Polyolefin Production

Labyrinth Type Reciprocating Compressors in Polyolefin Applications

2 Years of Uninterrupted Operation

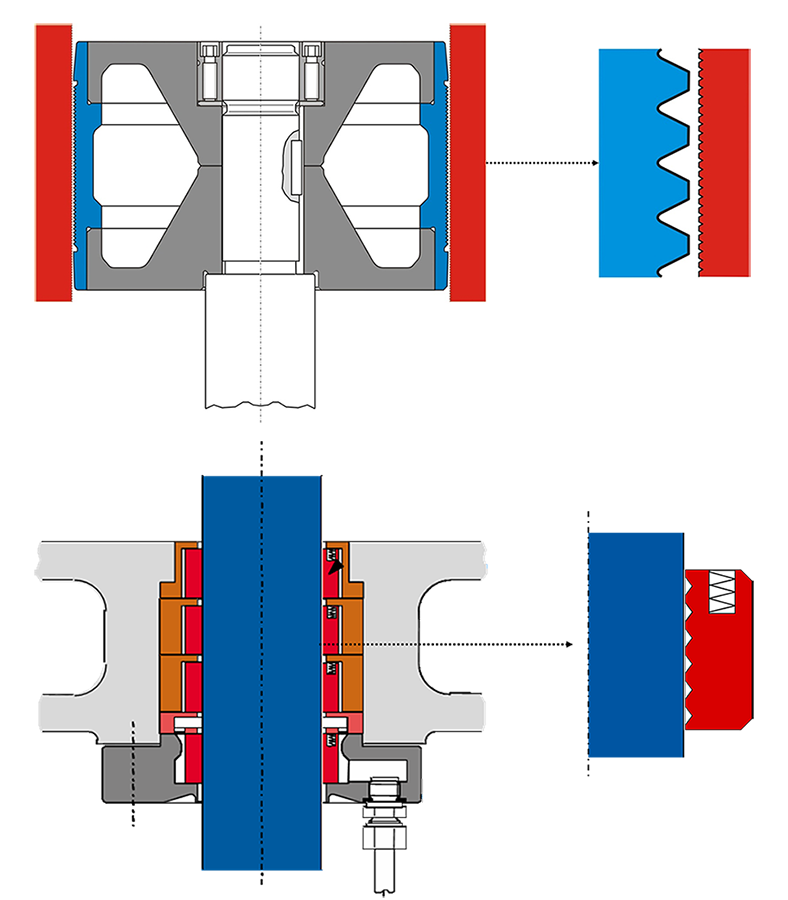

- No friction due to no contact between cylinder wall and piston.

- No friction due to no contact between piston rod and piston rod gland.

- The labyrinth seals (piston skirt and piston rod gland) will not wear even with particle contaminated process gases.

- Due to the absence of friction, hot spots will be avoided. This reduces the risk of polymerization inside the compression chamber.

- Due to the absence of plastic piston rings, the likelihood of unplanned shut downs is minimized

Your Benefit

~USD 4.5 Mio increased profit compared to non-lube piston compressors due to lower down time when using a Laby® compressor.

(*) Reference project: 280 kta average estimation with PP market selling price of 1’100 USD/ton. Maintenance time reduction of 5 days every 2 two years.

