Emission Management Solutions

Emission Management Solutions – for enhanced sustainability

Reducing fugitive emissions to counteract climate change

Burckhardt Compression specializes in providing advanced solutions to enhance the sealing of reciprocating compressors and tackle the issue of gas escape. With our leading technology and expertise, we effectively reduce fugitive emissions from occurring at the rod. By implementing our solutions, you can significantly improve your operations, minimize environmental impact and contribute to the fight against climate change.

Addressing leakage at the rod packing

When it comes to reducing leakage at the rod packing, we offer several options to meet your specific goals. Our team of experts can help you determine the most suitable solution based on your requirements.

Improve sealing efficiency and reduce leakage

Our customer approached us when he recognized a leakage rate of more than 7 Nm3/h on his single-stage, non-lubricated process gas compressor.

We suggested an upgrade from a 3-ring to a much tighter Burckhardt 4-ring design adding one more support ring as 4th barrier, no material change.

The result was amazing, a reduction in leakage rate to 1.2 Nm3/h (in average) even after 7’600 hours of operation.

Increase sealing life and reduce leakage

A non-Burckhardt, dry running compressor compressing a gas mix of 90% H2 and 10% CH4 showed very early a high leakage rate resulting in a low lifetime of the packing. It didn’t match the customer’s regular maintenance schedule of a minimum of 4’000 hours.

We offered our proprietary MP (multi piece) rings in Persisto® 850 material, specifically designed for reciprocating compressors in addition to a newly designed packing to increase runtime.

With these changes, the customer reached a packing lifetime of minimum 8’000 hours and reduced the leakage rate significantly.

Improve safety with packing revamp

An additional buffer system was installed on a lubricated process gas compressor to avoid mixing of process gas with nitrogen. The clean process gas can be reinjected into the process, eliminating the need for flaring.

The buffer system was equipped with two leak gas connections to separate the gases properly.

It not only made the compressor tighter but also much safer for the environment and the people.

Reliable and proven solutions

At Burckhardt Compression, we have a strong foundation in OEM engineering, which allows us to develop and deliver solutions that have been proven to be technically sound. Our customers trust us to provide them with sealing solutions that not only work efficiently but also have a long-lasting impact on their operations.

Sealing system upgrade

- Existing rings and sealing elements with newest design optimally combined using the optimal materials to allow lowest leakage.

Designs and ring technologies:- MP (multi–piece) rings

- Optimized MP rings (new design)

- 4-ring system

- 6-pieced rings

- Materials:

- Persisto® 850

- Persisto® 59/8400 for wet CH4

- Persisto® 850/8400 for dry and bone dry CH4

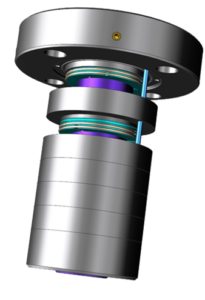

New packing

- Completely new packing solution

- Combination of newest ring designs and material technology

- Soft iron seal is creating a superior seal between the packing case and the cylinder

- O-rings between each cup will give an additional layer of protection from gas leaking between the cup faces

- Lapped sealing surfaces for all packing cups to reduce leakage between the cups

New packing with purge and buffer

- Completely new packing with the possibility to purge and buffer the packing

- Buffer connection to avoid process gas entering the distance piece

- Combination of newest ring designs and material technology

- Vent connection to transport minimal leak gas to a safe location, a collection system or to the flare

(if the connection pipes are already existing)

Engineering services complement our product offering

Our engineering services are a valuable addition to our product offerings. We go beyond providing rod packings and offer solutions to assess and optimize the cylinders on your compressors. Our goal is to ensure the highest sealing and maintainability standards.

Through our static sealing solutions, we can effectively seal your cylinders and minimize leakage. We also perform pressure and leakage testing to evaluate the state of your cylinder sealing. By utilizing a buffered actuator design and optimizing the main packing dimensions and configuration, we provide additional possibilities for achieving emission reductions.

To help you manage emissions effectively, we offer emission management panels. These panels not only prevent gas leakages around the compressor, but also control the supply of inert gas for buffering or purging. They also allow you to monitor the flow of leak gas, serving as a direct indication of the pressure packing condition.

With our comprehensive engineering services, we aim to provide holistic solutions to optimize the performance and efficiency of your compressor systems.

Burckhardt Compression is your partner helping you to reach your sustainability goals

Our commitment revolves around delivering cutting-edge Emission Management Solutions that holistically address Greenhouse Gas (GHG) and fugitive emissions. Leveraging our extensive global engineering expertise, we ensure tailored solutions for any challenge you aim to conquer.

The journey towards sustainability requires not only visionary ideas but also meticulous execution. At Burckhardt Compression, our Service Centers worldwide adhere to consistent procedures, ensuring highest quality in implementation. Our experts use the latest techniques, guaranteeing that every solution is seamlessly integrated. Central to our mission is the utilization of proprietary materials and solutions that amplify the sustainability and dependability of your compressors. This dual approach not only lowers costs but also minimizes health risks.

Take the next step on your sustainability journey with BC ACTIVATE

BC ACTIVATE is a comprehensive compressor assessment program designed to optimize the performance of compressors. By utilizing a combination of various measurement and analysis techniques along with our expertise, we enhance the reliability and sustainability of compressor operations.

This program is suitable for compressors of any type, age, and duty, whether they are individual machines or part of a larger fleet. We identify areas for improvement and implement strategies to maximize compressor efficiency.

Find out how BC ACTIVATE can benefit your operations!

For any type, model or make of compressor – our Emission Management Solutions reduce fugitive emissions.