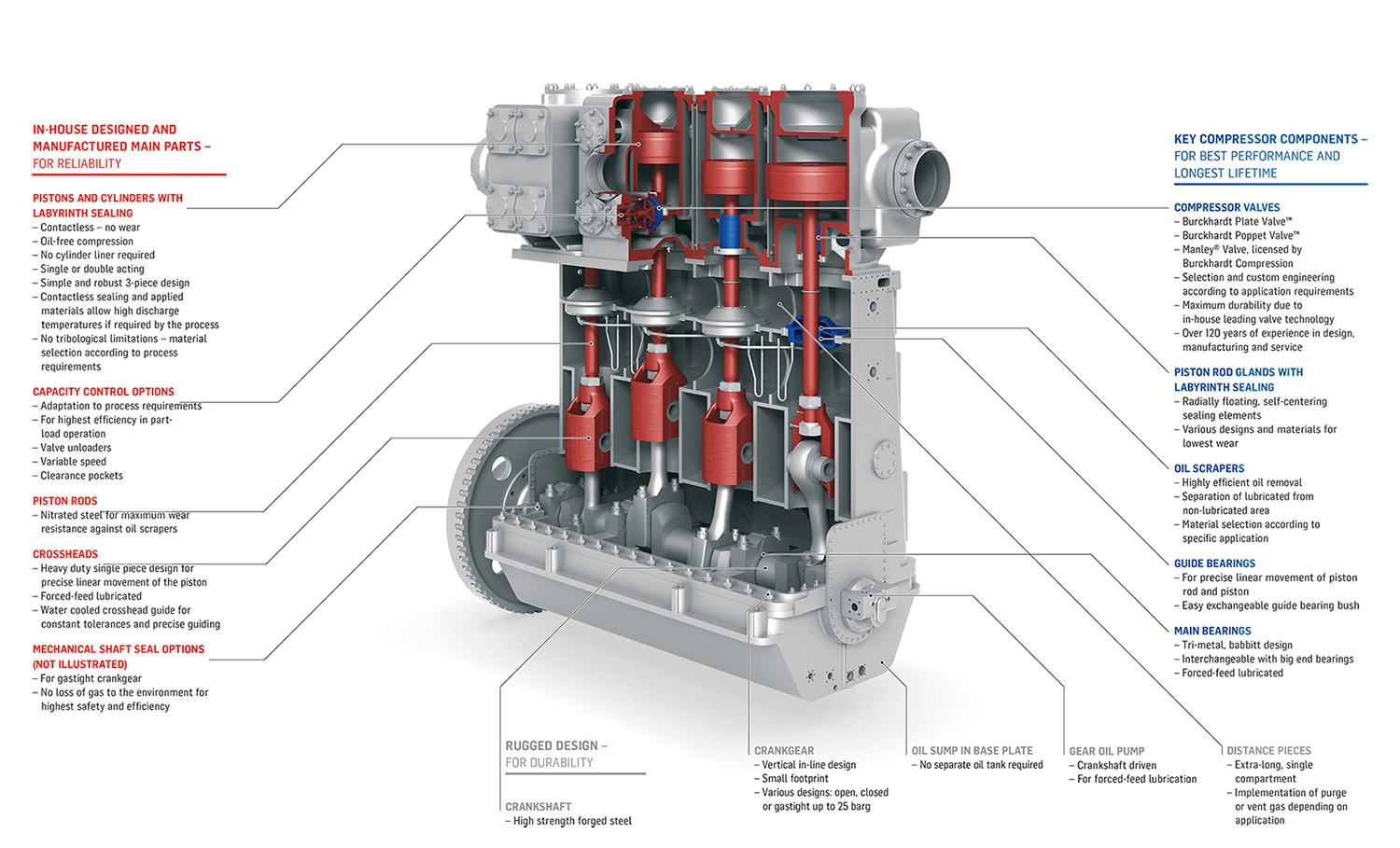

Design Features

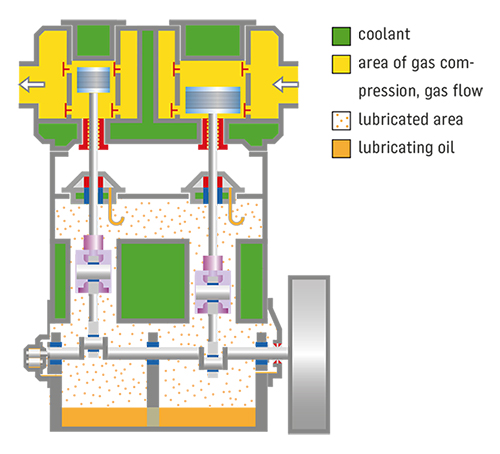

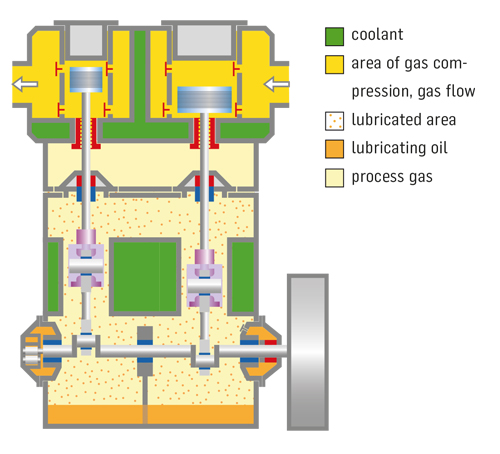

Industrial Gas – Highest Purity for Non-Toxic Gases

Main features

- Crankgear under atmospheric pressure

- Open distance piece (purging as option)

