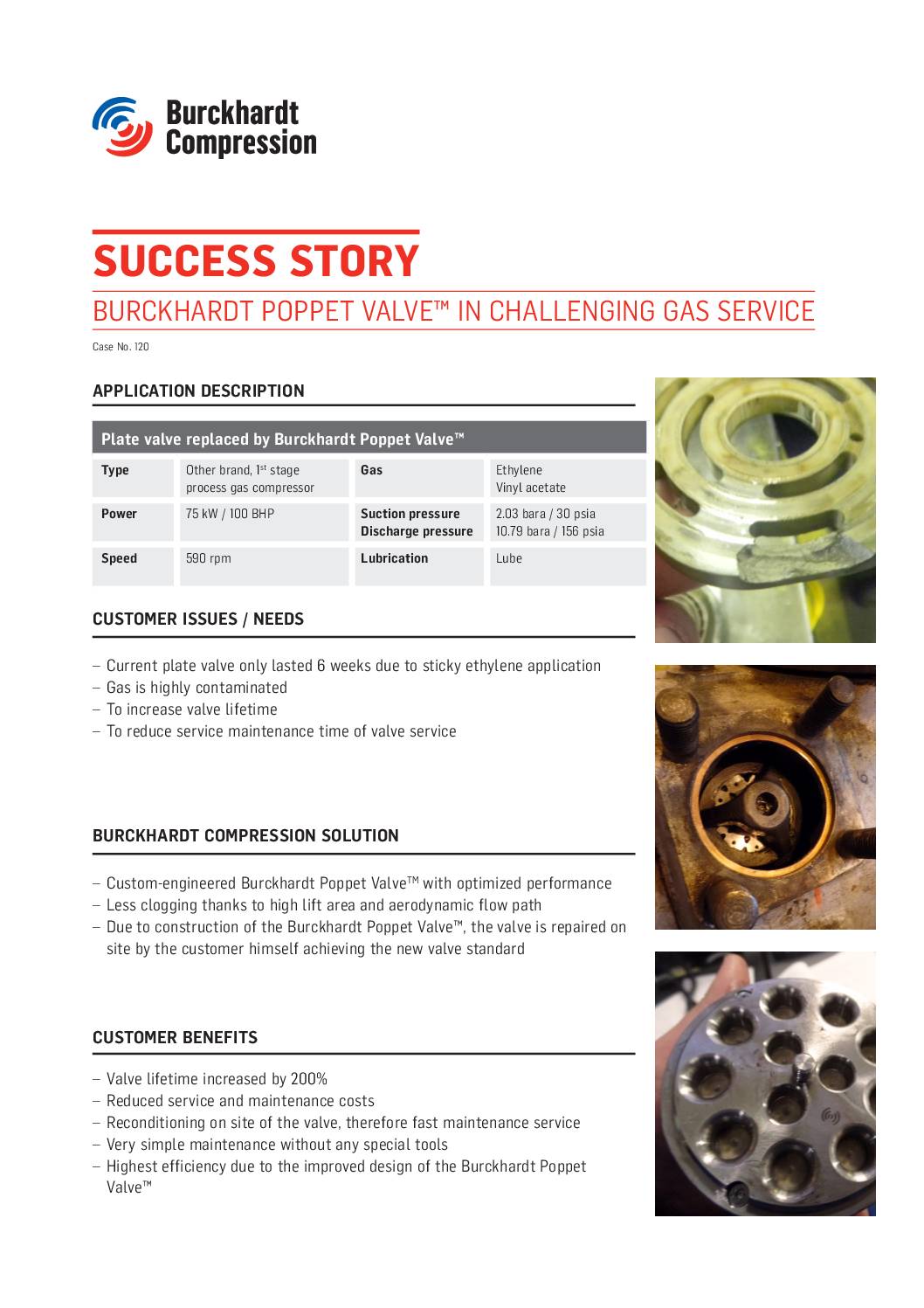

Burckhardt Poppet Valve™ in Challenging Gas Service

The valves of a non-Burckhardt compressor only lasted for 6 weeks in a challenging application. Burckhardt Compression analyzed the problem could increase the valve lifetime by 200% by installing poppet valves.

Customer Challenges:

- Current plate valve only lasted 6 weeks due to sticky ethylene application

- Gas is highly contaminated

- To increase valve lifetime

- To reduce service maintenance time of valve service

Application Description:

| Type | Dresser Rand Clark

CMA-2, 1st Stage |

Gas | Ethylene

Vinyl acetate |

| Power | 75 kW / 100 BHP | Suction pressure

Discharge pressure |

2.03 bara / 30 psia

10.79 bara / 159 psia |

| Speed | 590 rpm | Lubrication | Lube |

Burckhardt Comression Solution:

- Custom-engineered Burckhardt Poppet ValveTM with optimized performance

- Less clogging thanks to high lift area and aerodynamic flow path

- Due to construction of the Burckhardt Poppet Valve™, the valve is repaired on

site by the customer himself achieving the new valve standard