28. Februar 2020 | Asien, Success Story, Raffinerie, Prozessgas-Kompressor

Compressor Revamp to guarantee its proper Functioning

The Indian Oil Corp. Ltd. in Haldia, India, had problems with two of its compressors. Without any major overhauls, the two 27-year-old compressors – one operational, the other in standby – were prone to malfunction because of its damaged piston rings, valve plates and springs. Burckhardt Compression revamped the compressor – which included modifying the existing piston and piston rings – to bring it back to proper functionality.

„We are very satisfied with the work of Burckhardt Compression. Since the compressor was revamped, its performance has been excellent. Based on the available information and the his own observations during disassembly of the compressor, the field service engineer suggested various modifications to overcome and resolve the existing issues.

Helpful and thoughtful!”Tanmoy Sarkar, Maintenance Manager, Haldia Refinery

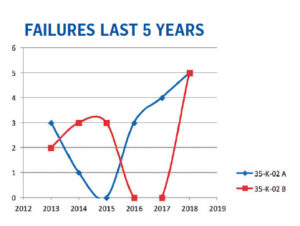

Customer Challenges:

- Two 27-year old compressors in operation

- Frequent failure of piston rings, valve plates and springs

- No original OEM manual or other data about clearances / tolerances / limits available

Application Description:

| Type | Other brand compressor 164 ME 125ch |

Gas | Hydrogen |

| Power | 37 kW | Suction pressure

Discharge pressure |

65 kg/cm2_a

75 kg/cm2_a |

| Speed | 410 rpm | Lubrication | Lube |

Burckhardt Compression Solution:

- On-site analysis based on history, available data and observations

- Detailed study and recommendations

- Modification of existing piston, piston rings and packings

- Reverse engineering and delivery of cylinder liner

- Refurbishment of the crankshaft, Tungsten Carbide coating of the piston rod and

refurbishment of the piston - Rectification of the compressor foundation and total installation

Customer Benefits:

- Zero machine downtime: running without any issues and or frequent maintenance needs

- Increase of mean time between failures (MTBF)

- Increase of final discharge flow by 15% at the same operating conditions and

gas purity - Reduced process gas leakage from the piston rod packing

- Reduction in the vibration level with regards to the standby compressor

- Customer Service available at all times

- Full warranty on all new parts manufactured by Burckhardt Compression

Watch the story: