July 24, 2010 | Success Story, Petrochemical/Chemical Industry, Europe, Hyper Compressor

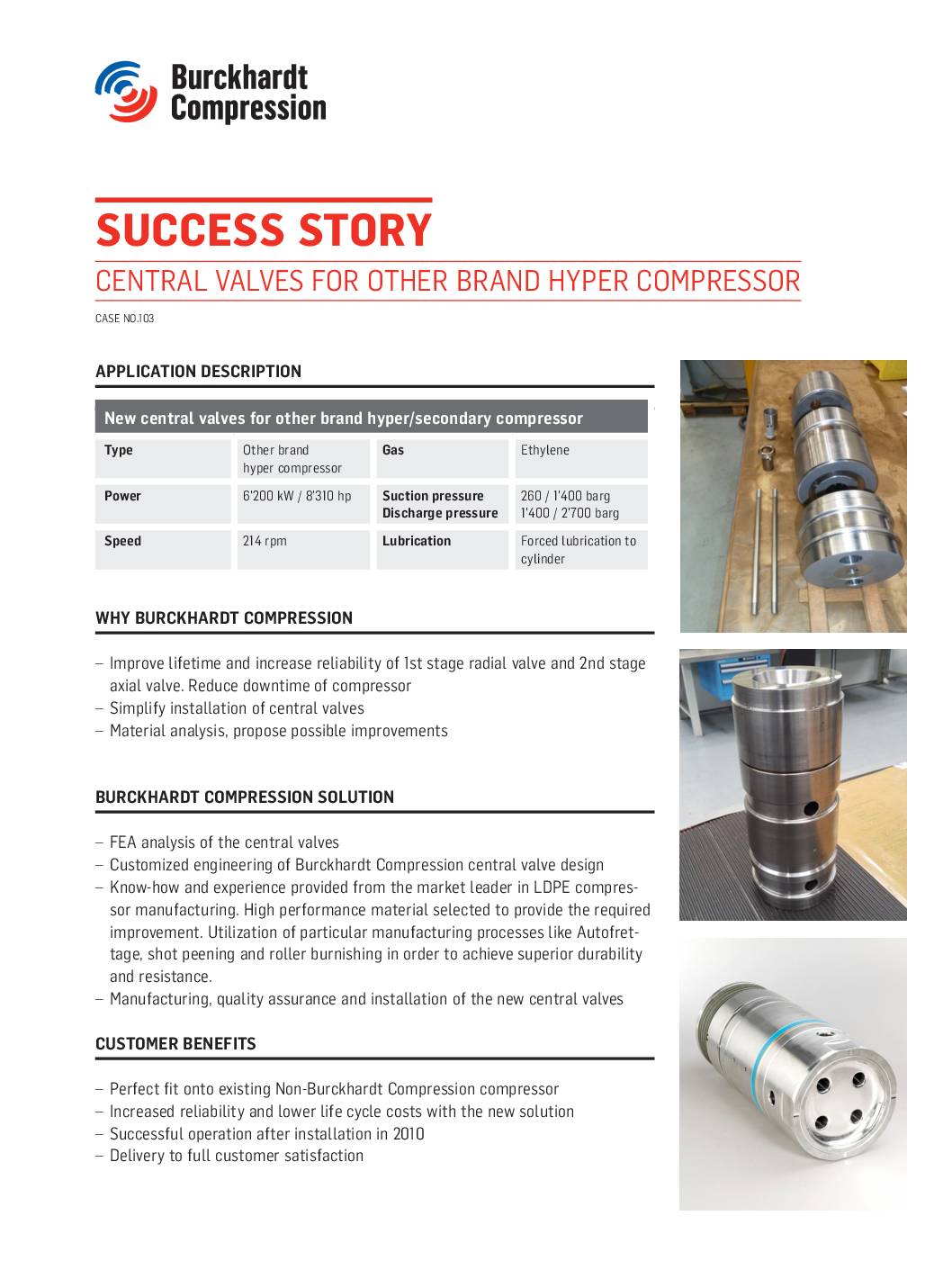

New Hyper Compressor Central Valves

A customer turned to Burckhardt Compression for help with his non-Burckhardt hyper compressor. The compressor valves needed a complete overhaul to optimize operation and improve its reliability. With the solution even the life-cycle cost could be reduced.

Customer Challenges:

- Improve lifetime and increase reliability of 1st stage radial valve and 2nd stage axial valve.

- Reduce downtime of compressor

- Simplify installation of central valves

- Material analysis, propose possible improvements

Application Description:

| Type | Other brand hyper compressor | Gas | Ethylene |

| Power | 6’200 kW / 8’310 hp | Suction pressure

Discharge pressure |

260 / 1400 barg

1’400 / 2’700 barg |

| Speed | 214 rpm | Lubrication | Forced lubrication to cylinder |

Burckhardt Compression Solution:

- FEA analysis of the central valves

- Customized engineering of Burckhardt Compression central valve design

- Know-how and experience provided from the market leader in LDPE compressor manufacturing. High performance material selected to provide the required improvement. Utilization of particular manufacturing processes like Autofrettage, shot peening and roller burnishing in order to achieve superior durability and resistance.

- Manufacturing, quality assurance and installation of the new central valves