Hydrogen trailer filling

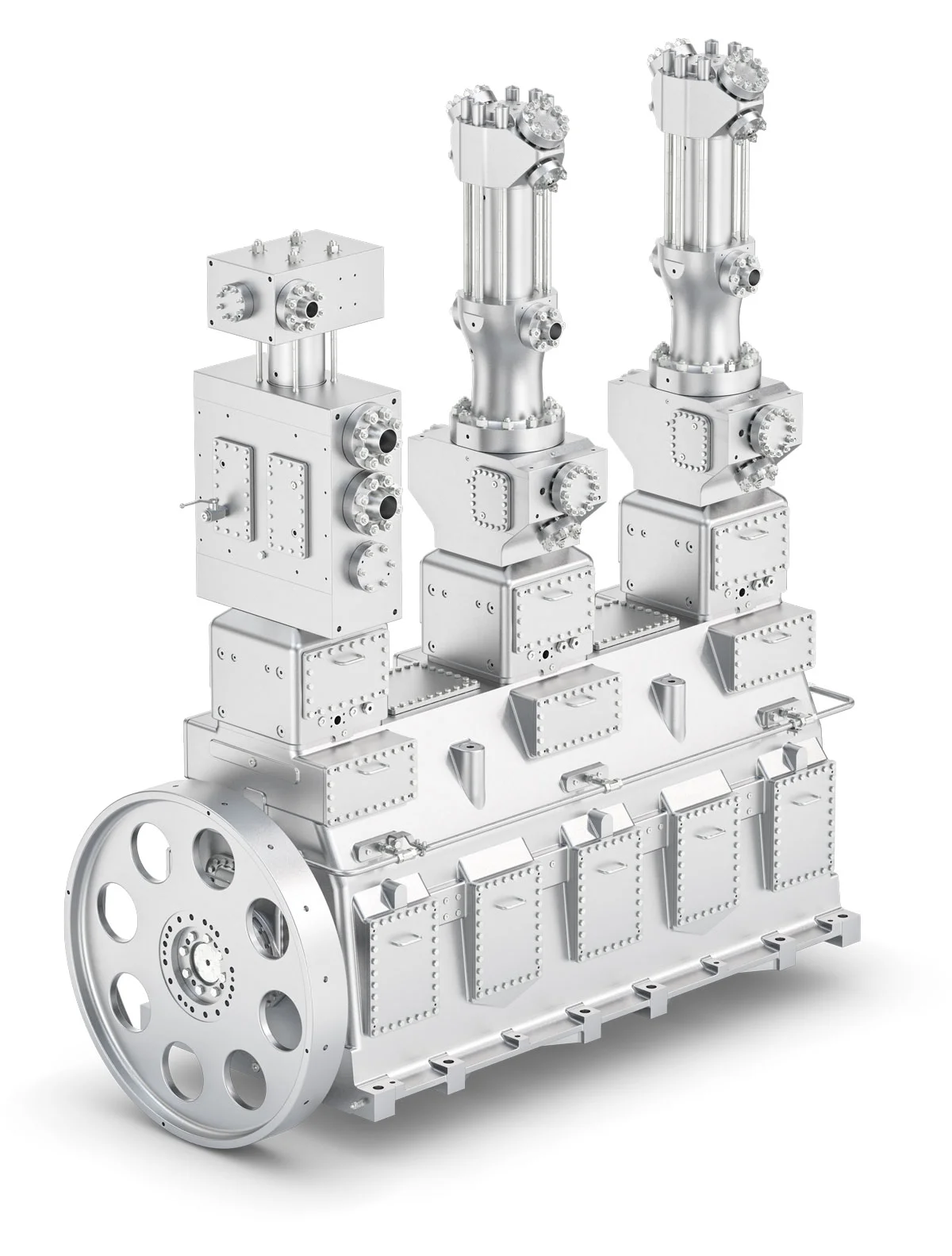

Pretested and proven compression solution for your high-pressure hydrogen trailer filling

Carefree high-pressure trailer filling with dry running compression solution up to 550 bar, from fully standardized up to fully engineered-to-order (ETO) solutions to fill at different tube trailer pressures

Your benefits

Highest Purity

Independent on the selected compression solution, highest H2 purity is granted due to non-lubricated operation

Seamless Project Execution

Modularized, standardized, and type-tested solutions - Our experience is your profit

Features

- Built to handle high-pressure at highest gas purity

- Designed to cover H2 production range from 2 to 50 MW Electrolysis capacity at trailer filling pressure

- Longest MTBO for our non-lube piston compressor solutions

- Worldwide Service Network assures local support

Hydogen fuel stations

Hydrogen fuel stations for heavy-duty vehicles demand a large amount of hydrogen. Shipped by GH2 trailers, the delivered amount of hydrogen requires compressor systems with a sufficient flow.

Diaphragm compressors are the preferred solution for smaller production and filling application at moderate H2 flow, whereas at higher increased amount of hydrogen requires compressor systems with a sufficiently high flow. Non-lubricated Piston compressors are the preferred solution for larger applications.

For both compression solutions, we are offering an oil-free high-pressure compressor systems maintaining hydrogen quality according to SAE J-2719.

Get in touch

Talk to our specialists.

Compressors

Downloads

- Compression solutions for hydrogen mobility and energy EN pdf 11.02MB

More languages

No other languages available

- Fully standardized compression solution for hydrogen trailer filling Containerized diaphragm compressor unit MD10 EN pdf 1.62MB

More languages

No other languages available

- Oil-free hydrogen compression solutions for high-pressure applications EN pdf 1.67MB

More languages

No other languages available