Laby® 2K70

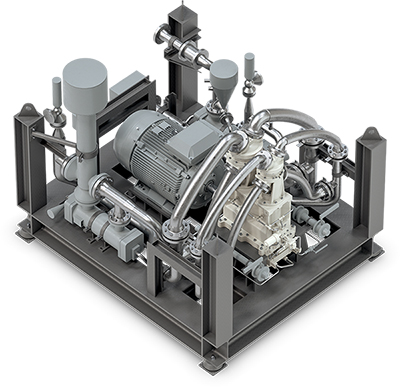

Laby® Compressor 2K70 for Low-Pressure Marine Applications

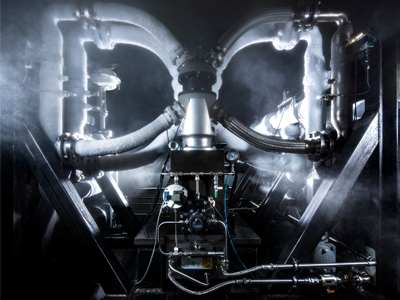

As the cryogenic LNG evaporates when it warms up within the vessel tanks, the occurring boil-off gas needs to be compressed. Subsequently, the compressed gas can be used as fuel for the WinGD X-DF 2-stroke propulsion engines on board. Burckhardt Compression’s unique 2K70 Laby® BOG compressor system handles relatively small mass flows at cryogenic gas temperatures, without the need for BOG pre-heating. It is specifically designed for marine applications, offering high efficiency, compact design, low complexity, and easy maintenance.

Customer Benefits

Design

- Applicable for all common cargo tank solutions

- IMO type C (pressurized)

- IMO type B

- Membrane type

Innovation

- Re-definition of proven Laby® K-type concept

- High-speed -> compact design

- Vibration isolation

- Higher efficiency through flow optimization

- Standard materials, marine rules conform

- Usage of modern manufacturing technologies (3D printing)

Cost Efficiency

Saving CAPEX

- Standardized product

- Compact arrangement – small footprint

- Cryogenic design – no BOG pre-heater required

Saving OPEX

- Minimized coolant consumption

- no extra costs for special lubricants

- no costs for oil removal system

- Higher efficiency, lower shaft power consumption

Easy Operation and Maintenance

Operational aspects

- Low system complexity

- Oil-free Laby® design: no risk of oil carry-over

- Gas-tight – no loss of cargo, no need for purge/buffer gas

- AVM mounted, flexible hoses – no rigid connections to ship foundation and piping system

Maintenance aspects

- Onboard maintenance possible

- Low number of wear parts

- Simple design – easy maintenance for ship crew

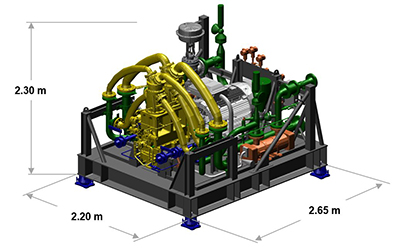

Technical Data

| 2K70-A | 2K70-B | ||

| Tank type | Membrane | IMO type C (pressurized), IMO type B | |

| Gas | CH4 (max. 10% N2) | CH4 (max. 10% N2) | |

| Capacity kg/h | max. 1000 * | max. 500 ** | |

| Speed rpm | 900 – 1800 | 900 – 1800 | |

| Stroke mm | 70 | 70>/td> | |

| Average piston speed m/s | 2.1 – 4.2 | 2.1 – 4.2 | |

| Pin load kN | max. 35 | max. 35 | |

| Shaft power kW | max. 110 | max. 110 | |

| Crankcase type | Gas-tight up to 15 bar g | Gas-tight up to 15 bar g | |

| 1st stage | Piston diameter mm | 250 | 160 |

| Suction pressure bar g | 0.0 – 0.5 | 0.5 – 4.0 | |

| Discharge pressure bar g | 2.5 – 5.0 | 3.5 – 11.5 | |

| 2nd stage | Piston diameter mm | 160 | 160 (single acting) |

| Discharge pressure | 8.0 – 16.0 | 8.0 – 16.0 |

* at nmax, psmax, pdmax, MWT 17.2 ** at nmax, psmax, pdmax, MWT 17.2

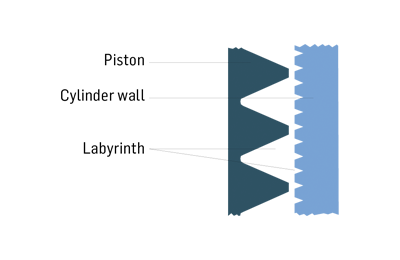

Labyrinth Sealing Technology

The unique technology is applied between the piston and the cylinder wall and between the piston rod gland and the piston rod. The labyrinth sealing effect is created by numerous tiny throttling points. At each of these throttling points, pressure energy is transformed into kinetic energy as a result of the flow restriction.

Marine Service Offering

What you need, when and where you need it. Our dedicated marine team offers comprehensive solutions to maximize the performance of your compressor systems based on a thorough understanding of your needs / business.