Our strategic approach

We create leading compression solutions for a sustainable energy future and aspire to incorporate economic, environmental, and social apsects into our business activities and decisions. Burckhardt Compression is an industrial technology company specializing in reciprocating compression solutions for all types of gases. With a company history stretching back over 179 years and products with a useful life of more than half a century, we base our business decisions on a long-term perspective. And we approach sustainability with the same mindset: pragmatic, focused on the long-term, creating value and impact driven.

Strategic focus on eight material topics

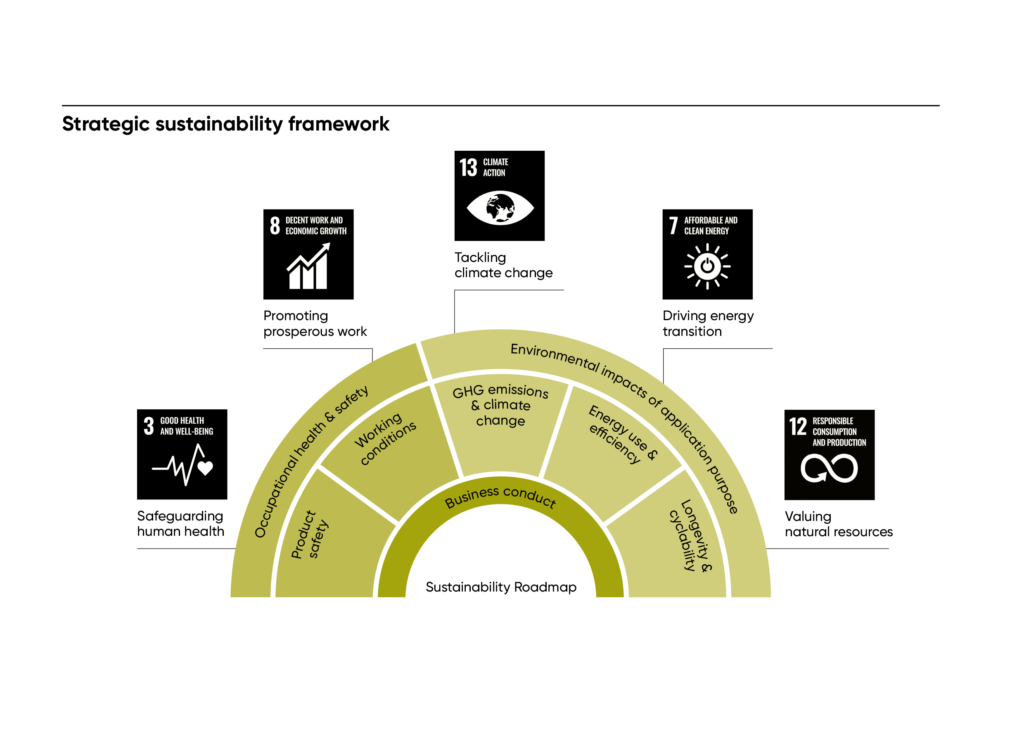

In our sustainability approach, we focus on eight material topics, which we identified analyzing our impacts on the economy, environment, and society. These eight material topics build our framework and the core of our sustainability roadmap.

Burckhardt Compression is committed to supporting the Sustainable Development Goals (SDGs) as defined by the United Nations. These SDGs address the world’s most pressing sustainability challenges and are to be achieved as part of Agenda 2030 for Sustainable Development. We have stated five sustainability ambitions, each linked to a strategic SDG and directly related to our material topics:

- Safeguarding human health (SDG 3: Good health and well-being)

- Promoting prosperous work (SDG 8: Decent work and economic growth)

- Tackling climate change (SDG 13: Climate action)

- Driving energy transition (SDG 7: Affordable and clean energy)

- Valuing natural resources (SDG 12: Responsible consumption and production)

We have also identified six additional SDG to which we can contribute.

Our senior leaders play a key role in achieving our goals, which is why sustainability is now part of the remuneration in the form of our long-term incentive plan. Our 2027 target to reduce our greenhouse gas emission intensity by 50% is one of three key performance indicators for the long-term incentive of our top management.

We developed a commitment to net-zero greenhouse gas emissions by 2035 which goes beyond our Mid-Range Plan target for 2027. We follow a 1.5°C climate aspiration in reference to the Paris Climate Agreement for Scope 1 and Scope 2 emissions. In addition, we are committed to reducing our Scope 3 emissions.

Overarching due diligence on human rights and international environmental standards

The focus on our material topics and sustainability ambitions includes an overarching due diligence approach. We acknowledge the responsibility to respect internationally recognized human rights and international environmental standards, which is also defined in our Code of Conduct. We incorporate the precautionary principle into our activities and decision-making, such as the consideration of environmental requirements in product design, the consideration of human rights in our supply chain, and the assurance of safe product operation at our customers’ sites.

Supply chain management plays a key role in this. Burckhardt Compression taps into its suppliers’ experience to continuously improve its products, because an important part of the value creation is provided by them. We source raw materials for the foundry in Shenyang, China, raw materials and semi-finished products for the manufacture of compressors in our factories, and components and other accessories to complete and maintain the compressor systems on-site. For this, we have an established global supply chain, with core suppliers for production located in the wider regional area.

Through our Code of Conduct for business partners, we set the same high standards for suppliers as we do within our company, and we also include them in our environmental and quality policy. We conduct checks on-site or when goods arrive to ensure observance of specifications and verify this by reviewing the required audit reports. We adopted a policy on conflict minerals and initiated a risk-identification process for child labor and other human rights risks. In the reporting period we also updated our supplier assessment process, including sustainability, which we will roll out in fiscal year 2023.