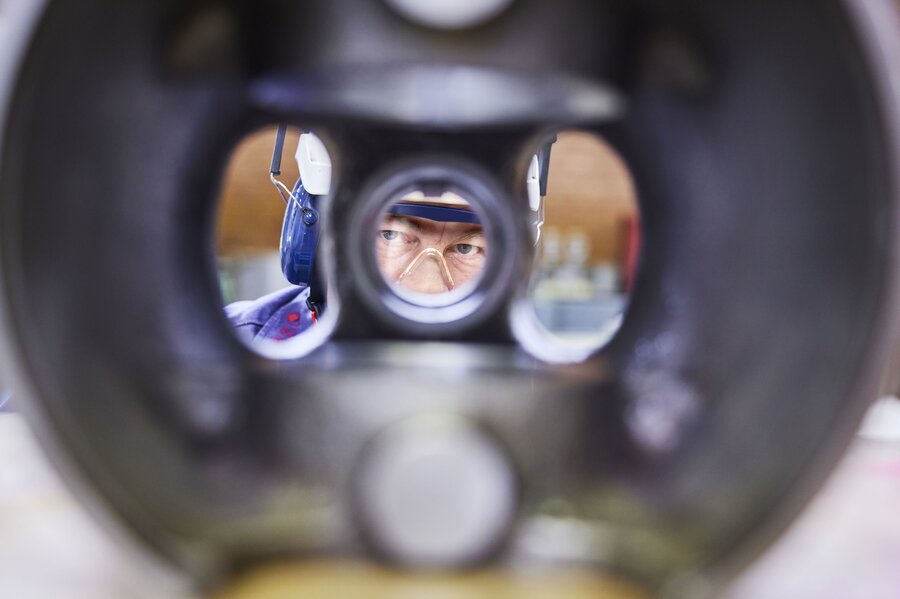

Petrochemical plant boosts compressor efficiency with expert guidance

Burckhardt Compression (US) has successfully completed an 8‘000-hour overhaul on two Laby® compressors and provided guidance to a leading petrochemical company on essential parts to stock for maintaining operational efficiency. A major global energy company, operating a petrochemical plant in Western Pennsylvania, required the first regular service for its two Burckhardt Compression Laby® compressors.

These compressors are integral to the plant’s process of producing plastic pellets. Although the plant began operations two years ago, the compressors were purchased over four years ago. The plant reached out to our team not only for prompt and professional service but also for expert advice on critical parts to stock. We assist our customers with stock recommendations to ensure optimal operation and offer frame agreements for spare parts. Our primary focus is on supporting our customers to achieve operational efficiency,

maximum productivity, and the lowest lifecycle costs.

The team at Burckhardt Compression was exceptional. You proactively reached out to us and were there when we were ready to overhaul the compressors. Your support was critical to ensuring minimum downtime and maximum productivity.

What our customer says

Customer challenges

- No maintenance performed since installation

- Quick service needed to minimize downtime

- Expertise required with involvement from sales and project managers, field service technicians, and mechanics

- Critical spare parts required urgently, with no spares or special tools currently in stock

- Advice needed on maintenance service schedules

Technical data

| Manufacturer | Burckhardt Compression |

|---|---|

| Type | 4D375B-2B_1 |

| Power | 1'500 kW / 2'010 hp |

| Speed | 356 rpm |

| Gas | Hydrocarbons |

| Suction pressure | 1.09 bara / 15.81 psia |

| Discharge pressure | 13.80 bara / 200.15 psia |

Our solution

Consistently stayed the course

Since the Laby® compressors were purchased some time ago, our sales and technical teams stayed tuned for the required service, adhering to our values of responsibility and performance. They proactively reached out to the plant and were prepared to act swiftly whenever and wherever the plant needed our assistance.

Expert knowledge

In the spirit of true partnership, our team of sales professionals, field service technicians, and experienced mechanics provided expert guidance on which critical spare parts and special tools for overhauls need to be kept in stock.

High-quality and quick turnaround

Adhering to highest quality standards, our team ensured the customer received optimal service with a quick turnaround.

Customer benefits

- Reliable partnership for future projects with expert knowledge and guidance

- Team of experts available to provide quick, professional, and local service

- Sensible stock of critical spare parts and special tools on hand for flawless future service interventions saving time and money

Latest articles

Burckhardt Compression announces leadership change in Services Division

Ad hoc announcement pursuant to Art. 53 LR

January 12, 2026