PROGNOST-NT - condition monitoring

AI Summary

PROGNOST®-NT is a leading condition monitoring system designed for rotating equipment, helping machine operators extend Mean Time Between Maintenance (MTBM) through early failure detection. Its Predictive Intelligence module predicts component lifetimes to optimise maintenance and reduce operating costs. Key features include early detection of faults to protect personnel and assets, piston rod position monitoring for mechanical condition assessment, detailed root cause analysis with continuous signal recording, and advanced signal plausibility checks to avoid false alarms. The system integrates machine protection with PROGNOST-SILver sensor data acquisition and SIL3 analyses, supporting various signal inputs such as speed, vibration, displacement, pressure, and temperature. It offers automated diagnostics using a damage pattern database with over 200 patterns, especially for reciprocating compressors. Users benefit from an intuitive graphical interface via PROGNOST-NT VISU and a cloud monitoring suite for easy visualisation. The solution aims to enhance equipment availability, safety, and maintenance efficiency.

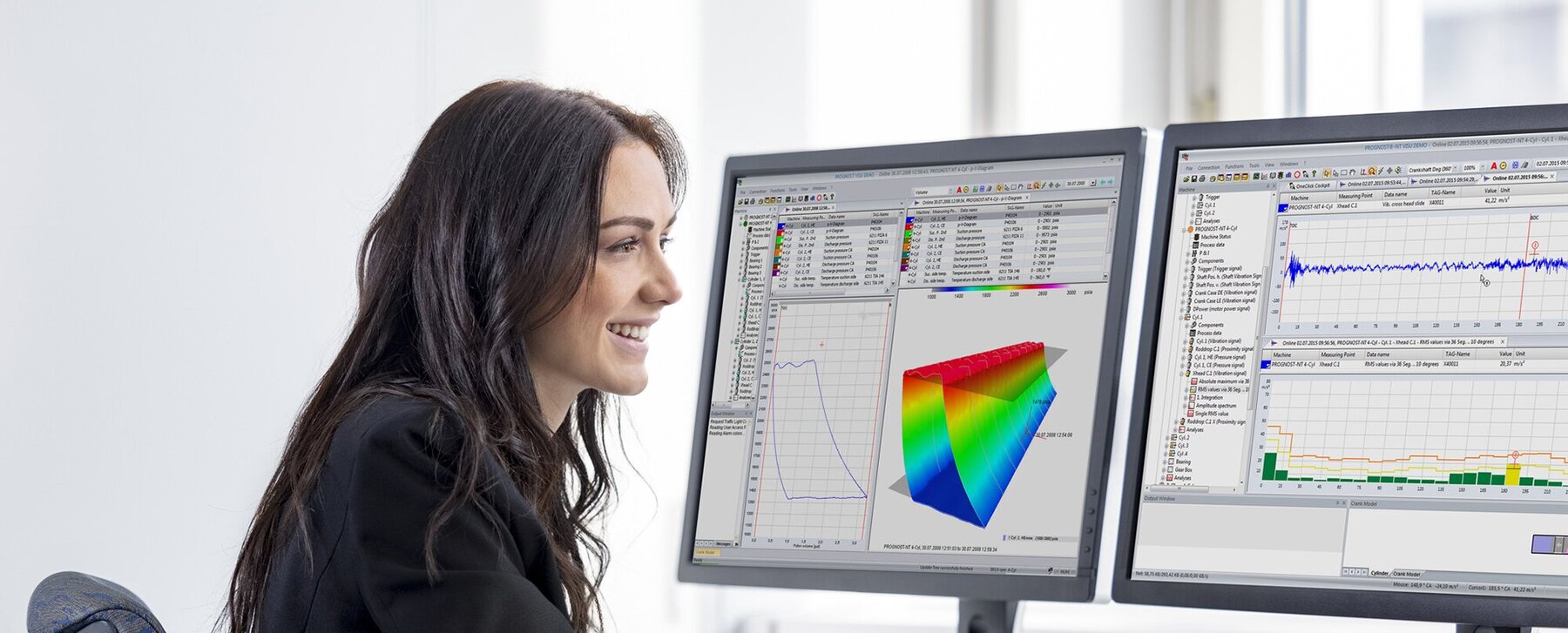

Online diagnostic system with integrated machinery protection

PROGNOST®-NT is the No. 1 condition monitoring system for rotating equipment

Machine operators who need to extend their MTBM (Mean Time Between Maintenance) through early failure detection rely on PROGNOST-NT.

Your benefits

- Enhance availability: The Predictive Intelligence software module minimizes operating costs by predicting the maximum component lifetime and optimizing maintenance planning

- Early failure detection: Detect issues at the earliest possible stage and limit the consequences of serious failures to protect personnel, the environment, and assets

- Piston rod position monitoring: For rider ring wear calculation and to monitor the mechanical condition of the piston rod, piston, and crosshead connections

- Detailed root cause analysis: An automatic 10-minute ring buffer continuously records uncompressed signal data of all connected sensors (both hardwired and DCS connected)

- Signal plausibility checks: Advanced signal processing prevents false alarms triggered by broken wires, loose sensors, and other electrical issues

Features

- Predictive Intelligence: Accurate prediction of the remaining useful lifetime of valves and packings using artificial intelligence

- Machine protection integrated: PROGNOST-SILver sensor data acquisition and SIL3 machine protection analyses with relay output onboard

- Different signal inputs: Signal processing for speed (rpm), vibration (acceleration, velocity), displacement, pressure, and temperature

- Automated machine diagnostics with damage pattern database: Pattern recognition with an integrated diagnostic database including 200 patterns, especially for reciprocating compressors

- Intuitive graphical user interface: The PROGNOST-NT VISU plus the cloud dashboard are the customer-oriented visualization solutions

Get in touch

Talk to our specialists.

Downloads

- PROGNOST®-NT brochure EN pdf 3.16MB

More languages

No other languages available