Gas Transport & Storage

Gas Transport & Storage

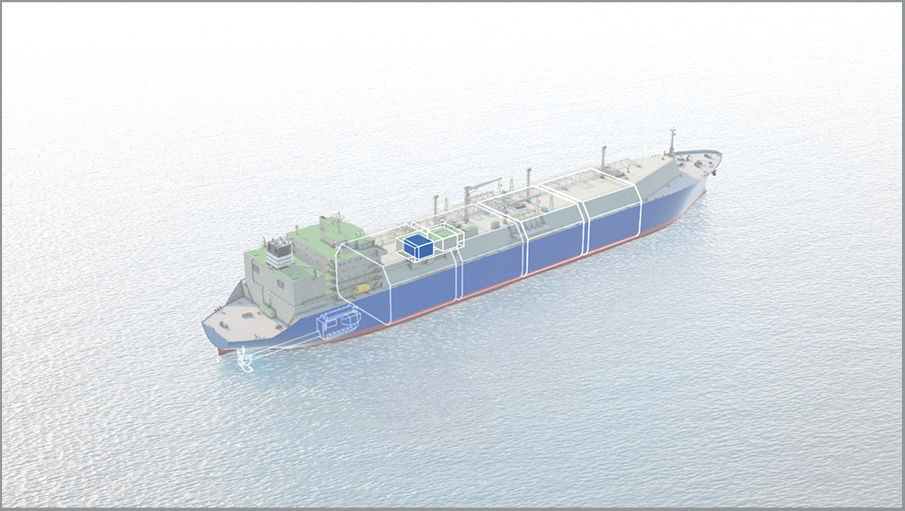

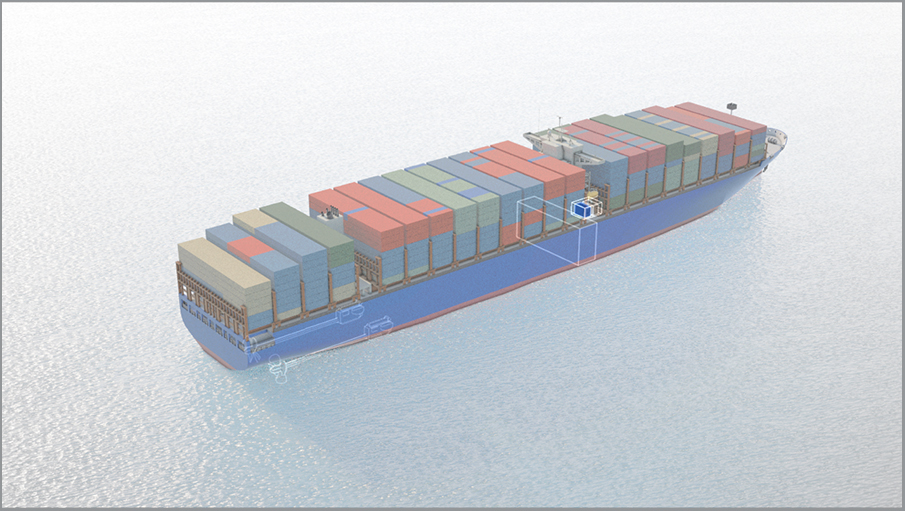

Demand for environmentally friendly natural gas as a fossil fuel will continue to increase over the long term. Because by replacing the liquid fossil fuels or diesel, gasoline and oil with natural gas the global carbon dioxide emissions would be reduced by about 25%. The development of new sources of natural gas, which is widening the gap in prices between oil- and gas-producing and importing countries, has increased international trade in natural gas, and gas transport and storage volumes are likewise growing. This is especially evident in the non-pipeline mode of gas transportation via LNG (Liquefied Natural Gas) tankers.

Massive Reduction of Volume

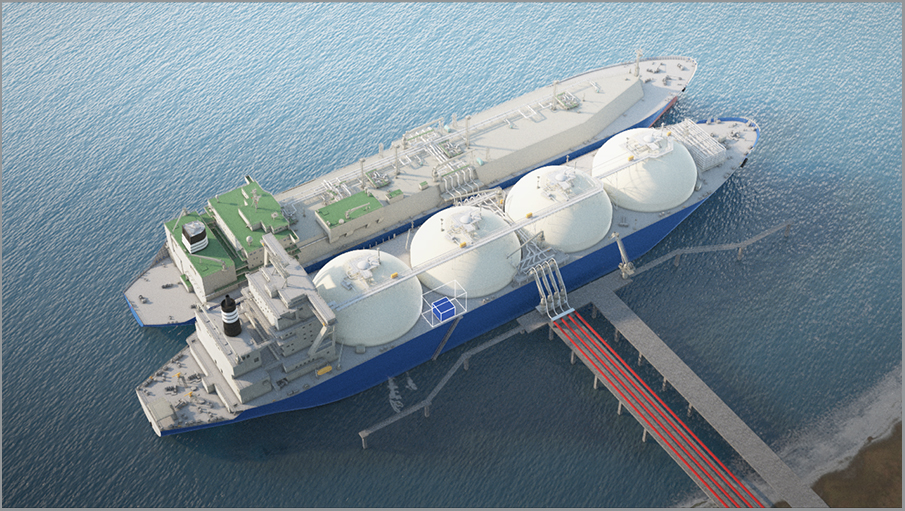

More than 40% of total natural gas transport volumes traded and transported worldwide is liquefied, which reduces transport volumes by a factor of 600. The LNG process chain consists of natural gas production, purification and liquefaction, ship loading, transportation and subsequent off-loading, storage and regasification, and, ultimately, injection into a gas distribution grid.

Burckhardt Compression offers unique, economical solutions for compressing and re-liquefying boil-off gas (BOG) from liquid gases, for gas injection systems for two- or four-stroke marine diesel engines, and for recovering or storing natural gas and other hydrocarbons at land or offshore installations.

Burckhardt Compression offers several product lines with individual, reliable and benchmark-setting reciprocating compressor solutions for a broad spectrum of applications.