Solar energy: with the power of the sun

The solar panel market is growing fast, driven by the energy transition. Our Hyper Compressors are used in the production of ethylene vinyl acetate (EVA) co-polymer, needed for manufacturing solar panels.

What is ethylene-vinyl acetate?

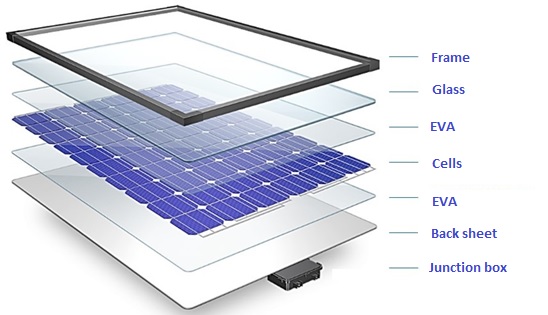

Ethylene-vinyl acetate (EVA) is used to encapsulate the photovoltaic cells inside solar panels. The encapsulant material must be long-lasting and tolerant to extreme temperatures and humidity, as it plays an important role in the long-term performance by preventing moisture and dirt ingress. The lamination of either side of the cells provides some shock absorption and helps protect the cells and interconnecting wires from vibrations and sudden impact form hail stones and other objects.

A high-quality film with a high degree of what is known as “cross-linking” can be the difference between a long life or a panel failure due to water ingress. During manufacture the cells are first encapsulated with the encapsulant film before being assembled within the glass and back sheet.

EVA/LDPE Producer, China:

“The rapid development of the domestic photovoltaic industry greatly stimulated the demand for EVA, so we decided to build more EVA plants. We selected Hyper Compressors from Burckhardt Compression. We believe that we made the right decision to choose Burckhardt Compression in a previous project, and we really appreciated the good performance of the compressors and the sound service. Therefore, we decided to go with Burckhardt Compression again.

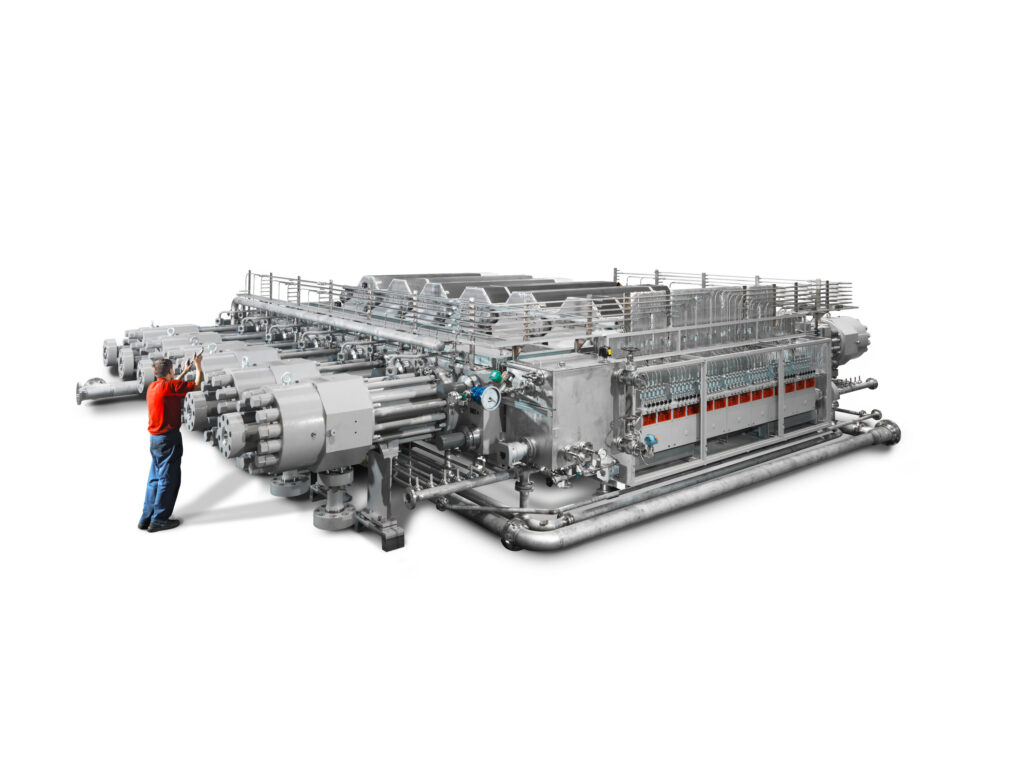

Hyper Compressor for EVA and LDPE

The production of EVA requires a high-pressure process with an autoclave or tubular reactor, which is only possible with Hyper Compressors reaching pressures between 2’400 and 3’500 bar. Burckhardt Compression is the clear leader in this application.

In fiscal year 2022 Burckhardt Compression received a record number of orders, mainly due to the growing demand for solar panel production in China and South Korea. In addition, Burckhardt Compression received a large number of orders for piston-ring compressors used in the production of polysilicon, which is a core component of the solar cells themselves.

Polysilicon

Solar cells made of polysilicon collect the sunlight and convert it into electricity. To produce polysilicon, hydrogen and hydrogen-mix compressors are utiilzed, mostly in “vent recovery” services where the compressor must handle contaminated gases. Non-lubricated machines are required. In fiscal year 2022, Burckhardt Compression, via its Chinese subsidiary Shenyang Yuanda, received a record number of order for this application.

A Hpyer Compressor on its way to Lianyungang Seaport in China

K10 Hyper Compressor

- Length: 12 meters

- Width: 7 meters

- Height: 2.5 meters

- Weight: 280 tons

Project Director, South Korea:

“Thanks to the great cooperation with Burckardt Compression for mroe than a decade, our company chose again the reliable Hyper and Booster/Primary compressors from Burckhardt Compression for the most recent project, which will produce EVA for solar cells, contributing to the energy transition.”

Polysilicon Producer, China:

“Our company responds to the national goal of ‘carbon peak and carbon neutrality’ and ‘the Belt and Road’ initiative, to collaborate in the supply chain, and to take innovation and development with Shenyang Yuanda Compressor Co., Ltd. to a next level. We signed contracts for hydrogen compressors and are willing to discuss long-term cooperation and to promote win-win for both enterprises.”