BCS Process Gas Compressors

BCS Process Gas Compressors

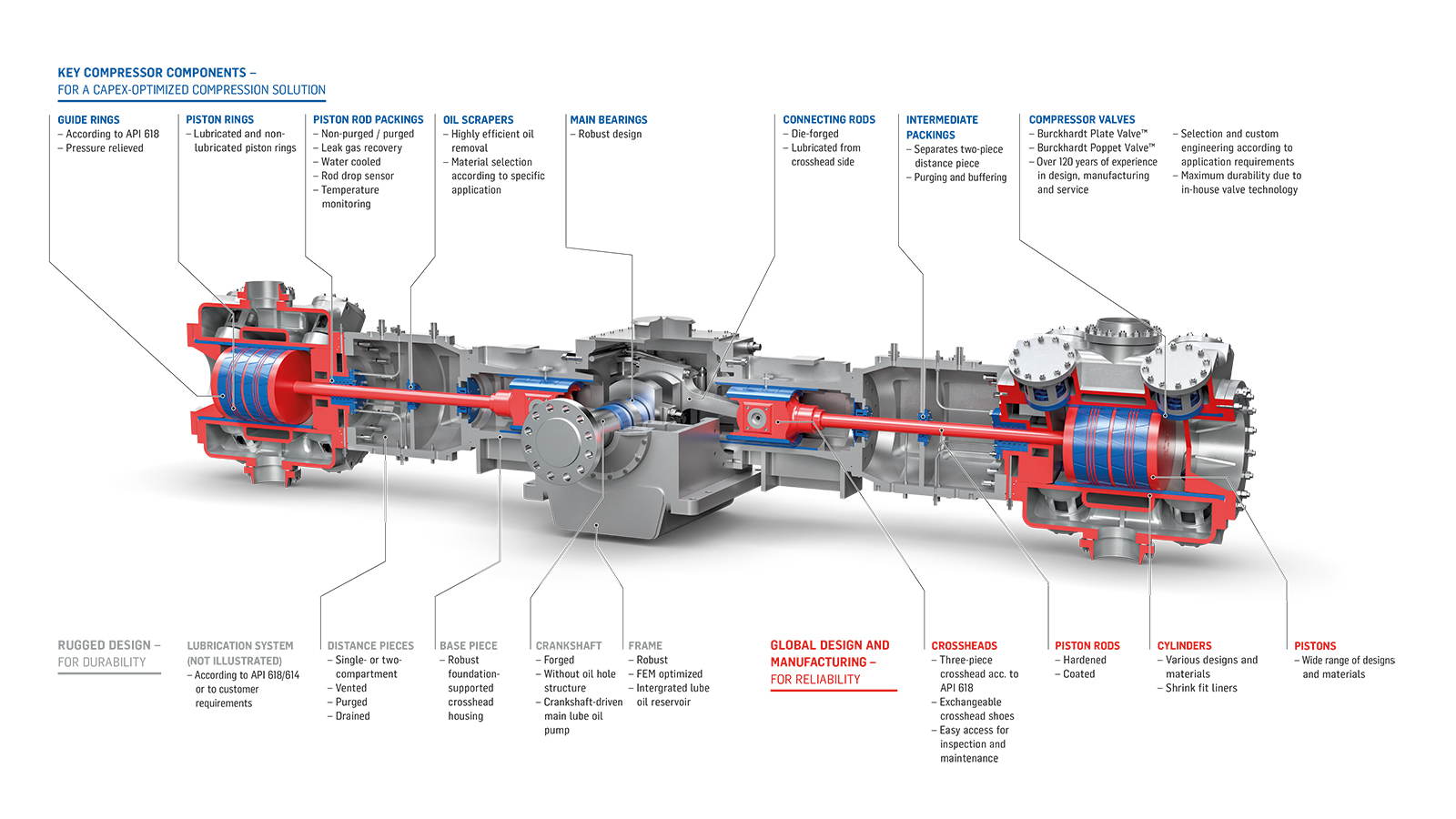

BCS Process Gas Compressors are available up to 200 bar/2’900 psi (lubricated) and 70 bar/1’015 psi (non-lubricated) discharge pressure. The modular compressor design enables cost-efficient engineering and manufacturing resulting in a capex-oriented compressor system, according to API 618 requirements. Services and spare parts management is available worldwide through the global Burckhardt Compression network.

