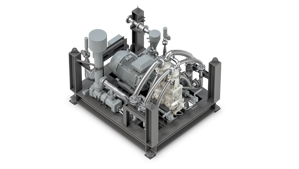

Laby® Compressors

Laby® Compressors – Contactless Labyrinth Sealing for Highest Availability

Since Burckhardt Compression first introduced the Laby® Compressor in 1935 we have been able to increase our application know-how. In close cooperation with our customers we have transferred this know-how into a second to none compressor solution with outstanding performance. Originally designed for the safe compression of ammonia, continuous improvements and further developments have made the Laby® today one of the most reliable compressor solutions for numerous applications handling complex gases:

– bone-dry gases

– humid gases

– cryogenic gases

– dirty, dust-laden, contaminated gases in fouling services

– clean gases where no pollution of the gas is allowed

– reactive, explosive, corrosive or toxic gases

All major industrial gas suppliers, global players in the polyolefin production, renowned process licensees, international partners for gas liquefaction systems and many producers of chemicals trust Burckhardt Compression and depend on the unsurpassed reliability of Laby® Compressors. Thousands of installations underscore this long success story.

Markets and Applications

Click on a market to switch, or on the red button below to continue with Laby® Compressor