Laby K / D compressors

AI Summary

The Laby® gas-tight compressors offer high efficiency, reliability, and low total cost of ownership, making them suitable for demanding industrial applications. Their unique contactless labyrinth sealing system ensures oil-free compression with no mechanical wear, resulting in longer compressor life, reduced maintenance, and the highest gas purity. These compressors can handle a wide variety of gases, including dry, humid, cryogenic, contaminated, reactive, explosive, corrosive, and toxic types. Their robust and simple design supports high reliability and availability, ideal for critical uses in industries such as gas transport, petrochemical, and industrial gas production. Tailored solutions are available for applications like natural gas handling, reliquefaction, and polypropylene and polyethylene production. Technical specifications cover various models (K-Types and D-Types) with differing crank numbers, stroke lengths, speeds, power ratings, and dimensions to suit diverse operational needs.

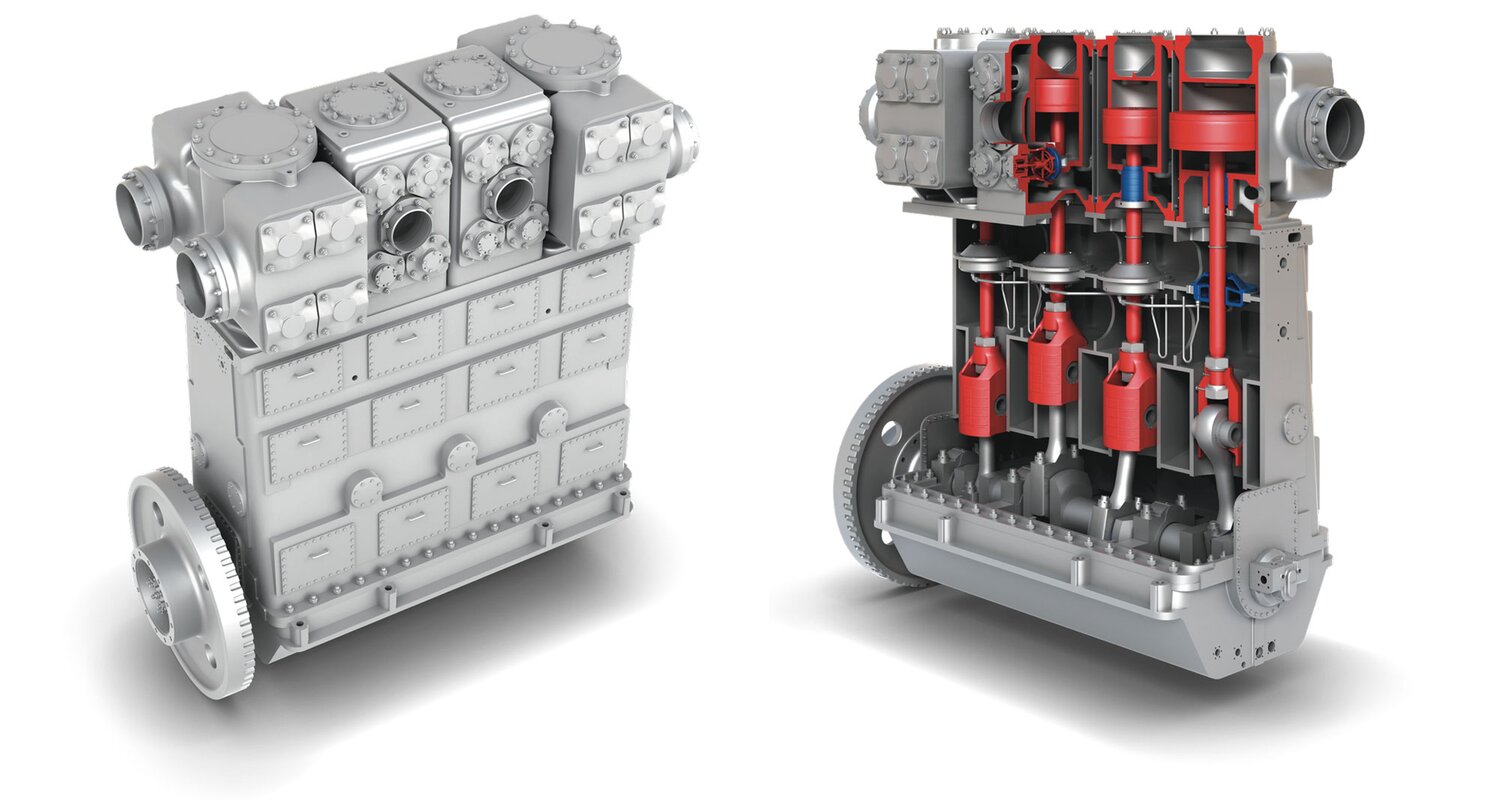

Gas-tight compressors - high efficiency at low cost and proven design

Our Laby® compressors are engineered to deliver exceptional performance and reliability, making them the ideal choice for a wide range of demanding applications.

Your benefits

- Contactless Labyrinth Sealing

This unique sealing system ensures there is no mechanical wear, leading to longer compressor life and reduced maintenance costs. - Highest gas purity

The labyrinth sealing allows for oil-free compression, No contamination of highly pure gases with oil or abrasives from piston rings or rider rings. - Handling Complex Gases

The compressor is designed to handle a wide range of gases, including bone-dry, humid, cryogenic, dirty, dust-laden, contaminated, reactive, explosive, corrosive, and toxic gases. - High Reliability

The design and materials used in the Laby Compressor ensure high reliability and availability, making it suitable for critical applications. - Low Total Cost of Ownership

Due to the contactless sealing and separation of sealing and guiding elements, the compressor requires minimal maintenance.

Features

- Labyrinth Sealing System

This system provides contactless and oil-free compression, which minimizes wear and maintenance. - Versatility

The compressor can handle various gases and is used in multiple industries, including gas transport and storage, petrochemical, and industrial gas applications. - Robust Design

The Laby compressor has a simple and rugged design, which contributes to its durability and long service life.

Tailored solutions

- Natural gas handling and reliquefaction

- Polypropylene production

- Polyethylene production

Get in touch

Talk to our specialists.

Downloads

- Laby compressors brochure EN pdf 7.13MB

More languages

No other languages available