Operational Flexibility

Highest Operational Flexibility

Best Suited for All Kinds of Process Gases and Parameters

| Process Gas | Operational Challenge | Compressor Solution |

| LNG boil-off gas |

|

|

| Other cryogenic gases |

|

|

| H2S / CO2 content of the gas |

|

|

| Different gases at the same time |

|

|

| CO2 for re-injection |

|

|

The uniqueness of the Laby®-GI Compressor is also reflected by its flexible performance range allowing very simple operation and control. No other compressor can be operated as effectively over such a wide range of process duty parameters. For example, the discharge pressure necessary for fuel gas system supply, is automatically available independent of:

- Alternating suction gas conditions (temperature, pressure, composition)

- Part load condition – highly energy-efficient from 0-100% capacity

- Specific application process requirements

Unique technical features implemented during the compressor development and our decades of compressor know-how are the foundation of the Laby®-GI’s flexibility.

Customization of selected compressor design elements for optimized system operation and control is one of the key competences of Burckhardt Compression. This unique compressor design together with our engineering expertise and system know-how can be applied to your specific application to provide an individual solution:

- Side streams can be taken out at a specific interstage pressure

- Different compression duties on a single compressor frame (eg. separate cylinder used for natural gas compression and closed circuit refrigerant systems)

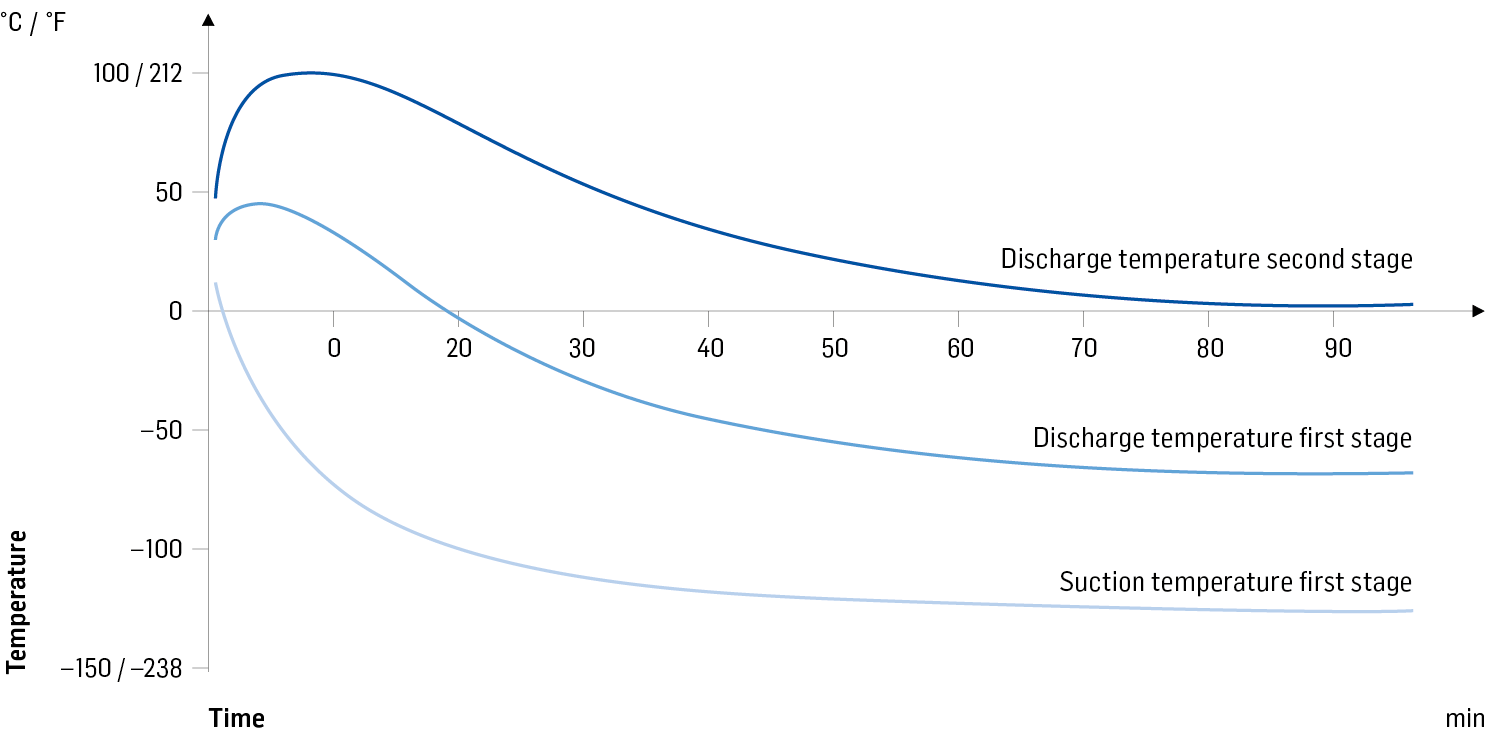

Warm Start-Up Diagram

Simple Capacity Control Concept

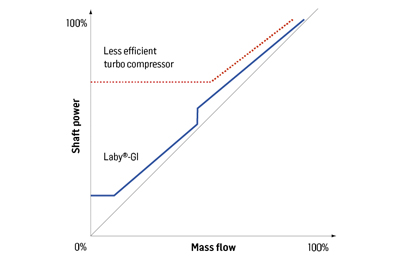

The red dotted curve shows the performance of the capacity control on a turbo compressor, typically realized with adjustable inlet guide vanes. This arrangement allows an efficient control of the mass flow in a limited range. Below this range, the shaft power remains more or less constant. This results in comparably high energy consumption at low capacity.

The blue curve shows the result of the capacity control of the Laby®-GI Compressor with conventional valve unloaders and by-pass regulation almost following the optimum line of turn-down efficiency.