20. Juli 2022 | Industrie Gas, Non-Burckhardt, Success Story, Europa

Re-engineering of other brand compressor cylinder within tight time frame

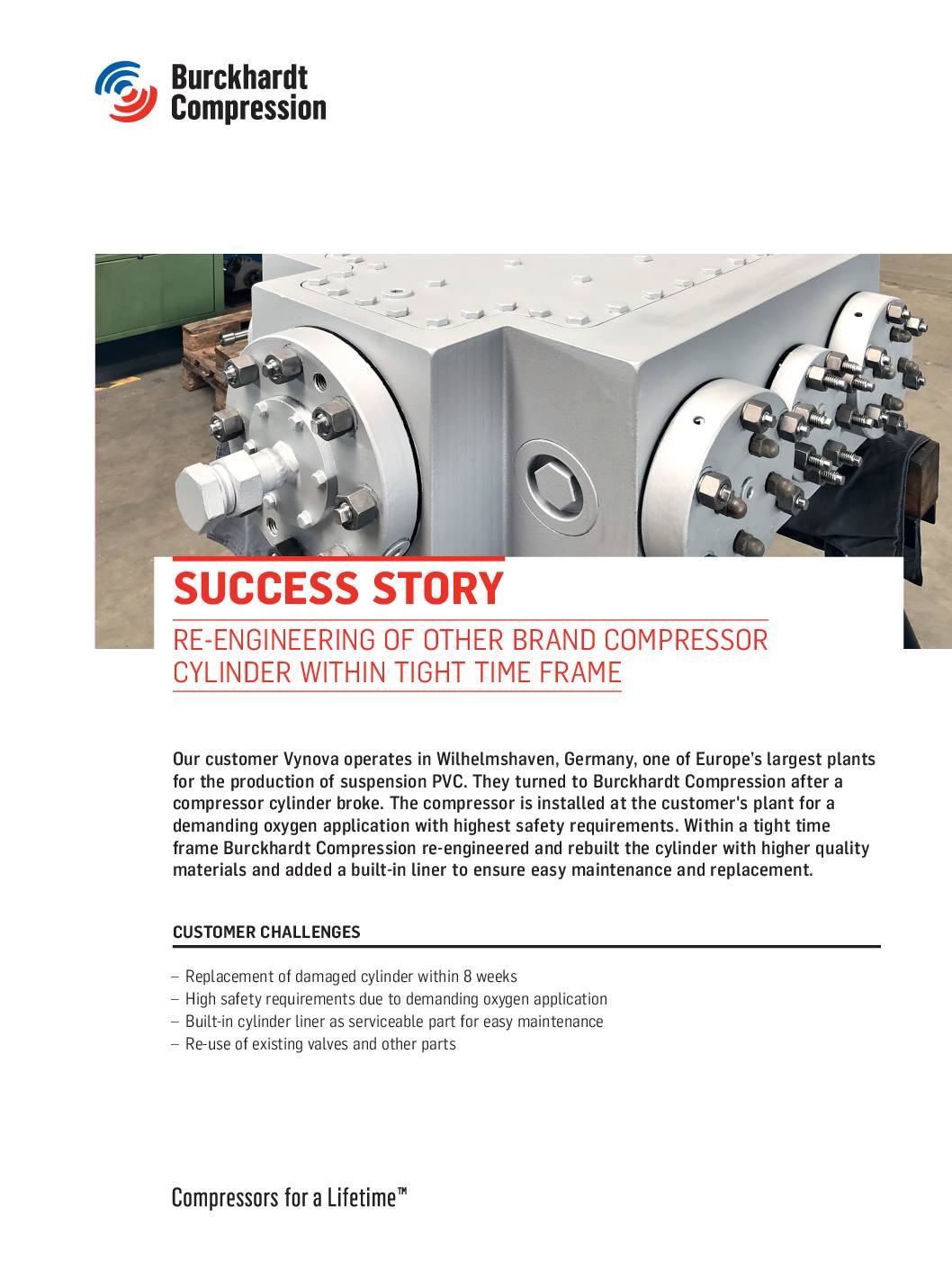

Our customer Vynova operates in Wilhelmshaven, Germany, one of Europe’s largest plants for the production of suspension PVC. They turned to Burckhardt Compression after a compressor cylinder broke.

The compressor is installed at the customer’s plant for a demanding oxygen application with highest safety requirements. Within a tight time frame Burckhardt Compression re-engineered and rebuilt the cylinder with higher quality materials and added a built-in liner to ensure easy maintenance and replacement.

Customer Challenges:

- Replacement of damaged cylinder within 8 weeks

- High safety requirements due to demanding oxygen application

- Built-in cylinder liner as serviceable part for easy maintenance

- Re-use of existing valves and other parts

| Cylinder repair of third-party oxygen compressor | |||

| Type | Other brand compressor Type 1TES30 |

Gas | O2 |

| Power | 37 kW / 49 hp | Suction pressure

Discharge pressure |

10 barg / 145 psia

23 barg / 333 psia |

| Speed | 660 rpm | ||

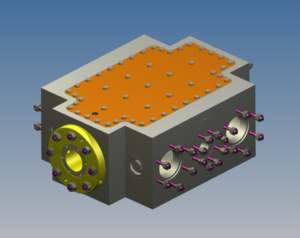

Burckhardt Compression Solution:

- Reverse engineering of existing cylinder carried out by local team

- Upgrade cylinder design and material in order to add a built-in cylinder liner

- Project management

- On-site assembly with support from our local Field Service Representative

Customer Benefits:

- Zero safety incidents due to highest safety standards

- Increased plant reliability thanks to higher quality material

- Replaceable cylinder liner for easier maintainability

- Existing compressor valves and parts can still be used after cylinder replacement