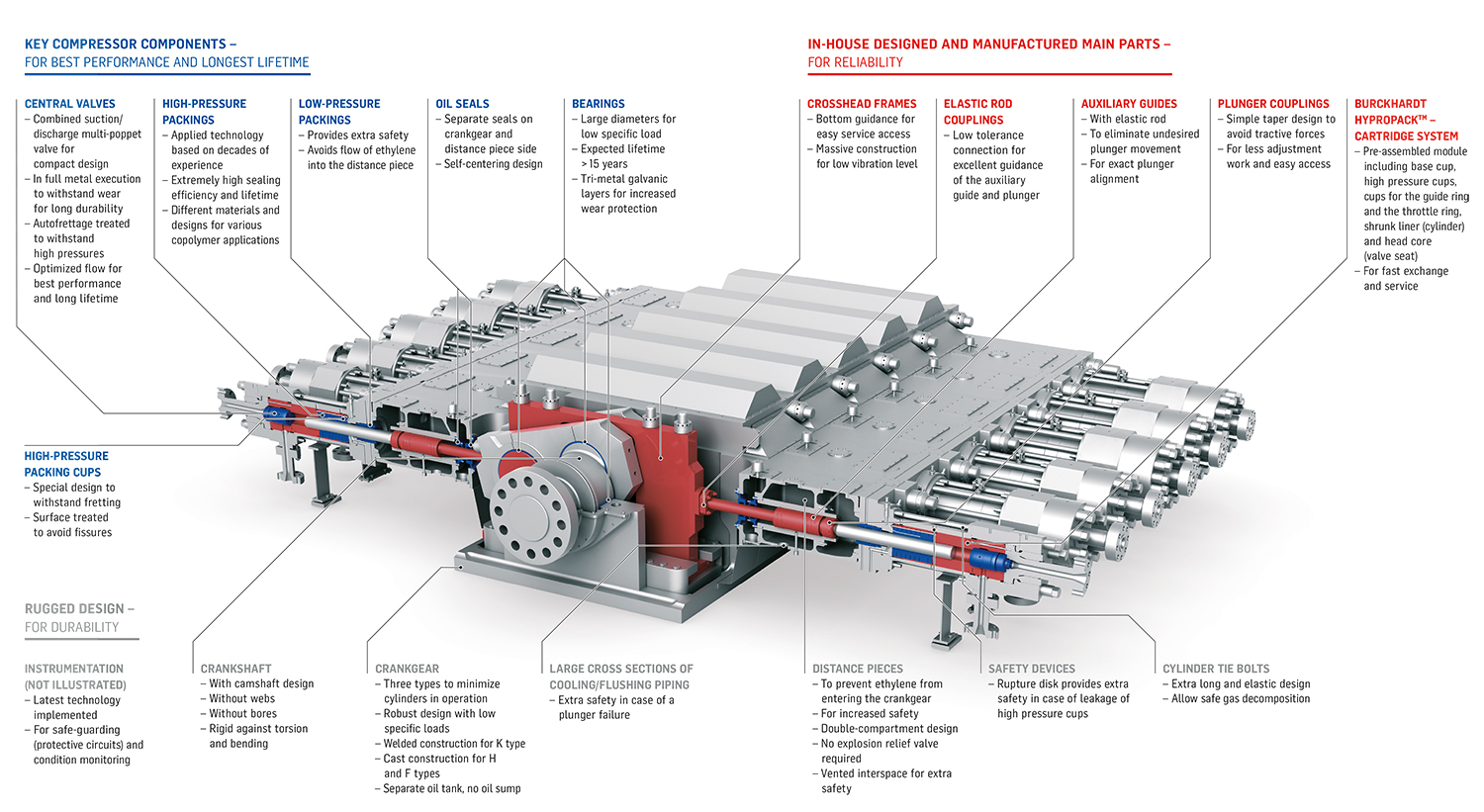

Design Features

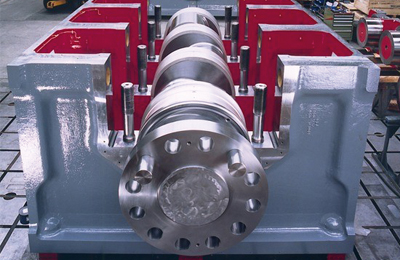

Optimized Crankcase and Crankshaft

- Robust crankcase design for reliable performance

- No oil sump in the crankcase

- Large bearing diameters for low specific loading

- Crankshaft without webs and inner holes

- Rigid connecting rod for optimum pressure distribution

- Crankcase lubrication system

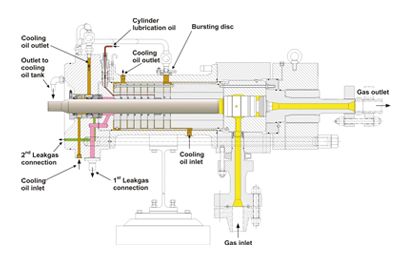

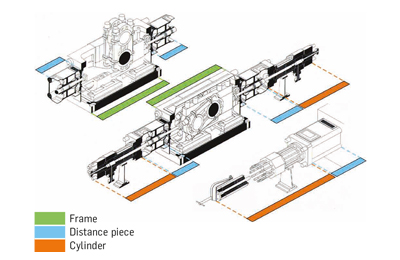

Cylinder Layouts for Highest Demands

- Implemented features for easy and fast maintenance

- Bursting disc on cylinder body with leak gas emergency piping

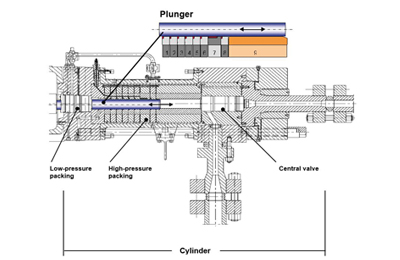

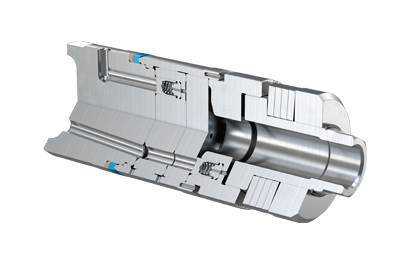

High-Pressure Packing

- Special shape of high-pressure inner packing cups

- Burckhardt HyproPack™ – fast cylinder exchange and service

- Burckhardt HyproPack™ – packing and ring design for increased safety

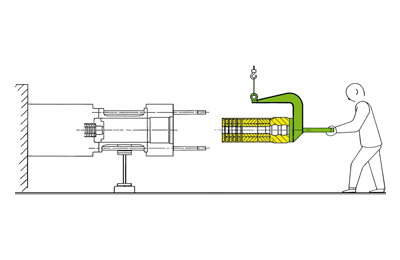

Additional Distance Piece for Higher Safety

The additional distance piece prevents ethylene gas from entering the crankcase, during normal operation as well as in case of an accident. In case of a complete plunger failure the inner cylinder diameter works as a leak gas piping and up to five times of the compressor mass flow occurs in the distance piece. The cooling oil return piping is oversized to allow gas pressure release during an incident. Therefore, an explosion relief valve is not required for our secondary crankcase.

High-Performance Valves

Valves with optimized shape

- Optimized by finite element analysis

- Avoids fretting on the cylinder cup

- Prevents external leakage

- Special strengthening procedure to avoid fissures

- Highly exposed areas treated using autofrettage

Central valve – combined suction and discharge

- Compact design

- Full metal execution

- Different surface treatments

- Optimized flow

- Easy maintenance

Advanced Plunger Design

- Plunger quality assured by Burckhardt Compression

- Conus plunger coupling for flexible connection of plunger and crosshead

- Auxiliary crosshead to eliminate undesired plunger movement

- Plunger temperature and vibration monitoring