Laby®-GI Compressors

Laby®-GI Compressors – Fully Balanced Reciprocating Compressor with Highest Operational Flexibility

Through detailed cooperation with recognized marine equipment and system suppliers, and the close relationship to well known end-users in the offshore market, Burckhardt Compression has developed the Laby®-GI, a highly unique and flexible compressor solution that perfectly fits a wide range of individual customer requirements for highly demanding offshore applications.

Traditional engineering and our decades of experience are the foundation of the vertical, in-line, 6-crank, low speed reciprocating compressor. The innovative design results in a unique but highly effective, fully balanced machinery configuration.

Markets and Applications

Click on a market to switch, or continue with Laby®-GI Compressor

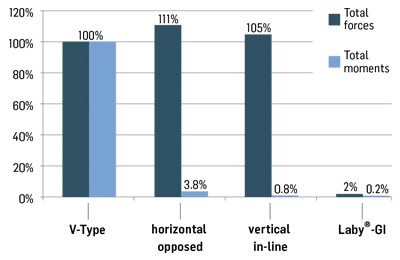

100% Mass Balancing

50x less total forces and 5x less free moments

The fully balanced crankgear leads to a smooth running compressor. The compressor will not stimulate the connected offshore structure or interfere with the structural analysis of the naval architecture. Vice versa neither roll or pitch nor engine vibration, for example on a LNG carrier, will have the slightest influence on the compressor system and its auxiliaries.

Resulting benefits

- no free forces and moments

- no influence on supporting offshore structure

Unique Cylinder Sealing System

Depending on the compression duty pressure and temperature requirements, we can offer either lubricated or non-lubricated cylinder sealing, allowing the selection of the very best technology according to individual stage process requirements. With the Laby®-GI Compressor we can provide a wide range of cylinder configurations and combinations to best fit your specifications.

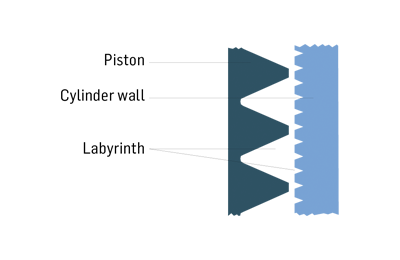

Labyrinth sealing

In the piston and piston rod gland many tiny throttling points create a friction-less sealing effect. The avoidance of mechanical friction and the contactless cylinder results in an extremely long lifetime of sealing components with unmatched reliability and availability.

Resulting benefits

- no mechanical wear due to contactless seals

- for cryogenic gas suction temperatures without pre-heating of the gas nor pre-cooling of the compressor

- for oil-free compression

- for longest lifetime

- very low maintenance costs

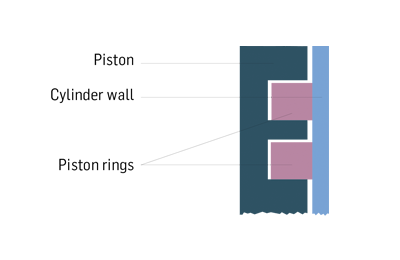

Ring sealing system

These conventional sealing systems are successfully applied in a wide range of applications. The vertical alignment of the Laby®-GI Compressor provides low wear of the sealing and guiding elements on the piston and the piston rod, leading to highest durability of these wear parts. In-house tribology research and the use of latest material technology, as proven in our test facility, result in high pressure sealing elements designed for minimum wear and optimized gland performance.

Resulting benefits

- for dry-running oil-free compression

- for pressures up to 350 bar

- for longest lifetime

- low maintenance costs