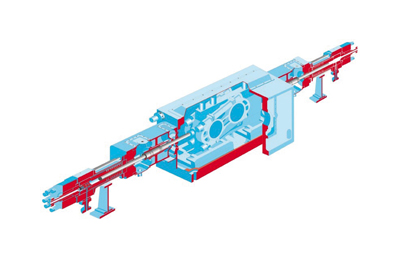

Hyper Compressors

Hyper Compressors – Customer’s First Choice since 1951

The Hyper Compressor is a high-pressure reciprocating compressor for low density polyethylene plants and compress ethylene with discharge pressure up to 3’500 bara (50’000 psia). Burckhardt Compression has an outstanding experience of over 55 years in manufacturing Hyper Compressors. They excel with long lifetime and high safety requirements thanks to its unique design features and Burckhardt Compression’s worldwide one-stop service.

The once world’s most powerful compressor, driven by a 27’500 kW (36’900 HP) electric motor and compressing 160 tons of ethylene per hour to a discharge pressure up to 3’100 bara (45’000 psia), was built by Burckhardt Compression in 2007. Since then, Burckhardt Compression was able to deliver many more projects in this performance range.

Three Different Frame Sizes

To cover the increasing demand for higher capacities in today’s LDPE plants, three different frame sizes with progressively larger cylinder diameters, longer strokes and higher admissible frame power are available. This minimizes the number of cylinders in operation for maximum availability of the client’s plant.

| Frame Type | H | F | K |

| Maximum number of cylinders | 8 | 10 | 14 |

| Maximum gas load (kN) | 1’100 | 2’000 | 3’500 |

| Maximum rod load (kN) | 900 | 1’750 | 2’600 |

| Maximum stroke (mm) | 360 | 410 | 450 |

| Maximum speed (rpm) | 257 | 231 | 215 |

| Maximum frame power (kW) | 8’000 | 20’000 | 38’000 |

Significantly Lower Speed

Hyper Compressors from Burckhardt Compression are normally operating at a low nominal speed. The low nominal speed ensures minimum wear and tear of moving parts and therefore maximizes reliability and availability.

| Frame Type | H | F | K |

| Maximum number of cylinders | 8 | 10 | 14 |

| Maximum gas load (kN) | 1’100 | 2’000 | 3’500 |

| Maximum rod load (kN) | 900 | 1’750 | 2’600 |

| Maximum stroke (mm) | 360 | 410 | 450 |

| Nominal speed (rpm) | 200 | 200 | 200 |

| Maximum speed (rpm) | 257 | 231 | 215 |

| Maximum frame power (kW) | 8’000 | 20’000 | 38’000 |