Supporting energy security and energy transition with our Laby®-GI Compressor technology

The global supply of liquefied natural gas (LNG) has rapidly increased in the past years as countries aim to increase their energy supply in a sustainable way, independent of geopolitical tensions. At the same time, decarbonization commitments of the marine industry have positioned LNG as a transition fuel for maritime fleets. As both trends intensify the future demand for LNG, our Laby®-GI Compressor technology is expected to play an indispensable role in making this happen.

Rapid LNG capacity expansion on the back of geopolitical uncertainty

In the past 10 years, natural gas has been the fastest growing source of energy as it is relatively affordable and emits 20 to 25% less CO2 than oil or coal during combustion.

During this period, liquefied natural gas (LNG) has also been the fastest-growing method for transporting and storing natural gas, making it a highly versatile, globally traded energy source, as opposed to gas pipelines which face territorial restrictions during periods of geopolitical disagreements. To meet future demand, new liquefaction projects underway are anticipated to increase LNG supply by 193 million tons per annum from 2024 through 2028. This marks the most rapid capacity expansion in the global LNG industry, with a 40% increase occurring within just five years1.

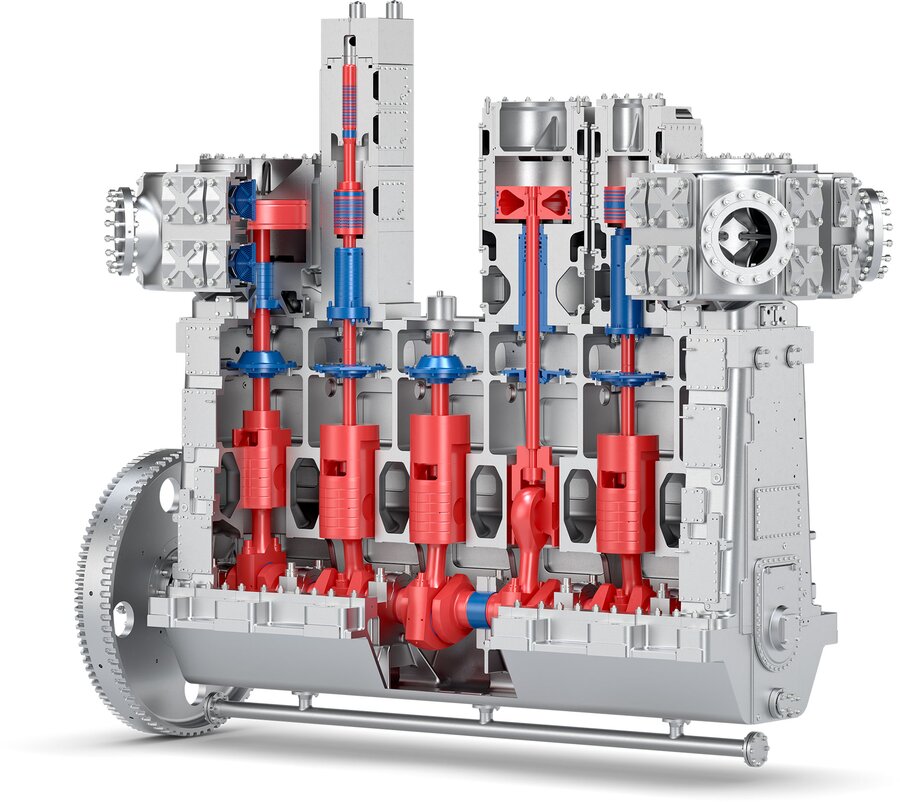

Laby®-GI Compressors are essential in handling the LNG boil-off gas

LNG carriers are large ships, which transport the liquefied gas across the sea to the country of import where it is re-gasified for energy consumption. As gas is stored at –160 °C, much lower than the surface temperatures on the carrier, it continuously evaporates. This occurrence is called the “boil-off gas” (BOG). LNG carriers either run on a low- or high-pressure propulsion engine, and this defines the type of compressor needed to handle the BOG. Our Laby®-GI Compressor technology manages the BOG on high-pressure LNG carriers by injecting it into the engine as propulsion fuel, into the generator set to produce electricity on board, or into a reliquefication system.

Launched in 2013 and developed in close cooperation with MAN B&W and leading Korean shipbuilders, the 6-crank, fully balanced crank gear design allows smooth and vibration-free compressor operation. The technology minimizes the requirements for the machinery foundation design and transmits only very limited forces and moments to the ship structure. Additionally, a mechanical shaft sealing in combination with a pressure-resistant crank gear avoids the loss of gas to the atmosphere. This saves tons of methane emissions every year and contributes to the reduction of greenhouse gas (GHG) emissions.

Strong market position among high-pressure LNG carriers

Today, out of 76 existing LNG carriers running on a high-pressure engine, 65 of them have our Laby®-GI Compressors installed. These compressors have accumulated more than 2.5 million operating hours and contributed to the energy availability and security in many European and Asian countries.

Further innovating with oil-free, dry-running compressor technology

In the first version of the Laby®-GI, a lubricant was used to seal off the gas. Due to small quantities of oil being carried over from the compressor’s cylinders, LNG carrier operators started noticing issues in other parts of their equipment.

That is why, in 2019, Burckhardt Compression introduced the world’s first completely oil-free reciprocating high-pressure fuel gas compressor. By 2024, the first compressors of the latest generation of the Laby®-GI, the LP250V, entered service. With this technology, we are the only manufacturer able to compress methane to 300 bar in a large compressor system without cylinder lubrication. This design improves gas quality and overall compressor performance, while lowering costs for cylinder lubrication oil and maintenance. Since 2021, a total of 58 compressor units of the LP250V were ordered for 28 LNG carriers.

© BW Group

Future outlook: new regulations favor high-pressure dual-fuel engines

January 1, 2025, marks the start of the implementation of the FuelEU regulation. It imposes mandatory reductions of greenhouse gas emissions (GHG) from transport ships starting at 2% in 2025 and gradually increasing through the years until reaching an 80% reduction in 2050. This may have a direct impact on the selection of engines for LNG tankers. Due to their operating principle, low-pressure engines have a higher methane slippage rate, while high-pressure engines, such as the ME-GI compatible with our Laby®-GI Compressor, have close to zero methane slippage. For LNG fleet owners to reduce their GHG emissions, it will be increasingly attractive to operate a carrier that runs on a high-pressure engine. This should provide additional opportunities for our Laby®- GI compressor technology. This trend is confirmed by noting that, in October 2024, MAN B&W announced it is discontinuing its low-pressure propulsion engine line for LNG carriers. We are now developing a new compressor platform for LNG tankers to further enlarge our portfolio and satisfy the expected market demand. Our Laby® and Laby®-GI Compressors are not only used for different types of cargo ships and carriers, but are also needed onshore for LNG import and export terminals. As the demand for LNG continues to increase in the coming years, our compression solutions will continue to support energy availability, security, and sustainability in many countries.

You can read more about the important role of the Laby®-GI Compressors in our Essentials magazine on page 26.

1Source: Global LNG Outlook 2024–2028, Institute for Energy Economics and Financial Analysis

Latest articles

Burckhardt Compression announces leadership change in Services Division

Ad hoc announcement pursuant to Art. 53 LR

January 12, 2026