BC ACTIVATE

BC ACTIVATE –

for enhanced sustainability and reliability

BC ACTIVATE is a structured assessment program to analyze, evaluate and optimize your compressor system.

Using advanced measurement and analysis techniques based on our OEM expertise, we can enhance reliability and sustainability. A thorough assessment reveals any issues such as bad actors, inefficient utilities & energy use, gas leakages, excessive vibration and more. BC ACTIVATE works with compressors of any type, age and duty; it can be applied to just an individual compressor or an entire fleet.

Reduced leakage – extended lifetime

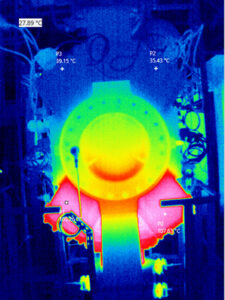

A customer reported that the lifetime of the sealing system and piston rod packing was below three months, gas leakage was high causing inefficiencies in operation, and the piston rod surface polished during operations. All these issues had to be looked at in a full system assessment to find the root causes. Experts from Burckhardt Compression went on site to analyze the situation and employed different techniques to assess and measure.

We took the time to understand the maintenance and operation routines and performed a thorough visual inspection of the compressor system. We collected data by measuring important factors such as geometry, roughness, leakage, vibration, and energy usage, while also reviewing the maintenance documentation. It is very important to understand the full history and operation mode of the system.

With the collected data, we identified possible failure root causes and eliminated them. We discovered that the high leakage was a consequence improperly selected material resulting in low adaptability and stiffness of the sealing elements. The combination of abrasive ring material and not-optimal piston rod coating were causing surface polishing, leading to inefficiencies in operation. Additionally, the sealing elements’ short lifetime was a result of poor selection of the tribological system.

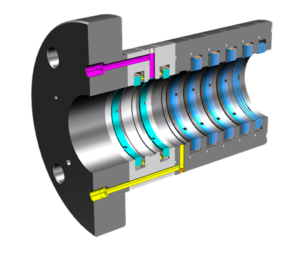

Now that we understood the causes, we were able to provide effective solutions to improve the situation. We recommended using our proprietary Persisto® 851 material for the piston and rider ring, as well as the packing elements. This material is specifically designed for reciprocating compressors . We suggested a new cylinder liner that not only provides superior sealing but also offers optimized surface finishing. This unique combination ensures minimal leakage and exceptional performance. We coated the piston rod with a specially formulated finishing that is specifically designed for dry-running operations. This coating enhances the durability and longevity of the rod, further reducing the chances of leaks and breakdowns.

The results achieved with our solutions are nothing short of extraordinary. Sealing efficiency has been increased by an impressive 10 to 15 % and the piston rings and packing lifetime has been extended from 3 to 24+ months. This means fewer disruptions to operations and significantly reduced maintenance costs.

The improved availability and reliability of the compressor system allows our customer to focus on the core business. With our solution in place, profits can be maximized.

Reliability and sustainability analyses reveal optimization potential

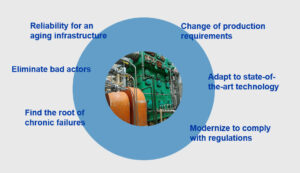

Reliability

Upgrade and optimize your compressor systems with our modernization measures. As infrastructure ages, the challenge of maintaining efficient and reliable operations becomes even greater. However, we can help you overcome this obstacle by providing a thorough assessment of your systems and implementing the most effective upgrades. Don’t let aging infrastructure hinder your operations – boost your compressor systems today for enhanced efficiency and reliability.