The Right Solution for Your Application

- API 618 compliant Process Gas Compressors from 42 to 1’250 kN gas load (9’448 – 225’000 lbs)

- Proven technology since over 25 years

- State of the art processes and fabrication

- Bare compressor to turnkey solutions

- Capex-optimized design

- High degree of standardization

- Short lead time

- Easy maintenance

- Integrated in the Burckhardt Compression global service and spare parts network

Over 25 Years of Proven Technology

| Type | No. of references |

| P/D 3.5 (42 kN) | 210 units |

| D/M 6.5 (65 kN) | 236 units |

| D/M 10 (100 kN) | 496 units |

| D/M 12 (120 kN) | 261 units |

| D/M 16 (160 kN) | 231 units |

| D/M 20 (200 KN) | 353 units |

| D/M 25 (200 KN) | 168 units |

| D/M 32 (320 kN) | 385 units |

| D/M 45 (450 kN) | 213 units |

| D/M 80 (800 kN) | 217 units |

| D/M VL (1000 kN) | 6 units |

| D/M HE (1 250 kN) | 55 units |

Fast Delivery Through In-House Manufacturing

- 4 machining shops

- 1 assembly workshop

- Packaging workshop

- Own foundry

- Fast delivery: Bare shaft compressors 6 – 10 months, Packages 8 – 12 months

- New factory opening in 2020

State of the Art Quality and In-House Testing Facilities

- Mechanical and chemical testing competencies

- Destructive and non-destructive testing

- Metallographic examinations

- Various calibration possibilities

- Facilities and processes certified acc. to: ISO 9001:2015, ISO 14001:2015, OHSAS 18001:2007, API Q1

- Laboratory accreditation certificate acc. to ISO/IEC 17025:2017

Flexibility Through In-House Foundry

- ASTM materials for international markets

- Short lead times through flexible slot-planning

- Best material quality through state of the art processes

- Optimized carbon foot-print, using electric furnaces

- On-Site materials lab

Diverse Configuration Options

- Bare-shaft compressors

- Foundation mounted compressor systems

- Integrated compressor systems, fully engineered in-house

- Packaged and fabricated in-house for various markets: sea-can packages, single-lift packages, multi-lift packages

Extensive Product Portfolio

| Type | Max. combined rod load [kN/lbs] |

Throws | Standard strokes [mm/in] |

Max. rotating speed [rpm] |

| P/D 3.5 | 42 / 9 448 | 1, 2 | 180 / 7.08 | 700 |

| D/M 6.5 | 65 / 14 612 | 2, 4 | 240 / 9.44 | 520 |

| D/M 10 | 100 / 22 480 | 2, 4 | 240 / 9.44 | 520 |

| D/M 12 | 120 / 26 977 | 2, 4 | 240 / 9.44 | 512 |

| D/M 16 | 160 / 35 969 | 2, 4 | 280 / 11.02 | 450 |

| D/M 20 | 200 / 44 992 | 2, 4, 6 | 280 / 12.59 | 450 |

| D/M 25 | 250 / 56 202 | 2, 4, 6 | 280 / 12.59 | 450 |

| D/M 32 | 320 / 71 938 | 2, 4, 6 | 280, 320 / 11.02, 12.59 | 420 |

| D/M 45 | 450 / 101 164 | 2, 4, 6 | 315, 350 / 12.40, 13.77 | 400 |

| D/M 80 | 640 / 143 962 | 2, 4, 6 | 315,350 / 12.40, 13.77 | 360 |

| D/M VL | 800 / 179 847 | 2, 4, 6 | 320, 350 / 12.59, 13.7 | 360 |

| D/M HE | 1 000 / 224 962 | 2, 4, 6 | 320, 350 / 12.59, 13.77 | 333 |

Flexible Project Setups – Adjusted to Your Needs

- Depending on customer needs, different project setups and scope splits feasible

- Close collaboration with other global BC subsidiaries and entities

| Flexible setups | BCS Compressor | Burckhardt Compression |

| Bare-Shaft Compressor | X | |

| Procurement of Auxiliaries</td align=”center”> | X | X |

| Project Management | X | X |

| Project Engineering | X | X |

| Quality Assurance Auxiliaries | X | X |

| Services, Spares and Maintenance | X |