The global energy transition requires both: renewable electricity and transportable green molecules, such as hydrogen or ammonia. Compressors are essential for efficiently managing and distributing these gaseous energy carriers. With our comprehensive compression solutions, we are already delivering numerous projects to support the development of this new sustainable energy infrastructure.

Understanding Power-to-X

Power-to-X (PtX) represents a fundamental shift in energy management. It involves converting renewable electricity into various energy forms or chemical compounds, such as hydrogen and ammonia. These energy carriers tackle two of renewable energy’s greatest challenges: the intermittent nature of energy production and the geographic distance between resource-rich regions and high-demand markets. Functioning as mobile renewable energy containers, they connect production hubs in the Middle East, North Africa, Australia, and South America with high-demand markets in Europe, South Korea and Japan. By enabling large amounts of energy to be stored, transported, and utilized in multiple forms, Power-to-X creates a flexibility that purely electrical systems cannot match.

Efficient transportation of substantial hydrogen volumes predominantly utilizes pipelines. However, when pipeline infrastructure is unavailable, alternatives such as green ammonia – produced from renewable hydrogen and nitrogen – emerge as promising solutions. Given the cost sensitivity around transport and storage in the hydrogen economy, precise selection and deployment of compression technology is vital.

Comprehensive compression solutions

Burckhardt Compression delivers tailored compression solutions covering every stage of the PtX value chain, from renewable electricity generation and hydrogen compression to ammonia synthesis, global logistics, and enduse applications. Our extensive compressor portfolio is specifically designed to enhance efficiency and scalability across these diverse applications. In addition to supplying the initial machinery, process consultancy, and project support, our Services Division utilizes its expertise to ensure operational excellence and compressor reliability for our customers. With a global footprint and decades of experience in hydrogen, ammonia and carbon-dioxide compression, we have operational reference projects across all these applications. By highlighting the green ammonia value chain (map on the left), we demonstrate our contributions to the whole value chain with customer examples.

1. Renewable electricity production

Our involvement in the green ammonia value chain begins at renewable energy production sites, where solar and wind farms generate green electricity. Here, our Hyper Compressors play a vital role in producing materials such as ethylene-vinyl acetate (EVA), used in solar panels, and our Process Gas Compressors are the benchmark in the production of polysilicon for photovoltaic cells.

2. Hydrogen generation

Once harnessed, the green electricity enables hydrogen production through electrolysis, splitting water into hydrogen and oxygen. Our compressors ensure the hydrogen meets exact pressure specifications necessary for the next step – ammonia synthesis. Our Laby® Piston Compressors can also compress the emitted oxygen for further use.

3. Ammonia synthesis

During ammonia production via the Haber-Bosch process, hydrogen and nitrogen are combined under pressures of 150–200 bar. Our Process Gas Compressors are specially designed to handle these demanding conditions, significantly improving the efficiency and reliability of ammonia production.

Customer example:

We will be supplying a substantial number of compressors for green ammonia synthesis projects across China. These systems will enhance production efficiency and support the transport of sustainable energy.

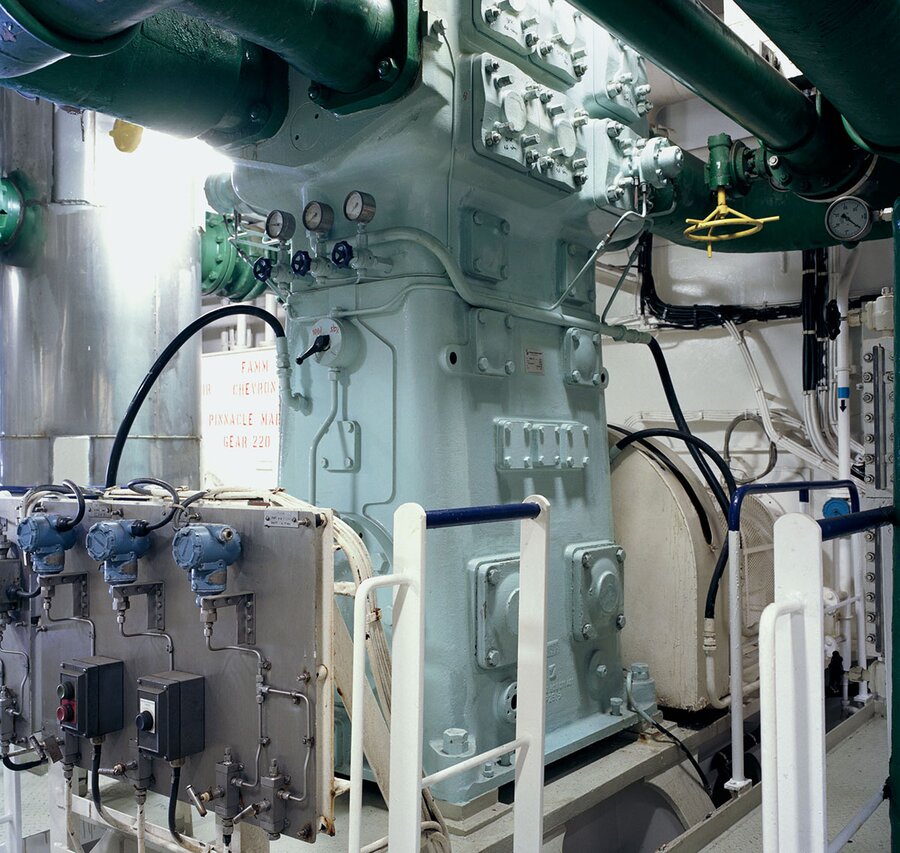

4. Global transport and storage

Following synthesis, green ammonia needs to be safely stored and transported across the seas. Our Laby® Piston Compressors, combined with our expertise in the reliquefication process, play an important role in managing boil-off gas during export, maritime transportation, and import at its destination.

Customer example:

In September 2024, we secured an order to supply boil-off gas compressors for very large ammonia carriers (VLACs), each capable of transporting 63,500 tons of ammonia. This milestone strengthens the infrastructure for global renewable energy distribution.

5. End-use applications

Upon arrival at its destination, the ammonia can be used directly in applications such as power generation or fertilizers. It can also undergo “cracking”, a process that converts it back into hydrogen and nitrogen. The recovered hydrogen can be stored for future use, injected into pipelines, or utilized directly in industrial processes and mobility applications. Our Process Gas Compressors play a crucial role in this step, compressing the gases for efficient distribution. Additionally, our hermetically sealed Diaphragm Compressors ensure gas purity, meeting stringent requirements for high-pressure applications.

Customer example:

We are providing oil-free hydrogen (tail-gas) compressors for five European sites. These compressors are part of the cracking process plant and will enable the recovery of the transported hydrogen.

Customer example:

We are commissioned to supply a Process Gas Compressor for a project aimed at adapting existing gas caverns and above-ground facilities for hydrogen storage. This initiative is part of Europe’s broader effort to enable a hydrogen economy, ensuring the infrastructure is ready for large-scale hydrogen storage and utilization.

Outlook: Power-to-X as key enabler to reach our strategic objectives

The global shift toward sustainable energy creates significant business opportunities, and Burckhardt Compression is positioned strategically within the expanding PtX value chain. As renewable energy technologies grow worldwide, the demand for dependable compression and gas management solutions will continue to rise. Supported by the growth of this sustainable energy infrastructure market, we aim to reach a share of 40% of our orders dedicated specifically to energy transition applications by 2027.

You can read more about the important role of green molecules in our Essentials magazine on page 36.

Latest articles

Burckhardt Compression announces leadership change in Services Division

Ad hoc announcement pursuant to Art. 53 LR

January 12, 2026