16. Mai 2011 | Asien, Petro-/Chemische Industrie, Success Story, Hyper-Kompressor

Compressor Revamp – Successful Increase of Mass Flow

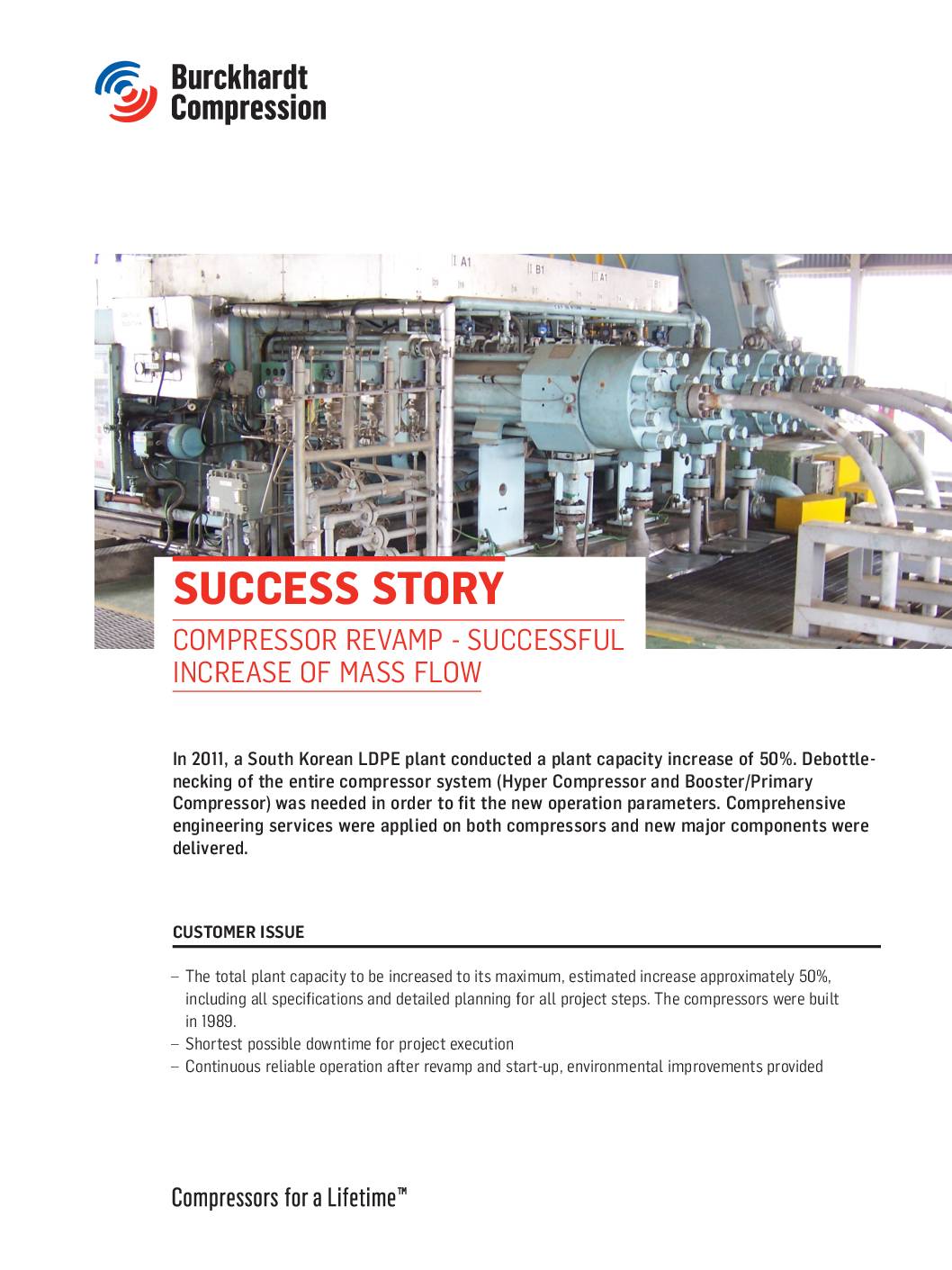

In 2011, a South Korean LDPE plant conducted a plant capacity increase of 50%. Debottlenecking of the entire compressor system (Hyper Compressor and Booster/Primary Compressor) was needed in order to fit the new operation parameters. Comprehensive engineering services were applied on both compressors and new major components were delivered.

„This project was finalized seven years ago. Today, I can confirm that both compressors are still running to our full satisfaction. Burckhardt Compression’s engineering competence and their pro-active approach fully met our expectations. In 2016, we placed a revamp follow-up order for our K10 Hyper Compressor due to another plant capacity increase of 20%.“

Yungwoo Lee, LDPE Plant Manager

Customer Challenges:

- The total plant capacity to be increased to its maximum, estimated increase approximately 50%, including all specifications and detailed planning for all project steps. The compressors were built in 1989.

- Shortest possible downtime for project execution

- Continuous reliable operation after revamp and start-up, environmental improvements provided

Application Description:

| Type |

Burckhardt Compression Hyper Compressor: F8 Booster/Primary: 6B5A-1.57 |

Gas |

Ethylene |

| Power |

12’700 hp / 9’500 kW |

Suction pressure

Discharge pressure |

250 barg/3’620 psia

2’750 barg/40’000 psia |

| Speed |

200 rpm |

Lubrication |

Forced lubrication to cylinder |

Burckhardt Compression Solution:

- Close cooperation with compressor user and process design.

- Debottlenecking of the entire compressor system to fit the new operation parameters to increase the mass flow from 46t/h up to 63t/h by enlargement of plunger diameter, cylinder and replace the main drive.

- Comprehensive engineering services like performance calculations, torsion analysis, pulsation study, vibration study were applied.

- Modernization of defined components like N2 buffered low pressure packing and auxiliaries.

- Know-how and experience provided from the market leader in LDPE compressor manufacturing.

Customer Benefits:

- Successful increase of the mass flow from 46t/h up to 63t/h

Increased reliability and lower life cycle costs with the new solution - Effective environmental improvements in process technology

- Delivery to full customer satisfaction and warranty on our solutions