7. November 2017 | Mittlerer Osten & Afrika, Petro-/Chemische Industrie, Success Story, Hyper-Kompressor

High Pressure Packings – Still Running after over 26’000 Hours

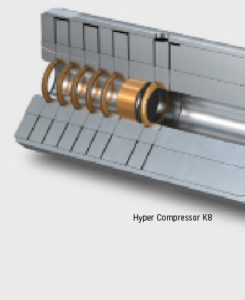

Since 2012, Sipchem, Saudi International Polymer Company (IPC), has been operating a Burckhardt Compression K8 Hyper Compressor at their LDPE-EVA plant in the Jubail area. The 2nd stage packings are still in service after more than 26'000 operating hours and the central valves after more than 19'000 operating hours. The compressor is running at 3'100 bara discharge pressure and under extremely challenging conditions.

Customer Challenges:

- Longer operating hours for the Hyper Compressor under harsh conditions (LDPE/EVA plant, 3’100 bara)

- Minimum plant shutdowns

- Longer lifetime of the high pressure key equipment

Application Description:

| Type | Burckhardt Compression Hyper Compressor K8 | Gas | Ethylene |

| Power | 15’570 kW / 20’800 hp | Suction pressure

Discharge pressure |

286 bara / 4’150 psia

3’100 bara / 45’000 psia |

| Speed | 200 rpm | Lubrication | Customized lubrication system |

Burckhardt Compression Solution:

- Heterogeneous Redura® High Pressure Sealing System design based on decades of experience for highest sealing efficiency

- Persisto® material for sealing elements: specific material selection with enormous mechanical and chemical resistance

- Burckhardt HyproPack™ cartridge system for fast exchange and service

- High quality central valves: customized multi-poppet design for optimized efficiency, optimized flow and best performance for long lifetime

Customer Benefits:

- Extended life of key components lasting more than twice as the market standards

- Longer meantime between overhaul

- Outstanding system availability

- Significant reduction of maintenance and operating costs

- Know-how and experience provided from the market leader in LDPE compressor design

- Tailor-made technical support according to customer requirements