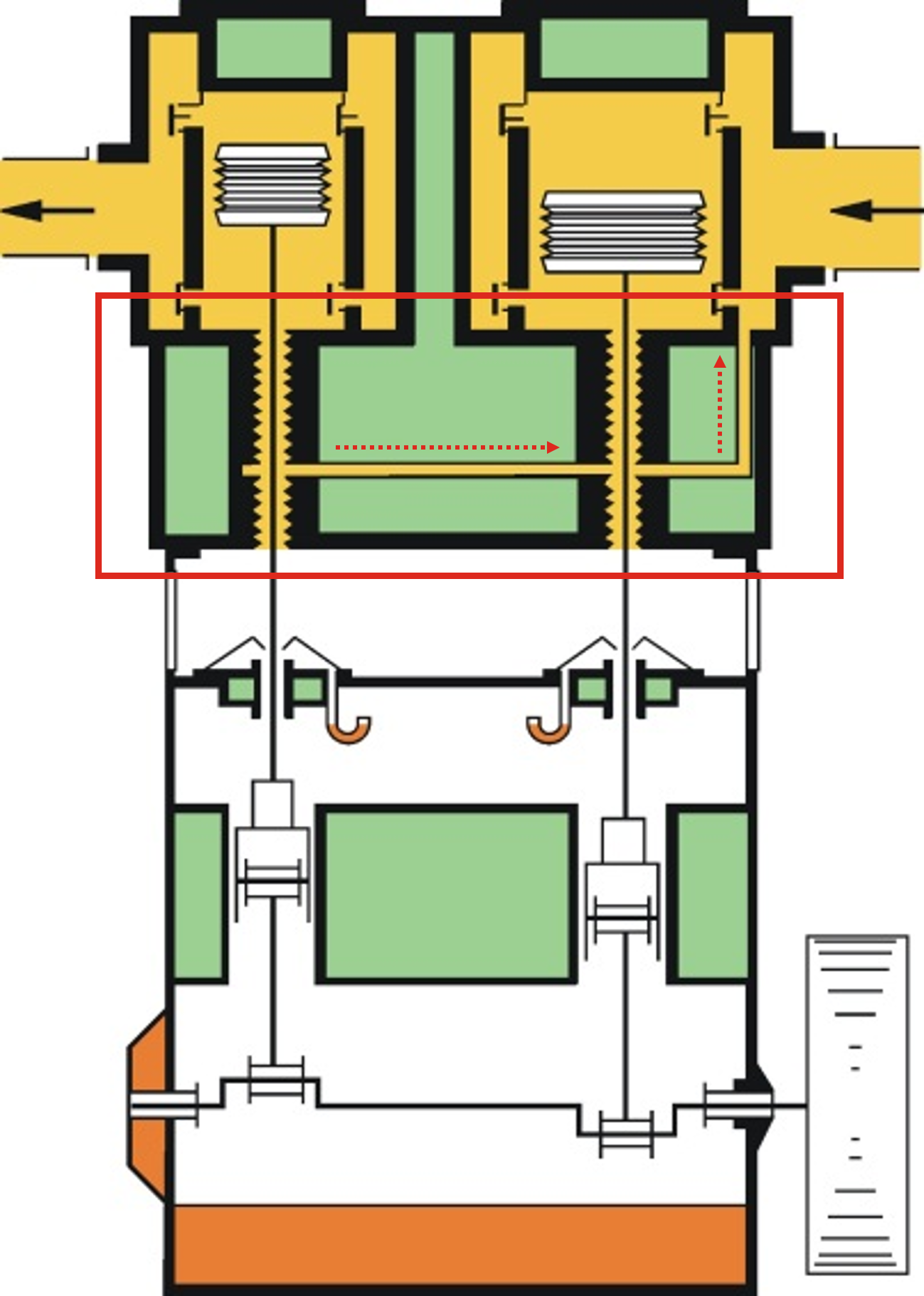

No Waste of Process Gas

- Gas tight frame design prevents waste of leak gas

- Laby® Compressors are equipped with leak lines on the piston rod glands sending any leak gas back to compressor suction side.

Your Benefit

Piston rod packing leakage rates on a traditional Non-Lube piston ring compressor are up to 0.3% of total gas capacity. In this case the leakage is flared. The amount of wasted process gas can be between 500 – 850 kg/day depending on plant size and process.

The Laby® compressor provides a saving of 150’000 USD to 250’000 USD per year by not sending any leakage gas to the flare.

