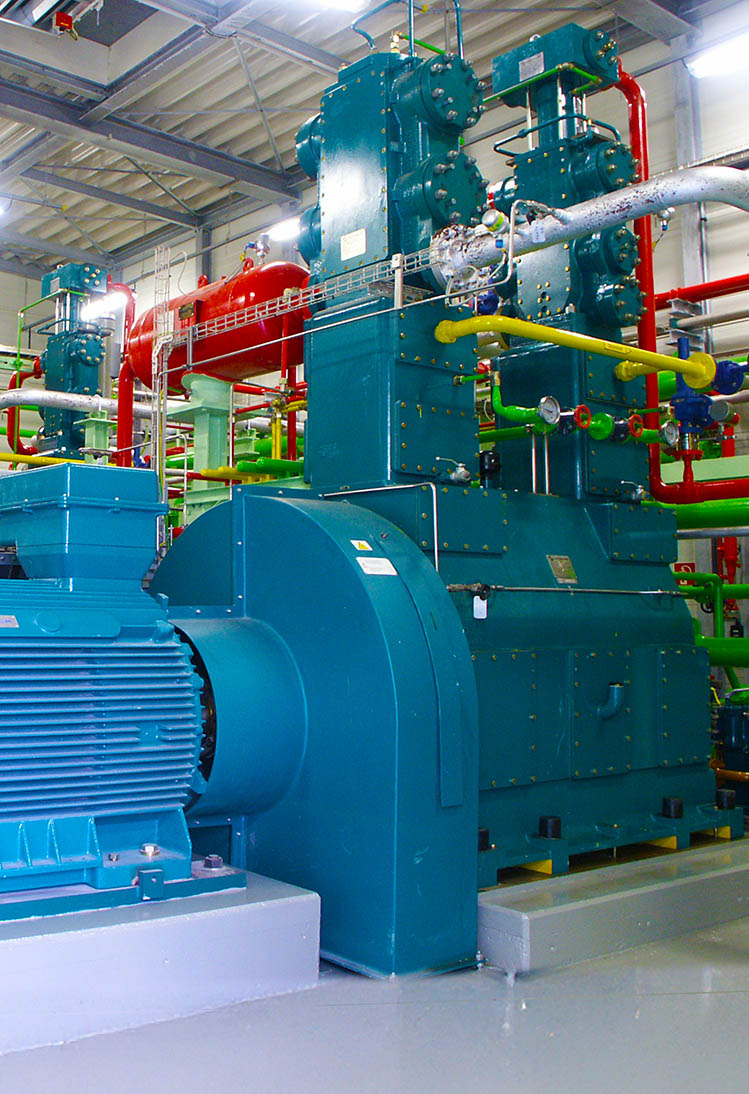

Hydrogen trailer filling compressors with 24 years’ reliable service and counting

For over 24 years, Burckhardt Compression and Infraserv Höchst in Germany have maintained a strong and enduring partnership. This collaboration began with the delivery of two hydrogen compressors for a trailer filling application at Infraserv’s Frankfurt site. A key requirement for the system was a mean time between overhauls (MTBO) of 8‘000 hours to ensure maximum availability. These high-pressure, dry-running compressors have been performing one of the site’s most demanding tasks. Despite the challenging conditions, they have consistently delivered reliable and efficient performance - hardly any unplanned intervention has been required. This impressive performance is also a testament to Burckhardt Compression’s more than 60 years of experience in servicing hydrogen compressors.

From the outset, the close relationship between the operator and Burckhardt Compression laid the foundations for a lasting partnership that would supply all the necessary technical expertise and support. This has included integrating new sealing materials and designs as they have evolved and managing a program of continuous improvement. Burckhardt Compression’s local service presence in Germany provides ongoing support for the two hydrogen compressors as well as numerous Laby® Compressors for other applications.

“Over the past few years, we’ve experienced an almost entirely trouble-free operation – with minimal unplanned maintenance and hardly any unexpected downtime. This has enabled us to ensure optimal productivity for our company. The continuous support from Burckhardt Compression has been invaluable, ensuring our equipment performs faultlessly. The hydrogen trailer filling process is a key element of our operations and availability is essential.”

Steffen Enghard, Betriebstechnik Mechanik, Infraserv Höchst

Customer targets

- Low operational costs

- Maximize compressor availability

- Fast technical and field service support

- Continuous operator and maintenance training

Technical data

| Manufacturer | Burckhardt Compression |

|---|---|

| Type | Process Gas Compressors 2CS |

| Power | 250 kW / 348 hp |

| Speed | 420 rpm |

| Gas | Hydrogen |

| Suction pressure | 5 barg / 72 psig |

| Discharge pressure | 230 barg / 3'335 psig |

| Lubrication | Dry-running |

Our solution

Outstanding compressor design and components

The compressors’ design, along with the carefully selected components and sealing materials, has ensured long-term reliability and efficiency. For wear parts, in-house developed and manufactured Persisto® materials are used along with the Redura® sealing system designs. These key components are continuously tested on the in-house high-pressure, oil-free piston compressor to meet the hightest standards.

Partnership solution

A dedicated single point of contact with in-depth knowledge of the asset has worked closely on-site with the local operations team. This setup has ensured clear, consistent communication and has enabled efficient planning and execution of all site interventions.

Strong local presence and 24/7 technical support

With sites in Bremen, Neuss, Rheine and Flensburg, Burckhardt Compression maintains a dense service network in Germany, but also across the globe - supported by 24/7 availability and a team of highly skilled technicians. This strong local presence is part of our broader global footprint, enabling us to deliver expert support worldwide.

Compressor training for on-site team

Tailored training sessions were provided to the customer’s on-site maintenance team, equipping them with the expertise required for the safe and efficient operation of high-pressure reciprocating compressors.

Customer benefits

- Cradle-to-grave support

- Total cost of ownership (TCO) has been minimized

- Excellent compressor availability and uptime

- Fullfill the 8’000-9’000 hours MTBO with regular start/stops

- Up to 12’000 hours MTBO can be achieved

- Swift response times and local OEM expert support whenever needed

- Trusted partnership through deep mutual understanding

Latest articles

Burckhardt Compression announces leadership change in Services Division

Ad hoc announcement pursuant to Art. 53 LR

January 12, 2026