Intermediate Storage

High-Pressure Compressors for LNG BOG Management – Intermediate LNG BOG Storage on Bunker Ships

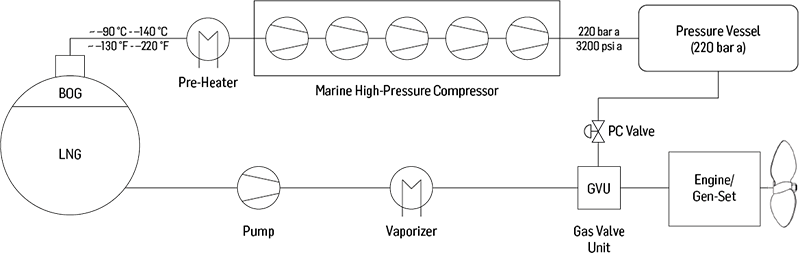

While refueling LNG-powered ships, the vapor return boil-off gas (BOG) must be handled to maintain LNG tank’s pressure. The preferred and most economical way of managing the BOG is to compress and store it in high-pressure vessels located on the bunker ship, for use when it is needed as propulsion fuel.

Burckhardt Compression offers a variety of compressor solutions for BOG handling that have been specifically designed for marine applications. Our Marine High-Pressure Compressors can compress the

BOG for intermediate storage.

Customer Benefits

- Low investment cost for Marine High-Pressure

Compressor system required (attractive CAPEX) - Gas-tight crankcase for greater safety and zero gas loss

- Possibility of installing redundant BOG-handling

compressors - Low power consumption leads to minimized

operational costs (OPEX) - Small footprint and minimum weight

- Low system complexity for easy integration

- Ship’s crew can perform onboard maintenance

- Full range of after-sales services available

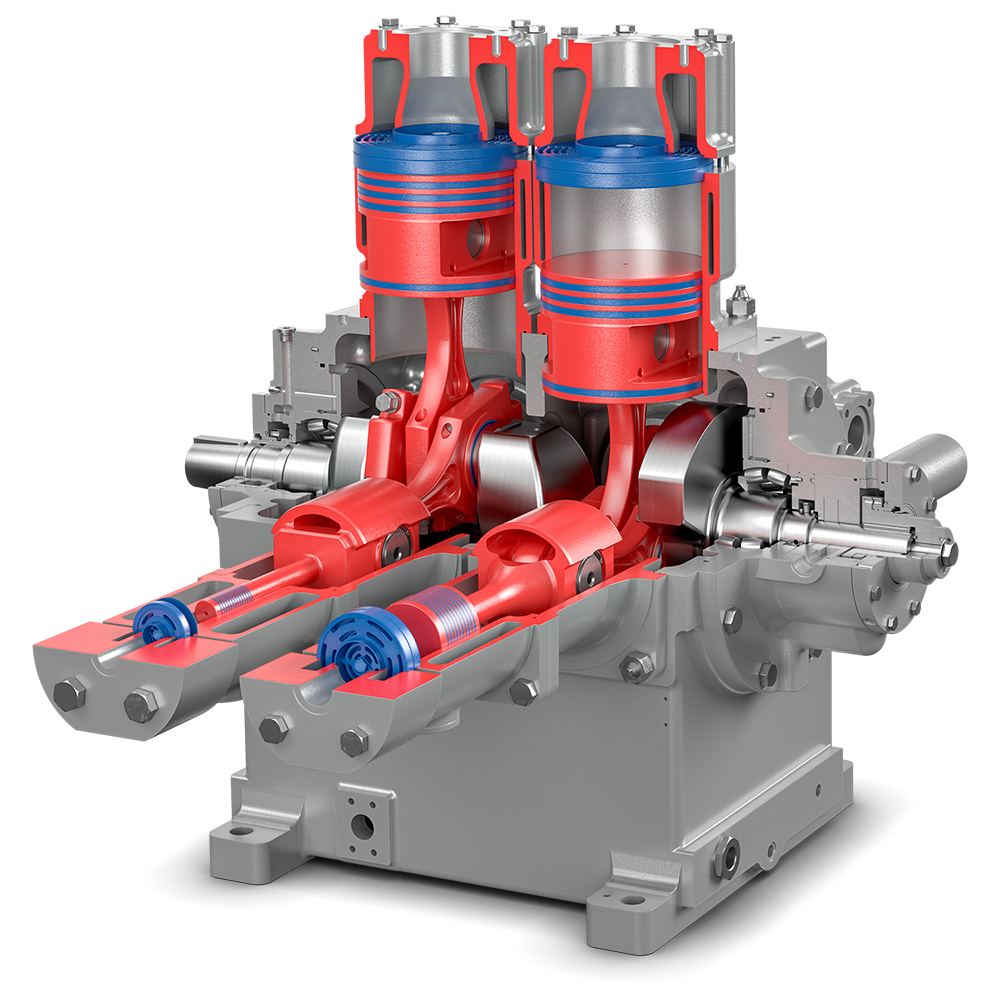

Design Features

- Robust marine design

- Directly driven by an electric motor

- Installed on anti-vibration mounts

- Water-cooled cylinders and gas coolers

- Integrated crankshaft-driven lube oil system

- Compliant with IMO, IGF and IGC codes

- Designed according to marine standards

Process Layout

Technical Data

| Type | Max. Speed rpm |

Rated Power kW / hp |

Mass Flow* kg/h / lbs/h |

Width mm / in |

Height mm / in |

Length mm / in |

Weight kg / lbs |

| MHP-C-220 | 1’180 | 350 / 470 | 900 / 1’985 | 3’250 / 128 | 3’150 / 124 | 6’700 / 264 | 24’700 / 54’465 |

*Gas composition: CH4/N2-85/15%. Suction pressure: 1.03 – 1.1 bar a (14.9 – 16 psi a). Gas suction temperature (pre-heated): –40 °C (–40 °F)