Customer benefits

- Delivery of pure gas

- Highest operational safety

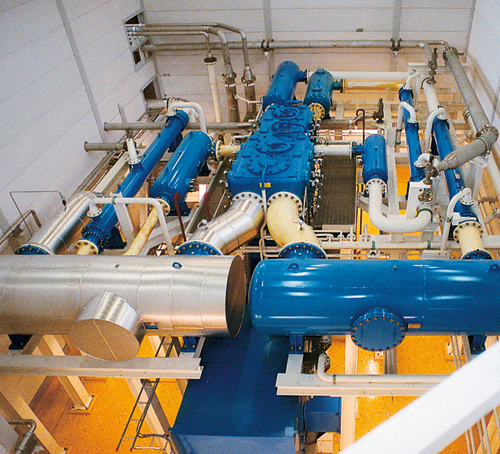

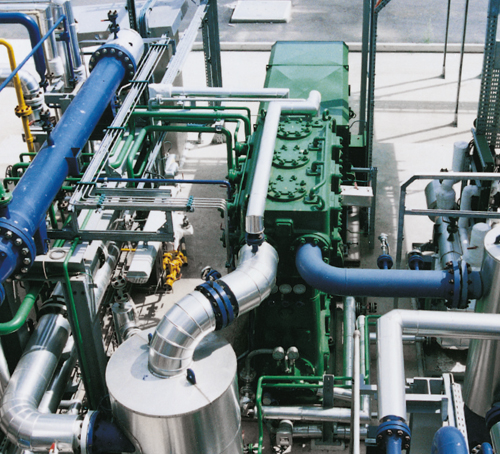

Oxygen for steel production at an air separation unit in Sweden

Gas: O2

Laby® type: 4D300

Suction volume: 5’340 m3/h / 9’072 scfm

Suction temperature: 10 °C / 50 °F

Suction pressure: 1.2 bar a / 17.4 psi a

Discharge pressure: 46 bar a / 667 psi a

Shaft power: 1’030 kW / 1’380 hp

Speed: 420 rpm

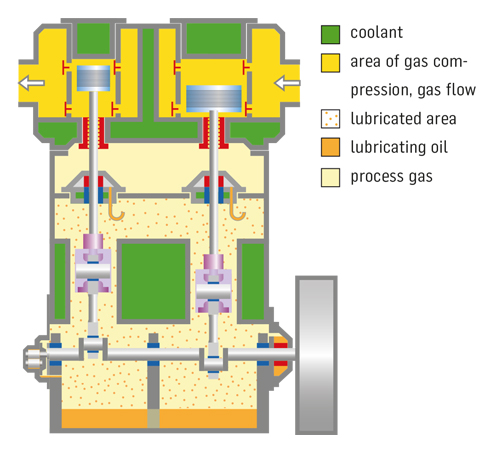

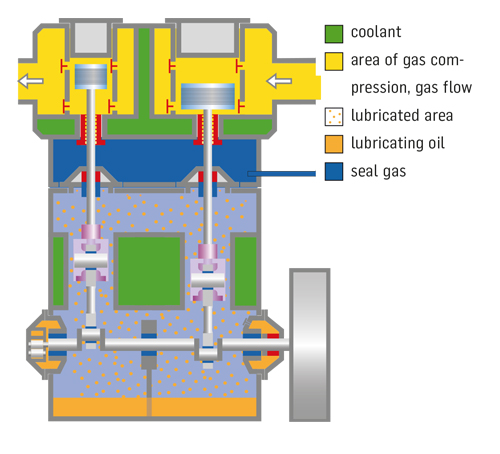

Industrial Gas – Highest Safety for Toxic, Corrosive and Explosive Gases

Main features

- Gas-tight crankgear

- Crankgear under suction pressure

- Mechanical crankshaft seal

- Closed distance piece

Customer benefit

- Highest operational safety

Carbon monoxide for acetic acid production at a petrochemical plant in Malaysia

Gas: CO mix

Laby® type: 4D250

Suction volume: 2’620 m3/h / 4’451 scfm

Suction temperature: 35 °C / 95 °F

Suction pressure: 1.5 bar a / 22 psi a

Discharge pressure: 26 bar a / 577 psi a

Shaft power: 575 kW / 770 hp

Speed: 490 rpm

Petro-/Chemical Industry – Highest Reliability for Contaminated Gases

Main features

- Gas-tight crankgear

- Mechanical crankshaft seal

- Closed distance piece

- Seal gas

Customer benefits

- Highest reliability

- Highest efficiency

- Highest operational safety

Polypropylene, polethylene and EO/EG production at a PCI plant in Belgium

Gas: C3H6

Laby® type: 3K160

Suction volume: 725 m3/h / 1’232 scfm

Suction temperature: 30 °C / 86 °F

Suction pressure: 6.8 bar a / 98.6 psi a

Discharge pressure: 24.9 bar a / 361.1 psi a

Shaft power: 228 kW / 305 hp

Speed: 494 rpm

Gas Transport & Storage – Highest Flexibility for LNG, LPG, LEG, CnHm BOG

Main features

- Gas-tight crankgear

- Mechanical crankshaft seal

- Closed distance piece

Customer benefits

- Highest flexibility

- Highest efficiency

- Highest operational safety

Boil-off gas handling at an LNG terminal in Spain

Gas: CH4 mix

Laby® type: 2D250

Suction volume: 3’015 m3/h / 5’122 scfm

Suction temperature: -150 °C / -238 °F

Suction pressure: 1.17 bar a / 17 psi a

Discharge pressure: 10.3 bar a / 149 psia

Shaft power: 520 kW / 697 hp

Speed: 495 rpm