Piston rod packing revision reduces lube oil consumption drastically

Indian Oil Corporation Limited operates a large fleet of reciprocating compressors, including several supplied by Burckhardt Compression. Among them, one Laby® compressor used in a propylene application was not performing at its full potential. Over time, maintenance gaps had led to issues within the lube oil system, resulting in reduced reliability and increased maintenance costs.

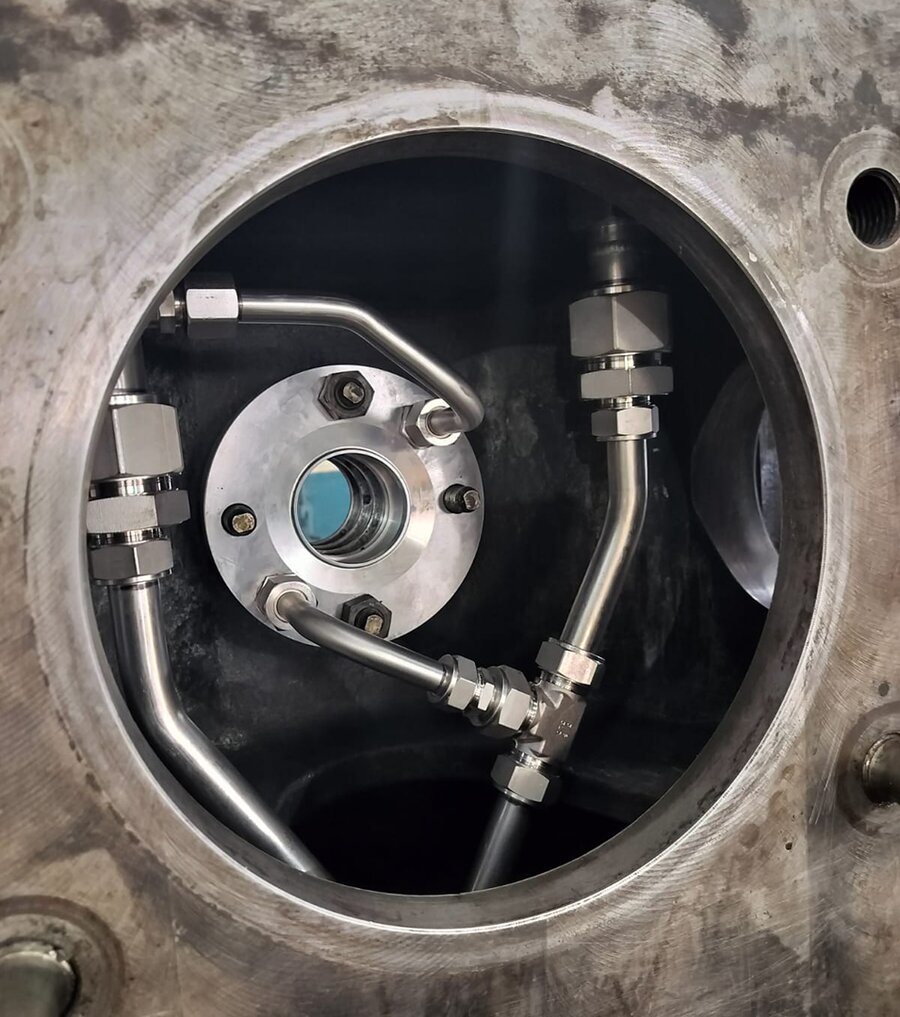

Faced with these challenges, the customer approached Burckhardt Compression India with a clear objective: to resolve the recurring issues permanently and enhance the overall reliability and efficiency of the compressor. Our team conducted a thorough assessment and identified the root causes affecting performance. Leveraging our deep expertise in reciprocating compression and propylene-specific applications, we implemented a solution featuring a specially designed rod packing system. This advanced design addresses the unique demands of propylene compression, significantly improving sealing performance and reducing wear.

“We sincerely appreciate Burckhardt Compression for their proactive approach and clear technical guidance during the piston rod packing revision. Following the successful validation of the modification, we proceeded to place an order for implementing the same solution on another compressor. This upgrade has significantly enhanced compressor reliability and strengthened our trust in Burckhardt Compression’s engineering expertise. Thanks to the team in India for delivering a valuable and effective solution.”

Indian Oil Corporation Limited

Customer challenges

- High consumption of lube oil and wear parts (oil scraper rings & rod packing)

- Frequent unplanned maintenance

- Limited maintenance windows due to single-line, critical operation

- Significant financial impact to be reduced or eliminated

Technical data

| Manufacturer | Burckhardt Compression |

|---|---|

| Type | Laby® 3K-160-2D |

| Power | 540 kW / 724 hp |

| Speed | 744 rpm |

| Gas | Propylene C3H6 |

| Suction pressure | 0.5 barg / 7.3 psig |

| Discharge pressure | 21 barg / 305 psig |

| Lubrication | yes |

Our solution

Aligning execution with operational priorities

To meet critical operational requirements while maintaining uninterrupted progress, a detailed project plan was developed with a streamlined 24/7 schedule. This approach was carefully designed to minimize downtime and ensure that every phase of the project moved forward continuously, without compromising quality or safety.

Supplying all necessary components

We provided a complete set of high-quality spare parts specifically tailored for this application to ensure a smooth and efficient rod packing revision. This comprehensive spare parts package was carefully selected to match the technical requirements of the upgraded rod packing design, ensuring full compatibility and optimal performance.

Maintaining momentum throughout the project timeline

It is essential to secure the availability of all required spare parts in advance of the job start to ensure a smooth and uninterrupted execution of the project. This proactive approach minimizes the risk of delays caused by last-minute procurement issues or unforeseen supply chain disruptions.

Timely completion, minimized downtime

The rod packing modification was successfully completed within the planned timeframe, demonstrating precise execution and effective project coordination. This critical upgrade was carried out without disruption to surrounding operations, reflecting a strong alignment between engineering planning and on-site implementation.

Customer benefits

- Compressor successfully returned to operation following installation of the revised rod packing

- New packing solution validated over a 6-month operational period

- Lube oil exchange decreased from four times to only once a year

- Oil carryover issue fully resolved, process gas stays clean

- Extended service life of key wear parts (oil scraper rings & rod packing) to meet maintenance strategy

- Compressor reliability and operational stability significantly improved

- Compressor sealing solutions

- Compressor packings

- Repair services worldwide

- Technical improvements

- Success Stories

Latest articles

Burckhardt Compression announces leadership change in Services Division

Ad hoc announcement pursuant to Art. 53 LR

January 12, 2026