(*) Average estimation with feed stock price of 800 USD/Ton

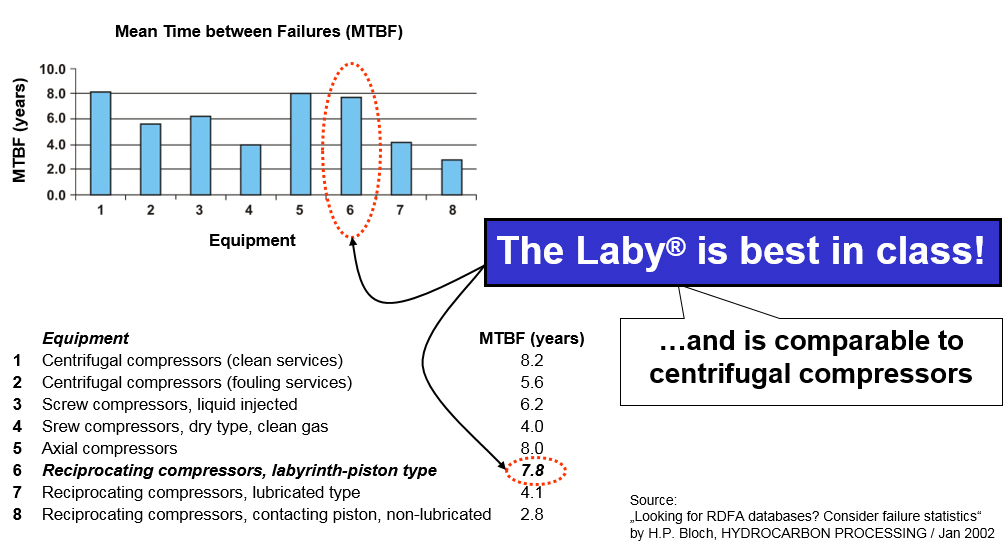

Reliability of Production

Your Benefit

Laby® compressor provides highest plant reliability, protecting the end-user in contractual obligations toward its own customers.

The Laby® compressor is almost 3 times more reliable compared to an non-lube piston ring compressor. It enables the end-user to deploy only one Laby® compressor vs the traditional one running and one stand-by scenario.

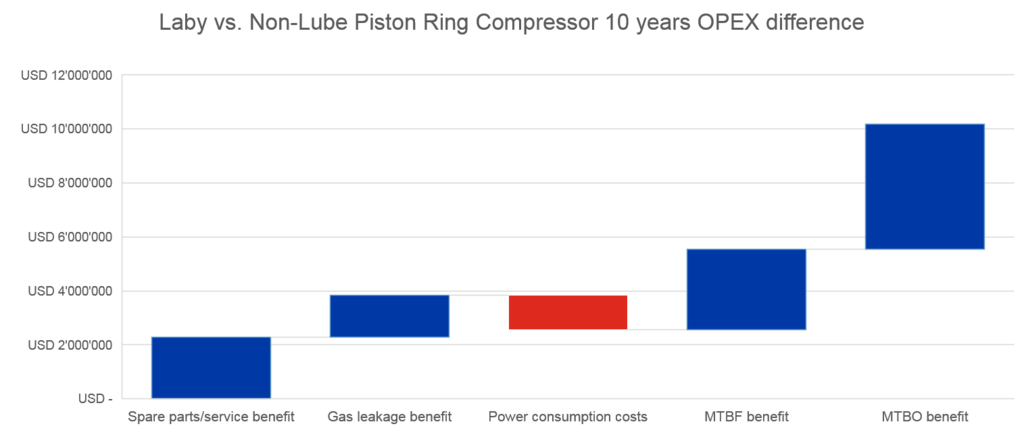

10 Year OPEX Advantage Summary

Your Benefit

Despite the slightly higher power consumption one Laby® compressor compared to one non-lube piston ring compressor displays an OPEX benefit of USD 10 Mio. over 10 years of operation.

In-House Capabilities

- Specific sizing & layout of the right equipment for efficient operation of the compressor system and therewith the entire plant

- Outstanding project management and engineering expertise including: compressor design & selection of material, piston rod packing operation modeling, performance calculations, full load cycle analysis, valve dynamics analysis, pulsation & vibration analysis, torsional analysis and drive train design, 3D modeling, thermal design for heat exchangers

- Full compliance with various standards

- Instrumentation, control & monitoring

- Transportation & installation

Your Benefit

Burckhardt Compression has all the expertise and know-how needed, in order to offer a smooth project execution.

Worldwide Network to Ensure Close Contact to all Clients

- Burckhardt Compression is the inventor of the labyrinth compressor technology – first Laby® Compressor was installed in 1935.

- High number of references for different applications worldwide.

- Close contact with major licensors for polymer production processes.

- Extensive global service capabilities with service centers all over the world.

Your Benefit

Our compression specialists are ready to share their profound knowledge and experience in order to support you with the best possible products and services for your project.