The global push for decarbonization has placed hydrogen firmly in the spotlight. As a clean and versatile energy vector, it holds the potential to power heavy industry, fuel transport, and store energy free from greenhouse gas emissions during periods of low solar or wind output. Hydrogen can be produced in different ways. To understand its potential, we must first understand how it is made and what it costs to produce.

The industry often uses a color spectrum to classify hydrogen based on its production method and associated carbon footprint. Navigating this spectrum is the first step for any organization looking to invest in or adopt hydrogen technologies. “The hydrogen economy” series will dive into the different hydrogen production processes and analyze the levelized costs of hydrogen (LCOH) that determine the commercial viability of each pathway.

Green hydrogen

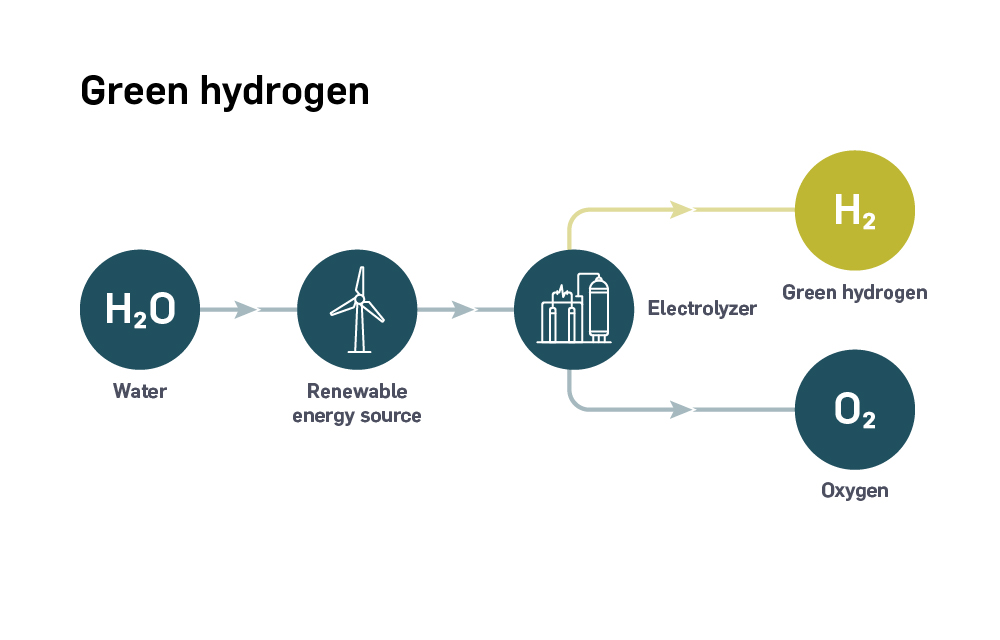

Green hydrogen is produced through water electrolysis, a process that uses electricity to split water (H2O) into hydrogen (H2) and oxygen (O2). When powered by renewable sources like wind or solar, the entire process is virtually free of greenhouse gas emissions.

The cost of production: Green hydrogen

The cost of green hydrogen is overwhelmingly dependent on the availability of large scale renewable electrical power generation, the cost of electricity and access to sufficient quantities fresh water.

Electrolysis is energy-intensive, requiring approximately ~45-60 kWh of electricity to produce a single kilogram of hydrogen. As the table below illustrates, this creates a direct correlation between electricity prices and the minimum costs of hydrogen, even before capital and operational expenditures are considered (CAPEX / OPEX).

Advantages

- The production of green hydrogen does not generate carbon emissions.

- In regions with excessive renewable energy, green hydrogen production can absorb excess capacity - effectively storing surplus energy that would otherwise go unused, provided the electrolyzer plant operates with sufficient full load hours.

Disadvantages

- Its high electricity consumption makes it commercially viable only in regions with abundant and low-cost renewable energy.

- Water electrolysis is potentially competing with scarce freshwater resources.