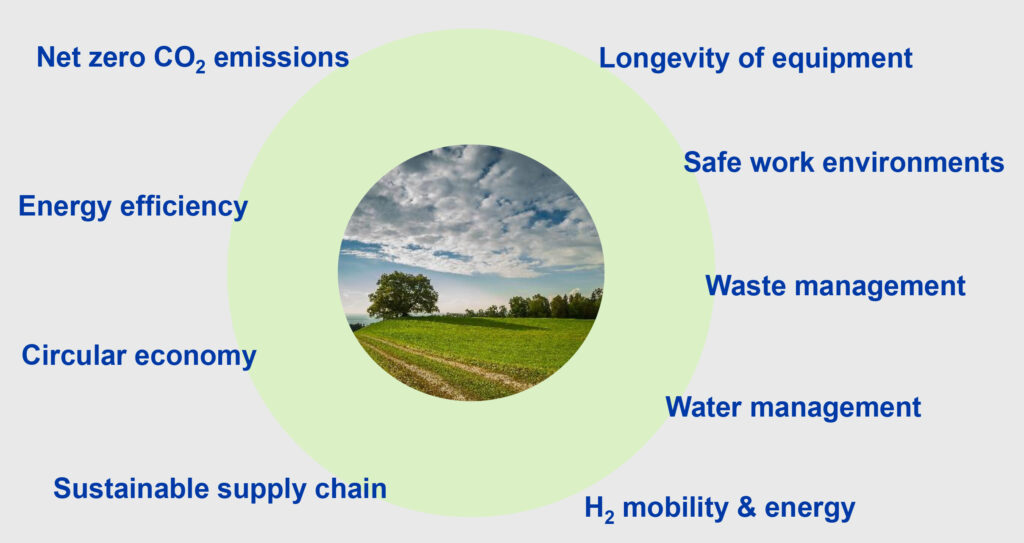

Sustainability

At our company, our primary goal is to improve the longevity and sustainability of your compressor system. We achieve this by implementing measures to minimize emissions and energy consumption. We are committed to helping you pave the way for a brighter future.

BC ACTIVATE Marine

Evaluate the state of your entire cargo handling system before an upcoming dry dock.

With BC ACTIVATE Marine, we assess your system in preparation of a dry-dock event. We rely on data provided by the customer as well as our own meticulous measurements to assess the system’s performance.

Our main objective is to identify any “bad actors” in the system, i.e., components that are not functioning optimally or are prone to failures. By collecting relevant data during our evaluations, you can better plan for the dry-dock phase and we ensure that necessary repairs or replacements are carried out effectively. Defining the scope of work for the upcoming dry-dock phase will become so much easier. This program will help us focus on the specific areas that require attention, avoiding any unnecessary repair or replacement.

Additionally, we emphasize the importance of verifying the availability of spare parts in advance. This allows us to avoid any delays or disruptions during the dry-dock phase, ensuring a smooth and efficient process.

To further streamline the dry-dock phase, we prepare all the required tools and equipment well in advance. This ensures that we have everything we need on hand, minimizing any potential downtime due to missing or unavailable tools.

At Burckhardt Compression, our goal is to make the dry-dock phase as efficient as possible. By thoroughly evaluating the cargo handling system, addressing any bad actors, collecting relevant data, and planning meticulously, we strive for a smooth and successful dry-dock process.

BC ACTIVATE

- is an action-oriented assessment providing case-specific recommendations for compressor performance optimization.

- identifies compressor performance optimization potential using quantitative analysis like measurements, simulations and OPEX calculations.

- uses ownership-oriented metrics for compressor evaluation.

- combines different measurement & analysis techniques to enhance reliability & sustainability.

Measurement techniques used for the assessment:

- Vibration measurements

- Time-domain vibration diagnostics

- Infrared thermography

- Gas leakage detection

- Process parameter reviews

- Energy optimization survey

- Finding bad actors

- pV-analysis

Emission Management Solutions

Reducing fugitive emissions to counteract climate change.

We specialize in providing advanced solutions to enhance the sealing of reciprocating compressors and tackle the issue of gas escape.

- Upgrade of existing packing cases with new sealing elements

- New packing with optimized rings, i. e. MP (multi-piece) ring

- New packing with the possibility to purge and buffer the packing

- Replacement or repair of cylinders

- Emission management panel

For any type, model or make of compressor – BC ACTIVATE will reveal its optimization potential.