Cost effective solution: Overhaul of 2nd-hand Laby setting its clock back to zero hours

Arxada, a global specialty chemicals business with leading positions in Microbial Control Solutions (MCS) and Specialty Products Solutions (SPS) needed to produce Methylbutynol, a feedstock for vitamin production.

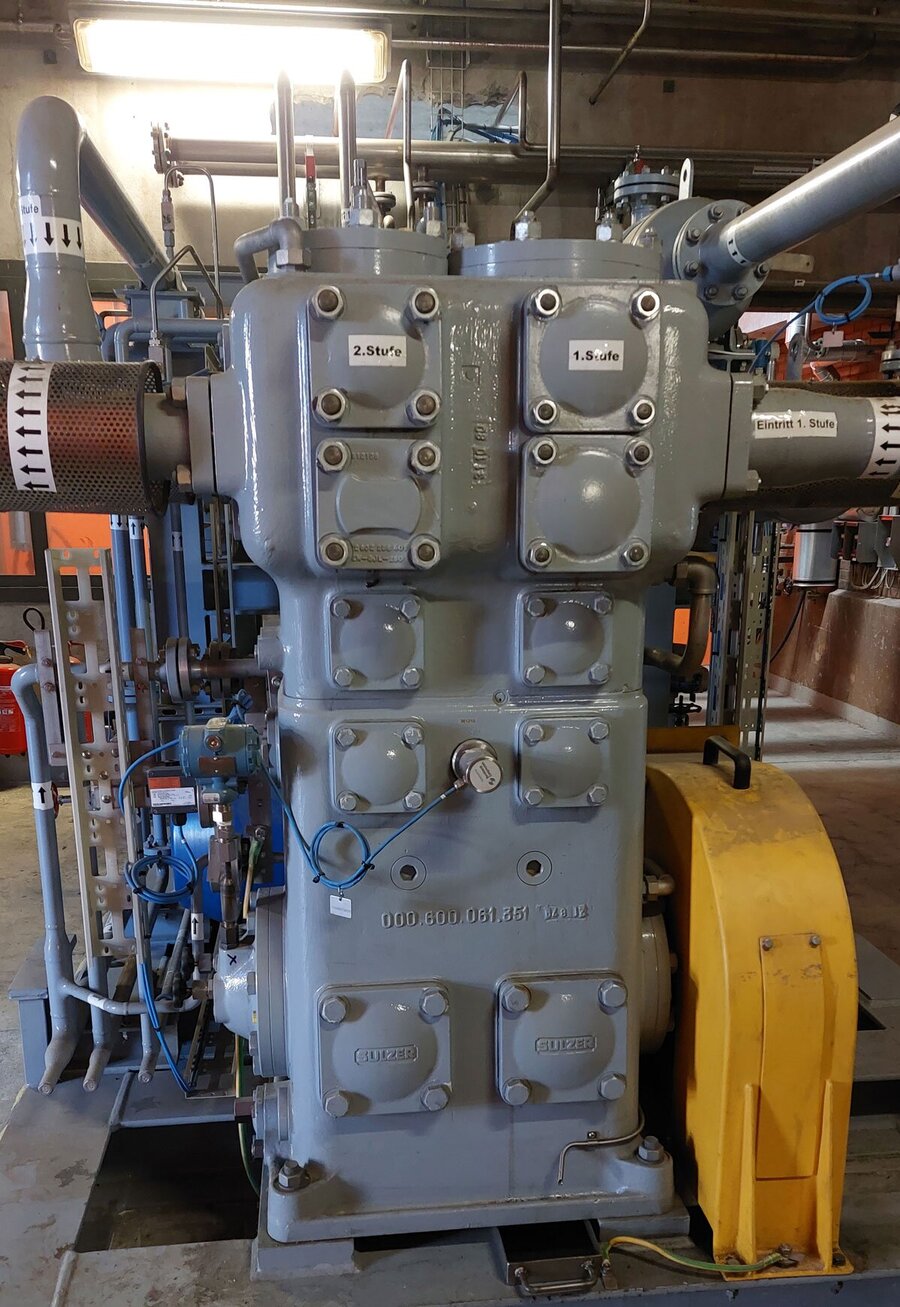

An additional production line was necessary and Arxada turned to Burckhardt Compression to find the best and most cost-effective solution. Technical and commercial discussions resulted in the offer of a skid-mounted, 2nd hand Laby® compressor that Burckhardt Compression would overhaul to set its clock back to zero hours.

We are very satisfied with our customized compressor skid and its retrofitted Laby® compressor. Burckhardt Compression has provided us with a cost-effective, reliable and high-quality solution. We can look back on a long-standing partnership, which we will continue to build on in the future.

Claudio Furrer, Plant Engineer, Arxada AG

Customer challenges

Technical data

| Manufacturer | Burckhardt Compression |

|---|---|

| Type | Laby® 2K90-2B |

| Power | 55 kW / 74 hp |

| Speed | 820 rpm |

| Gas | NH3 |

| Suction pressure | 2 bar / 29 psi |

| Discharge pressure | 14 bar / 203 psi |

Our solution

- Overhaul of a 2K90-2B 2nd hand Laby® from Burckhardt’s compressor pool

- Complete skid design, calculations and production to fit operating data

- Pressure test of crankcase cylinder and cylinder cover

- Machining of flywheel and skid design for belt-driven compressor

- Assembly, full test run and painting

- New specifications for the complete skid assembly

- Installation and commissioning at customer site

Customer benefits

- Refinery

- Success Stories

- Laby 2K70 compressors

- Overhauls and dry docks

- Revamps and upgrades

- Installation and commissioning

- Emission management solutions

Latest articles

Burckhardt Compression announces leadership change in Services Division

Ad hoc announcement pursuant to Art. 53 LR

January 12, 2026