Grey and blue hydrogen

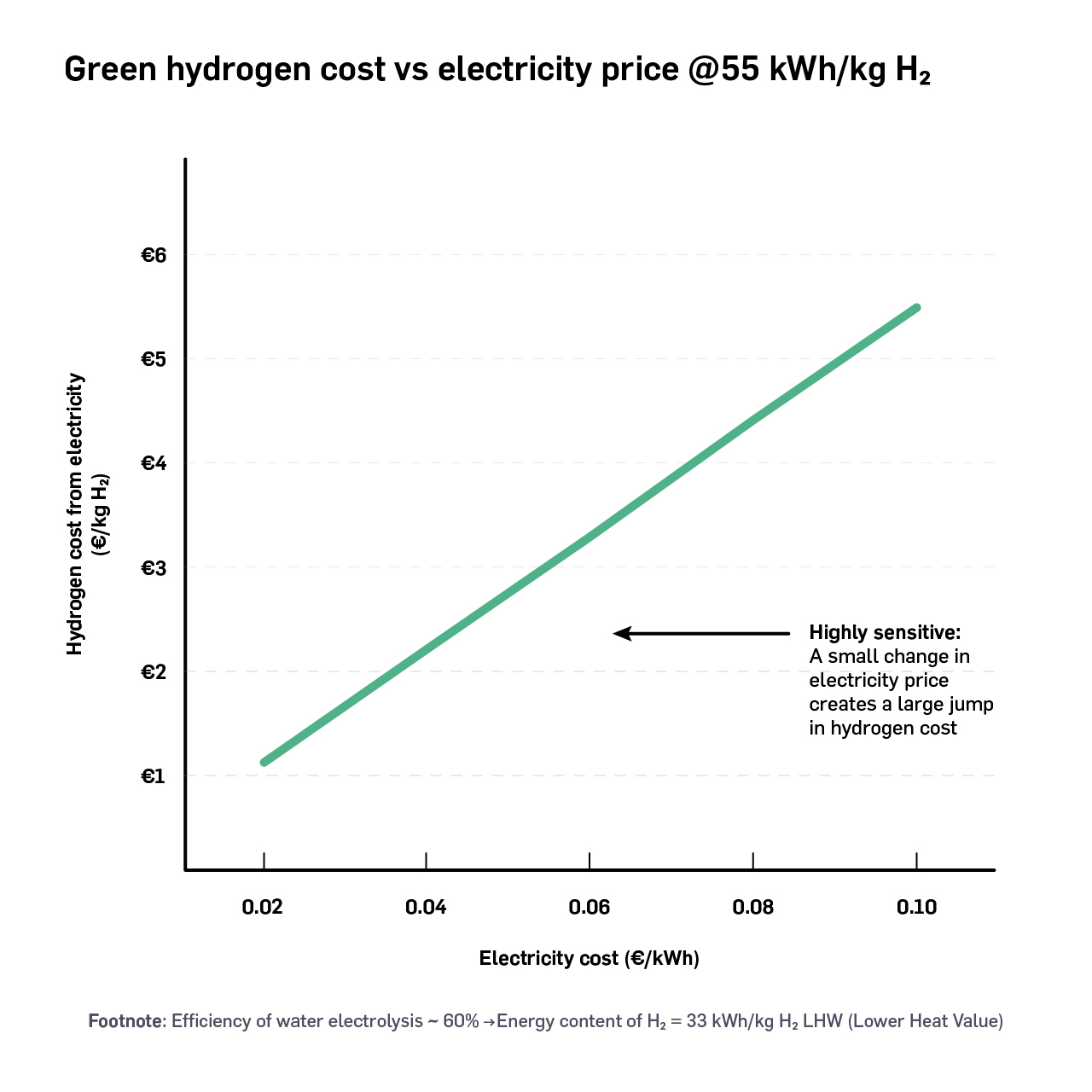

Today, the vast majority of the world's hydrogen is produced via steam methane reforming (SMR). In this mature process, methane (CH4 - the main component of natural gas) reacts with steam to produce hydrogen and carbon dioxide (CO2) as a byproduct. Grey hydrogen refers to hydrogen production where CO2 is released into the atmosphere, contributing to global warming.

Blue hydrogen is an evolution of this process. It uses the same SMR method but incorporates Carbon Capture, Utilization, and Storage (CCUS) technology to capture the CO2 emissions before they are released.

