8. Juli 2012 | Petro-/Chemische Industrie, Success Story, Hyper-Kompressor, Asien

Upgrade of HP Cartridge for Hyper Compressor

A hyper compressor in an Ethylene plant experienced issues with the high-pressure cartridge. The customer involved Burckhardt Compression to analyze the situation and to make suggestions for improvement and to increase reliability.

Customer Challenges:

- Increase reliability of high-pressure cartridge

- Simplify installation procedure of high-pressure cartridge for lower downtime during service interval

- Material analysis and propose possible improvements

Application Description:

| Type | Other brand hyper / secondary compressor | Gas | Ethylene |

| Power | 21’400 kW / 27’700 hp | Suction pressure

Dircharge pressure |

268 / 1’742 barg

1’742 / 3’100 barg |

| Speed | 214 rpm | Lubrication | Forced lubrication to cylinder |

Burckhardt Compression Solution:

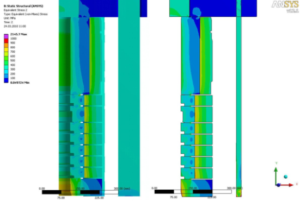

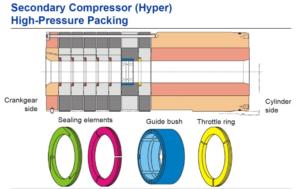

- Finite element analysis (FEA) of high-pressure cartridge

- Indicating improvements for high performance material to be used

- Know-how and experience provided from the market leader in LDPE compressor design

- Upgrade high pressure cartridge to Burckhardt Compression HyproPack™ design