23. Juli 2018 | News

Relocation & Modernization of 35-year-old Oxygen Laby® Compressor – Fit to New Operating Condition

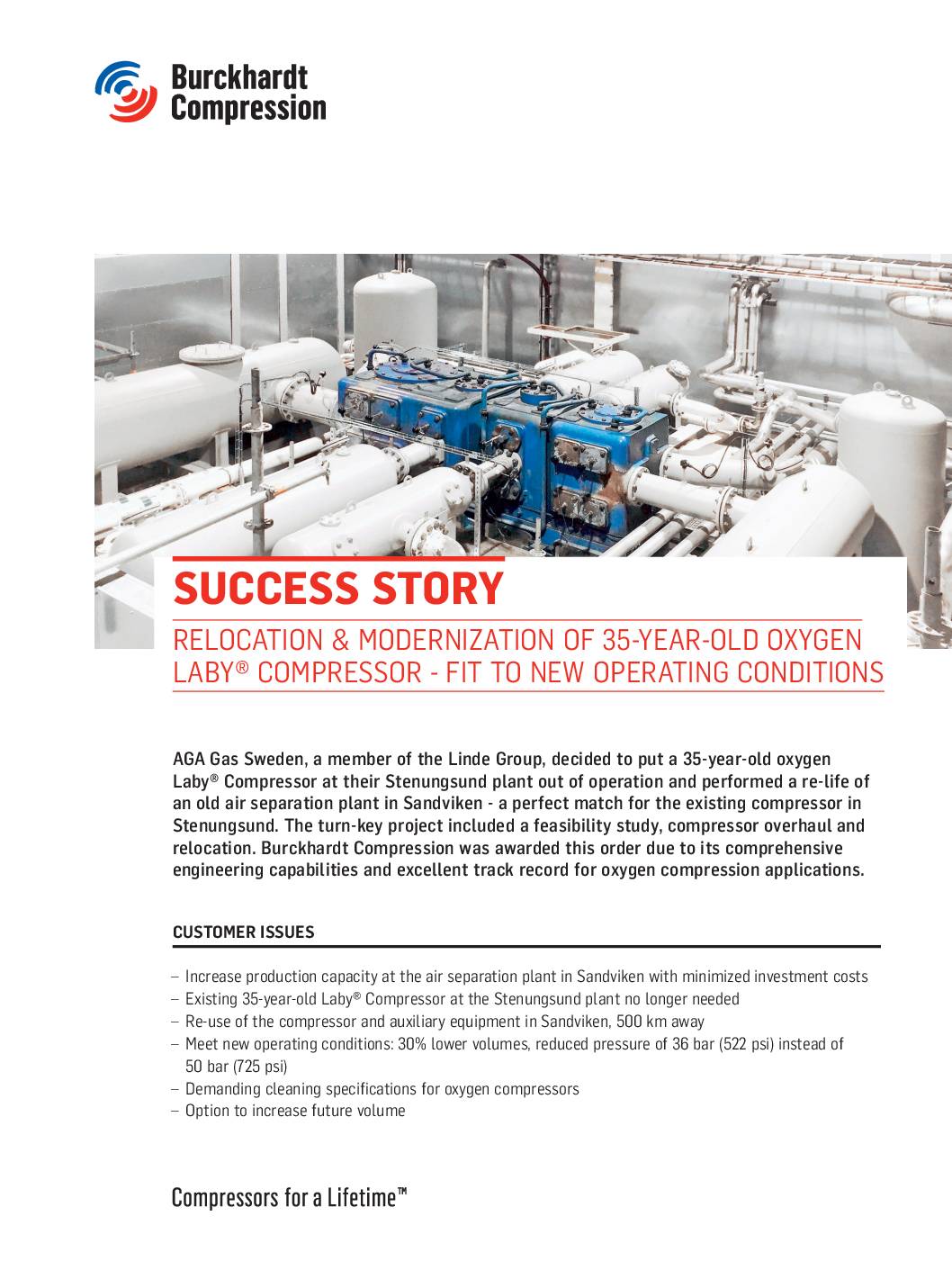

AGA Gas Sweden, a member of the Linde Group, decided to put a 35-year-old oxygen Laby® Compressor at their Stenungsund plant out of operation and performed a re-life of an old air separation plant in Sandviken - a perfect match for the existing compressor in Stenungsund. The turn-key project included a feasibility study, compressor overhaul and relocation. Burckhardt Compression was awarded this order due to its comprehensive engineering capabilities and excellent track record for oxygen compression applications.

„I am very satisfied with the good and reliable services provided by Burckhardt Compression’s reciprocating field service engineers. Frictionless collaboration and their comprehensive extensive know-how made everyone happy and I am looking forward to working with them again for future maintenance service.“

Mats Mjörnling

Plant Manager, AGA Gas, Sweden

Customer Issues:

- Increase production capacity at the air separation plant in Sandviken with minimized investment costs

- Existing 35-year-old Laby® Compressor at the Stenungsund plant no longer needed

- Re-use of the compressor and auxiliary equipment in Sandviken, 500 km away

- Meet new operating conditions: 30% lower volumes, reduced pressure of 36 bar (522 psi) instead of

50 bar (725 psi) - Demanding cleaning specifications for oxygen compressors

- Option to increase future volume

Application Description:

| Type | Laby® Compressor 4D300 |

Gas | Oxygen |

| Power | 800 kW / 1’072 hp | Suction pressure

Discharge pressure |

1.2 bara / 174 psia

35 bara / 507 psia |

| Speed | 420 rpm | Lubrication | Oil-free |

Burckhardt Compression Solution:

- Feasibility study, including thermodynamic analysis

- Overhaul of crankgear and upgrade of compressor parts to the latest technology

- Dismantling and labelling of all parts and preparing for shipment

- Compressor relocation including all auxiliaries, such as cooling system, dampeners, oil system, supports and piping system

- Special parts cleaning according to safety specifications for oxygen compression

- Black light controlling of all parts to make sure they are spotlessly clean and completely oil-free

- Alignment with a smaller motor

- Re-installation and commissioning at the new plant 500 km away

Customer Benefits:

- 60% lower investment costs

- Half the delivery time of a new compressor solution

- 4 MW/hour energy savings

- Compressor complies with the latest technology and safety standards

- Laby® Compressor modified to meet new operating conditions with an option to increase future volumes