The cost of production: Blue hydrogen

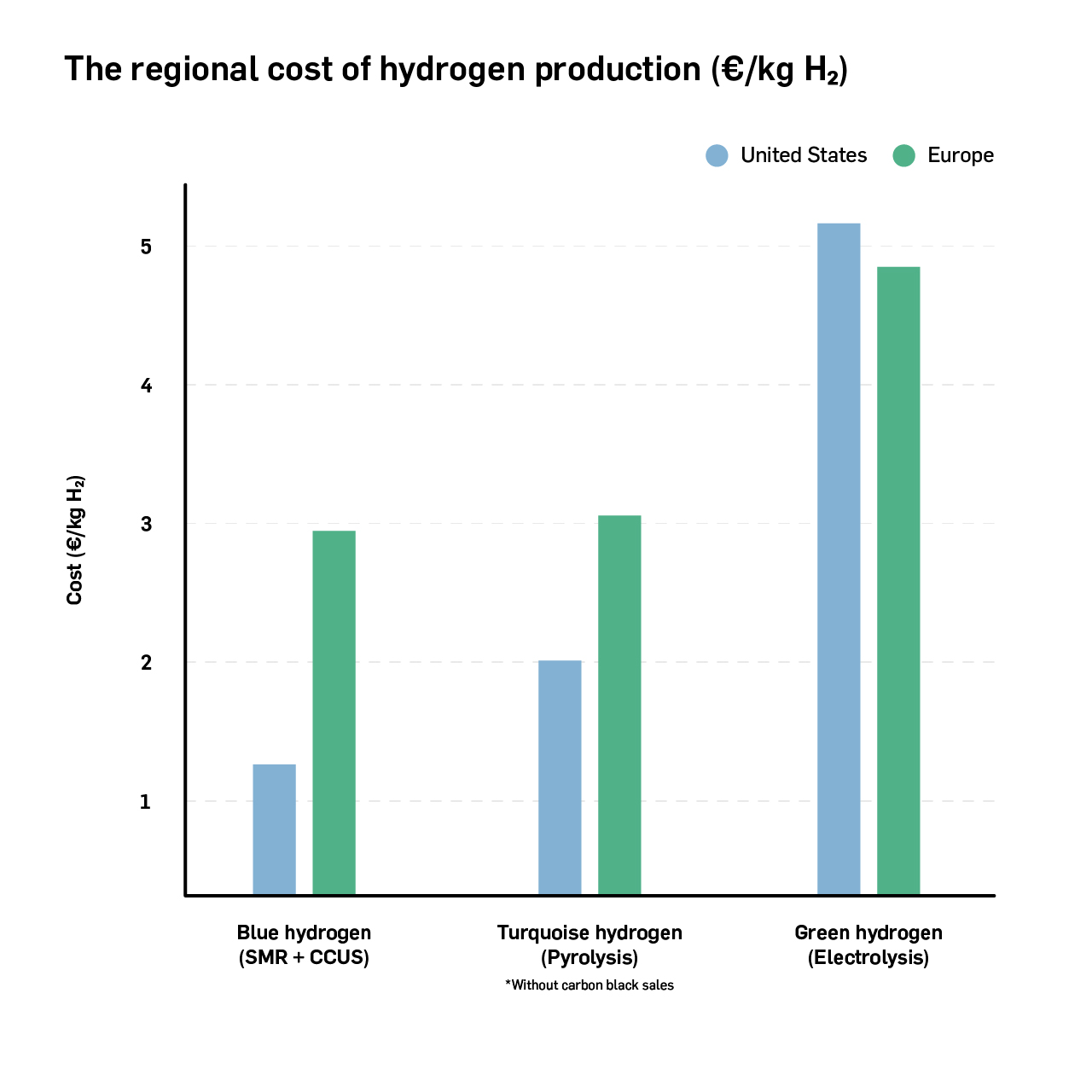

For blue hydrogen, the key cost drivers are the price of natural gas and the costs of carbon capture, transportation, and storage.

| Metric | United States | Europe |

|---|---|---|

| Methane cost basis | $4 / mmBTU (e.g. Henry hub) | €32.92 / MWh (e.g. TTF) |

| Carbon capture and storage costs | €33 / ton H2 | €33 / ton H2 |

| Total estimated hydrogen cost | ~ €1.26 / kg H2 | ~ €2.97 / kg H2 |

The lowest estimated cost for carbon capture and storage (CCUS) is approximately 33 EUR per ton of CO2, which translates to 0.33 EUR per kilogram of hydrogen (based on 10 kg of CO2 per kg of H2 at 33 EUR/t CO2).

However, CO2 storage sites are often not located near SMR production facilities. The logistics involved; CO2 liquefaction, transport by train or ship or pipeline, and injection into storage, can significantly increase overall costs. Therefore, the implementation of blue hydrogen as a low-carbon energy vector certainly develops first in regions where SMR facilities are located near suitable CO2 storage sites, ensuring both economic and logistical viability.

Advantages

- Blue hydrogen is a low-carbon energy option that can be produced at scale today by leveraging existing natural gas infrastructure. It is one cornerstone of low emission energy supply while renewable energy capacity and green hydrogen production continue to expand.

- When biogenic feedstock is used in SMR, the combination of SMR and CCUS can potentially result in a near below zero CO2 footprint.

Disadvantages

- Blue hydrogen still relies on fossil fuels, and carbon capture technologies are typically not 100% efficient, meaning some emissions persist.

- Its cost-competitiveness is highly sensitive to volatile natural gas prices and carbon tax policies.

