Maximizing hydrogen production efficiency with UP! Insight

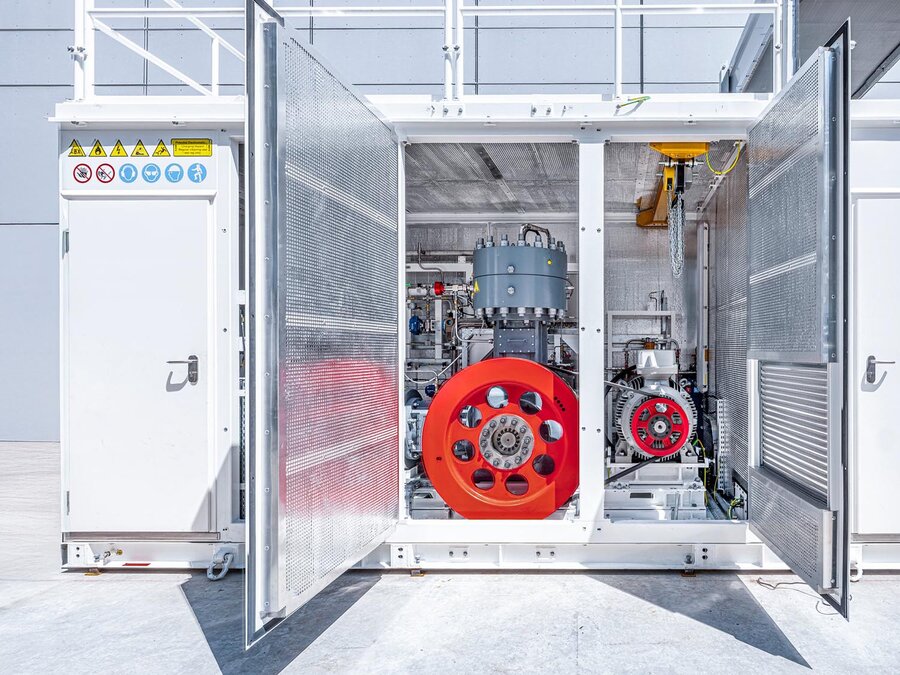

Our customer Wasserstoffproduktion Ostschweiz AG (WPO) operates a state-of-the-art hydrogen production facility in St. Gallen, Switzerland. Powered by hydropower, the plant produces up to 250 tons of CO₂-neutral hydrogen annually - enough to fuel approximately 40 long-haul trucks. To fill trailers efficiently, WPO relies on the MD10-L diaphragm compressor package from Burckhardt Compression. To gain full visibility into compressor performance and maximize availability, the cloud-based monitoring solution UP! Insight has been implemented.

This intelligent system continuously analyzes PLC signals, providing WPO with a real-time overview of compressor status, along with timely alerts and service recommendations. Our technical support team has full access to the data at any time, enabling them to assist with clarifications, review historical trends, identify root causes, and offer expert guidance. This seamless collaboration has significantly enhanced compressor uptime, contributing to greater operational efficiency and reliability for WPO.

“With UP! Insight, we’ve created a solution that transforms raw compressor data into actionable intelligence. It’s not just about monitoring - it’s about enabling smarter decisions, faster interventions, and ultimately, maximizing equipment availability.”

Philipp Wolschner, Digital Product Manager

Customer challenges

- Lack of real-time visibility into compressor condition

- Difficulty in identifying root causes of incidents

- Delayed identification of component failures

- Inefficient planning of service interventions

Technical data

| Manufacturer | Burckhardt Compression |

|---|---|

| Type | MD10-L |

| Power | 90 kw / 120 hp |

| Speed | 480 rpm |

| Gas | Hydrogen |

| Suction pressure | 29 bara / 420 psia |

| Discharge pressure | 504 bara / 7’309 psia |

| Lubrication | non-lube |

Our solution

- UP! Insight - cloud-based real-time monitoring

By analyzing PLC signals in real time, UP! Insight provides a holistic view of the compressor’s operational status. The system automatically notifies the customer of anomalies and delivers tailored service recommendations.

- 24/7 technical support and data assessments

Our expert support team is available to assist with alarm clarification and troubleshooting. In addition, they perform comprehensive data assessments, analyzing historical data and operating patterns to identify root causes and recommend targeted corrective actions.

- Service planning support

By monitoring runtime and component status, UP! Insight enables more efficient planning of field service visits and resource allocation. It also supports data-driven decisions on whether the compressor can continue operating safely.

- Component-level diagnostics

The system successfully identifies issues such as pressure control valve damage and cooling system inefficiencies by analyzing pressure and temperature trends - allowing for timely and targeted interventions.

- User-friendly dashboards

All compressor data is continuously updated and accessible via intuitive dashboards. The customer can view all PLC alerts in a filterable logbook, create custom P&IDs, and monitor the parameters most relevant to his operations.

Customer benefits

support - powered by UP! Insight.

- Reduced unplanned downtime

- Faster root cause identification and resolution

- Optimized field service planning and resource use

- Remote access to compressor operational data anytime, anywhere

- Improved decision-making on whether to continue compressor operation, supported by real-time visibility into component status

Latest articles

Burckhardt Compression announces leadership change in Services Division

Ad hoc announcement pursuant to Art. 53 LR

January 12, 2026