June 06, 2023 | News

Hydrogen – the fuel of the future

Green hydrogen has a key role to play in the energy transition. As part of this shift, Burckhardt Compression's leading compression solutions are used throughout the hydrogen value chain.

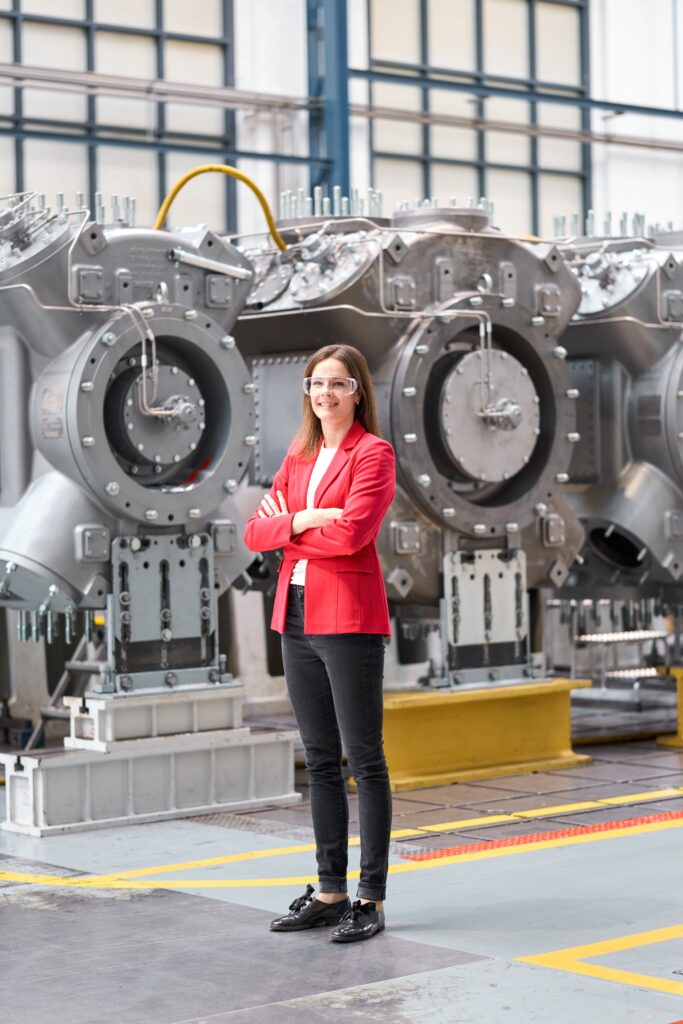

5 questions to Veronika Schelling, Hydrogen Mobility & Energy Leader

Hydrogen has long been called the “fuel of the future”. Is it currently having its breakthrough moment?

Yes, it has clearly taken off in the past 18 months. The Biden administration’s Inflation Reduction Act (IRA) and the EU’s Delegation Act (DA), passed in February 2023, have now set out clear stipulations and definitions, including for significant subsidies. Green hydrogen has a key role to play in the energy transition that reaching our climate goals entails. Green hydrogen refers to hydrogen that is produced by electrolysis using electricity from renewable sources. In other words, hydrogen that’s climate-neutral.

Where do you think there is scope for using green hydrogen?

In my view, the public debate is focused too much on mobility, especially on whether hydrogen can replace fossil fuels for cars. What most people forget is that industrial enterprises need huge amounts of clean energy. Environmental legislation means that firms producing steel, glass or fertilizer, in particular, need to substantially reduce their CO2 emissions. In the future, industrial enterprises will need large quantities of climate-neutral energy and will likely use around half of the green hydrogen that’s produced.

How important is hydrogen for Burckhardt Compression?

We focus on the contruction and use of compression systems, which are deployed throughout the entire hydrogen value chain. Here’s an example: We recently provided a large Swiss energy supplier with a compressor system for a plant to produce hydrogen from hydro power. These systems can also be supplied to gas stations, for instance: Refueling calls for very high level of pressure – another field where our compressors can be used. Generally, hydrogen is produced far away from the place where it’s needed, meaning that there’s no option but to transport it. Hydrogen is a very lightweight gas, so you need a certain level of pressure to do so. As a result, compressors are indispensable due to the very nature of the task at hand. We’ve ramped up our research and development, over the past few years, and thanks to this, our system solutions are unique in the market.

“Today, the requirements are emerging in the hydrogen economy and customers require a strong technical partner. Our commitment is to offer our customers reliable end-to-end compression solutions.”

Veronika Schelling, Hydrogen Mobility & Energy Leader

What does the Hydrogen Mobility & Energy (HME) team do?

Our company’s goal is for at least 40% of our compressor solutions to be used in systems supporting the energy transition by 2027. Consequently, the core tasks of the HME team include identifying trends and the latest needs. As an interdisciplinary team, we work across departments. This sees us collaborate with the sales and technical teams, including in research and development and project engineering and management. We jointly define the requirements and potential applications, weighing them against the resources needed to put them into practice. Our collaboration with suitable partners represents another key element: We’re able to add value to them thanks to our extensive expertise and global service capacities.

What trends are you seeing in the hydrogen sector?

Today, the requirements are emerging in the hydrogen economy and customers require a strong technical partner. Projects are getting more complex – and time frames are more condensed. One thing that hasn’t changed is our commitment to offering our customers reliable end-to-end solutions over the lifetime of their facility. That’s why we’re integrating service aspects to a greater extent from the get-go. They include preventative maintenance, based on remote system monitoring and diagnosis. Finally, we see that the hydrogen production facilities and fuel stations are getting larger, which is essential for reaping the benefits of scale and for enabling green hydrogen to become cost competitive with other alternatives.