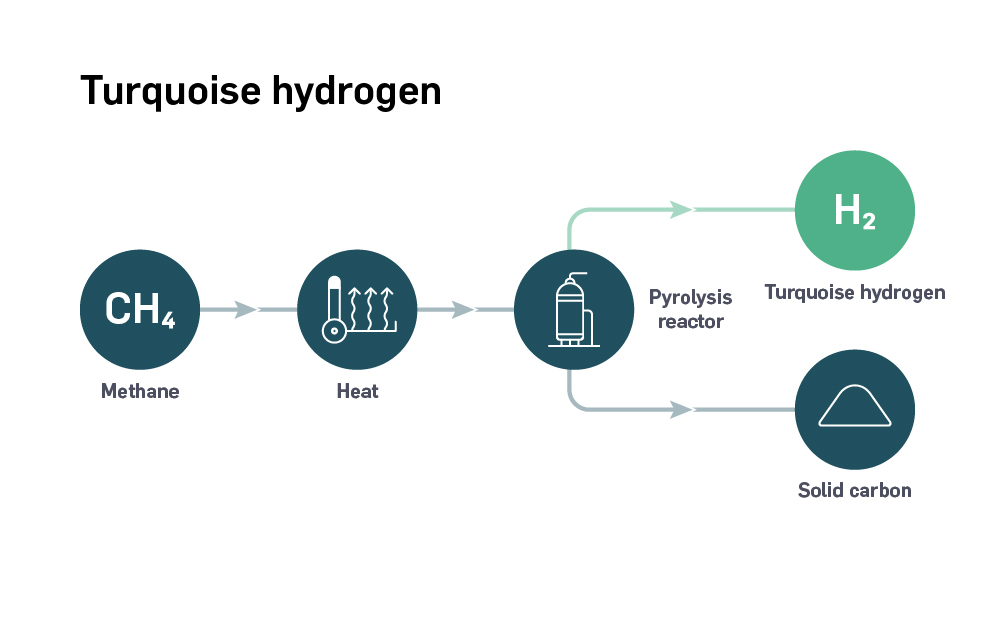

Turquoise hydrogen

A promising new pathway is turquoise hydrogen. Produced through methane pyrolysis, this process heats methane in the absence of oxygen, splitting it into hydrogen gas and solid carbon (carbon black) that can be marketed to several industries.

The cost of production: Turquoise hydrogen

This method offers a different economic model. It requires significantly less energy than electrolysis (~10-15 kWh/kg H2) and avoids producing gaseous CO2, thus avoiding high carbon penalties. Furthermore, it creates solid carbon black, a valuable commodity that can generate an additional revenue stream as it can be used in manufacturing tires, coatings, and electronics. Feedstock cost remains the primary driver.

| Metric | United States | Europe |

|---|---|---|

| Methane cost basis | $4/mmBTU (e.g. Henry hub) | €32.92 / MWh (e.g. TTF) |

| Renewable energy costs | ~ €1.08 / kg H2

| ~ €0,96 / kg H2

|

| Total estimated hydrogen cost (incl. CAPEX & OPEX) | €2.00 / kg H2 | €3.10 / kg H2 |

Advantages

- This innovative method avoids direct CO2 emissions during production by pre-combustion removal of the carbon.

- Unlike electrolysis, methane pyrolysis does not require water, making it suitable for regions with limited freshwater resources.

- The solid carbon byproduct (carbon black) can be sold, potentially contributing to the revenue stream of pyrolysis plant operators.

- If the methane feedstock is biogenic, the methane pyrolysis contributes with a negative CO2 footprint.

- Methane pyrolysis consumes significantly less green energy compared to water electrolysis.

Disadvantages

- The technology is still maturing and has not yet reached the industrial scale of SMR or electrolysis.

- The commercial success depends a lot on the volatile cost of methane.

The final cost comparison: Europe and the United States

The graph below displays the cost of producing three types of hydrogen: green, blue and turquoise hydrogen in Europe and in the United States.

Unlock your hydrogen applications with our advanced solutions

While the color of hydrogen determines its carbon footprint and feedstock, its physical properties remain consistent across production methods. Whether it is produced via electrolysis, SMR, or pyrolysis, the next step in conditioning the hydrogen for downstream use is compression. This initial pressurization is the gateway to the entire hydrogen value chain, where it is compressed to high pressures for efficient storage, transport, and delivery to the end-user.

As the hydrogen economy scales, safe and efficient compression technology will be the backbone that enables its growth, minimizing operational costs and maximizing the profitability of hydrogen projects worldwide.

To learn more, visit our webpage below, where we showcase key applications in which our expertise and engineered solutions support efficient, reliable, and scalable hydrogen mobility and energy systems.

Next in "The hydrogen economy" series

In our next article, we will move beyond hydrogen production cost to explore the key success factors such as water availability, energy infrastructure, and policy, that determine which color of hydrogen is truly the right strategic choice for a specific location.

Latest articles

Burckhardt Compression announces leadership change in Services Division

Ad hoc announcement pursuant to Art. 53 LR

January 12, 2026