21. November 2017 | Raffinerie, Prozessgas-Kompressor, Europa, Success Story

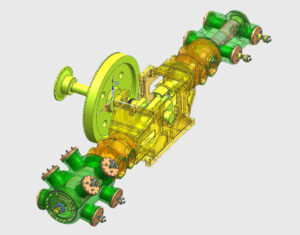

Major Modernization of Gas Lift Compressor

A production increase and a higher system availability was requested. Burckhardt Compression took on the challenge and conducted a thorough inspection in order to issue recommendations; always with the goal to keep cost and delivery time down and reliability up!

Customer Challenge:

- Upstream production increase requested a third gas lift compressor and a higher system availability (only two out of three existing compressors were in operation).

- Due to severe cylinder damage, the third compressor has been unavailable for several years. A major modernization was required.

- Additional risks due to the high concentration of H₂S (hydrogen sulfide) and hydrocarbon gases

Application Description:

| Type | Other brand process gas compressor | Gas | Hydrogen sulfide, methane |

| Power | 709 kW / 950 hp | Suction pressure

Discharge pressure |

4 bara / 58 psia

57 bara / 826 psia |

| Speed | 375 rpm | Lubrication | Lube |

Burckhardt Compression Solution:

- Thorough inspection of the compressor and recommendation for improvements

- Reverse engineering and redesign without having the old parts or original drawings available, including the implementation of the latest technology

- Repair of several main components and upgrade to the latest technology

- New state-of-the-art Burckhardt Compression key components:

Redura® Sealing Systems and Burckhardt Poppet Valve™

Customer Benefits:

- 40% lower investment costs and faster delivery time compared to a new compressor solution

- Increased reliability of compressor components by applying improved in-house developed material, resistant against H₂S contamination

- Higher availability of compressor capacity for higher flow needs

- No modifications of the foundation needed