Labyrinth Sealing

What’s the Secret Behind?

Labyrinth Sealing – Contactless, Oil-Free Compression

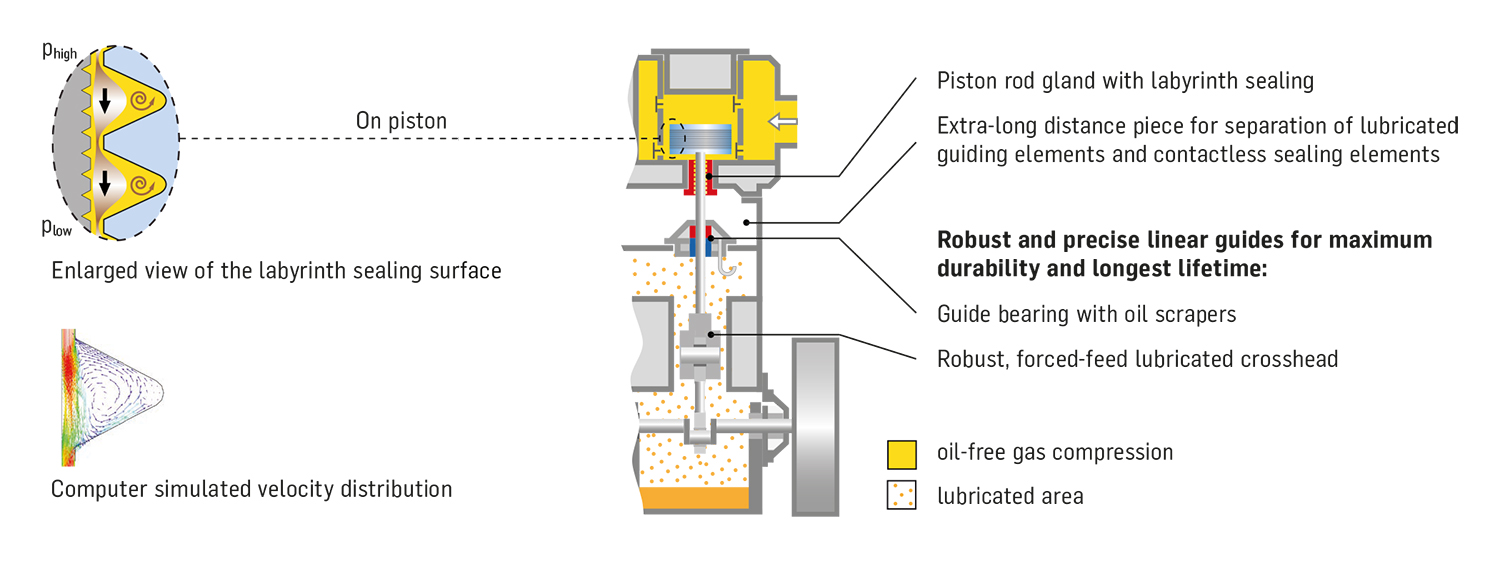

The unique technology is applied between the piston and the cylinder wall and between the piston rod gland and the piston rod. The labyrinth sealing effect is created by numerous tiny throttling points. At each of these throttling points, pressure energy is transformed into kinetic energy as a result of the flow restriction. The process continues at each throttling point/volume chamber combination along the piston and piston rod gland until the required reduction in pressure is attained. A small clearance volume is maintained between the adjoining surfaces. The low level amount of gas passing through the sealing system is recovered internally.

Separation of Sealing and Guiding Elements – Lowest Wear

The strict separation of the lubricated guiding elements in the crankgear from the contactless sealing elements of the piston and piston rod is essential for the functionality and efficiency of the compressor. The oil scraper rings, located close to the guide bearing, ensure the most efficient removal of oil from the piston rod. Lubricating oil is prevented from entering the compression room.

Customer Benefits

- No permanent mechanical friction in the compression area – no wear

- Minimum quantity of wear parts

- Longest MTBO

- Lowest maintenance costs

- No contamination of highly pure gases with oil or abrasives from piston rings or rider rings

- No loss of valuable product

- Lowest operating costs

- Safest compressor for oxygen service

- No friction – no hot spots in the cylinder

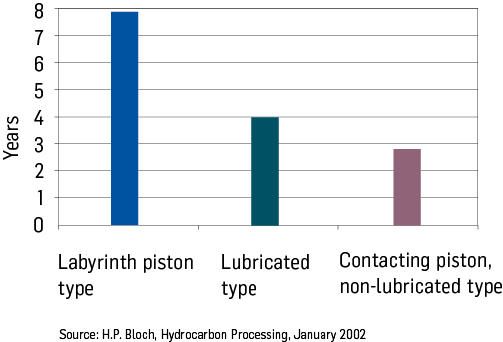

Independent Research Has Revealed

Up to 2.5 times higher reliability through reduced MTBF (mean-time between failure) of reciprocating compressors