September 12, 2023 | Compressor package, Success Story, North America, Non-Burckhardt, Gas Gathering & Processing

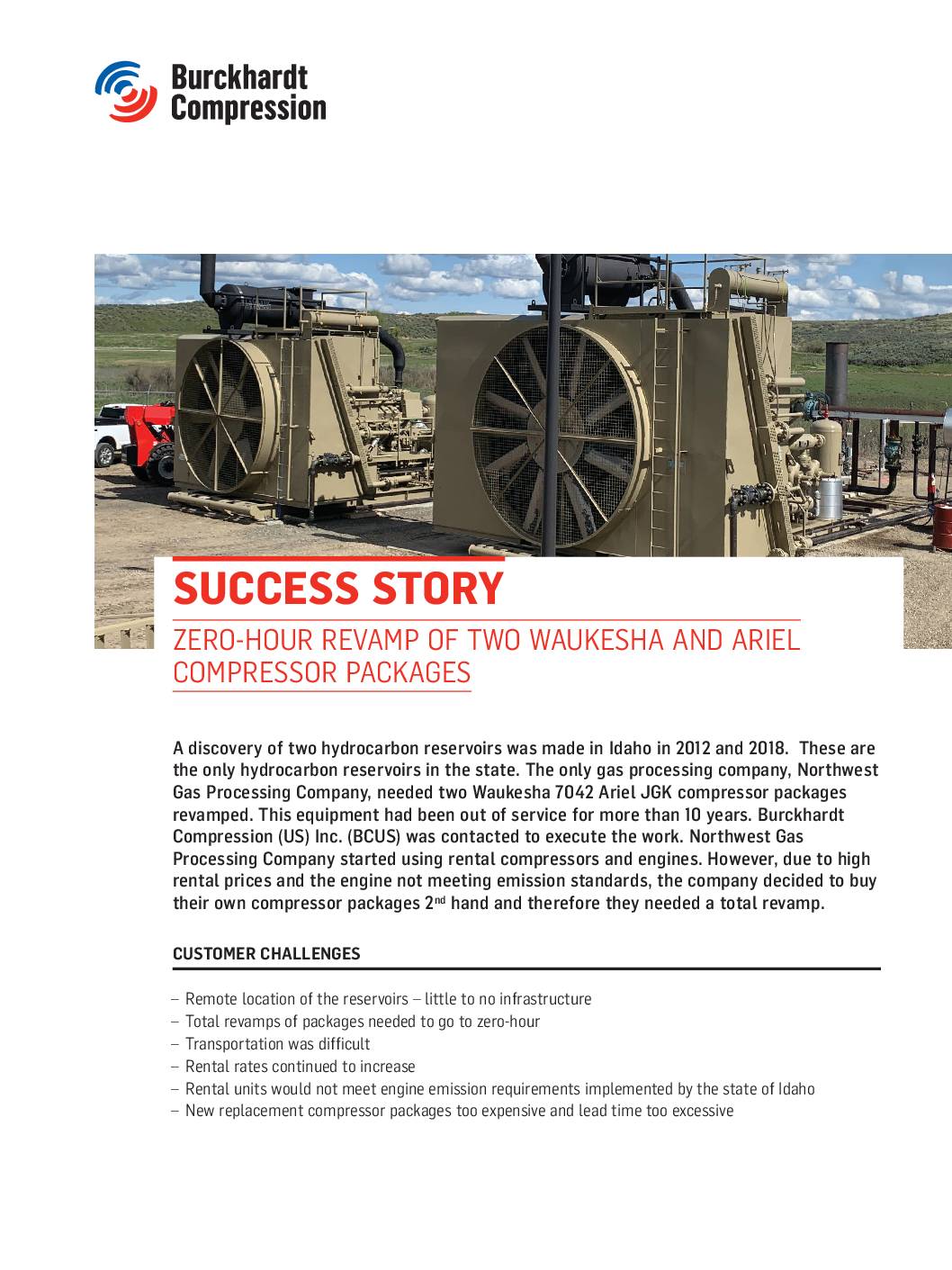

Zero-hour revamp of two Waukesha and Ariel compressor packages

A discovery of two hydrocarbon reservoirs was made in Idaho in 2012 and 2018. These are the only hydrocarbon reservoirs in the state. The only gas processing company, Northwest Gas Processing Company, needed two Waukesha 7042 Ariel JGK compressor packages revamped.

This equipment had been out of service for 10+ years. Burckhardt Compression (US) Inc. (BCUS) was contacted to execute the work. Northwest Gas Processing Company started using rental compressors and engines. However, due to high rental prices and the engine not meeting emission standards, the company decided to buy their own compressor packages 2nd hand and therefore they needed a total revamp.

Northwest Gas Processing Company says:

“Burckhardt Compression exceeded expectations and the team was awesome in all stages of the project, from submission of the quotation to commissioning & start-up, assisted operation and final delivery of the compressors under the projected conditions. During all these stages, the partnership and commitment between Burckhardt Compression and Northwest Gas Processing Company were paramount to the success of this project.”

Customer Challenges:

- Remote location of the reservoirs – little to no infrastructure

- Total revamps of packages needed to go to zero-hours

- Transportation was difficult

- Rental rates continued to increase

- Rental units would not meet engine emission requirements implemented by the state of Idaho

- New replacement compressor packages too expensive and lead time too excessive

| Machine data | |||

| Compressor Type | Arial JGK | Gas | Natural gas |

| Engine Type | Waukesha 7042 | Power | 1,480 BHP |

Burckhardt Compression Solution:

- Waukesha engines rebuilt with EICS (Engine Ignition Control System) kits installed, back to zero-hour

- BCUS as single source, from setting up cranes and trucking to totally revamping the engine and compressor packages

- Modifications to the engine to meet the emission requirements

- Installation and start-up services at the customer location in Idaho

- Spare parts for regular maintenance intervals and future minor repairs

- Zero-hour overhaul for compressor frames and cylinders

- Upgraded all skid components, control panels, and lube systems

Customer Benefits:

- BCUS was chosen for their reputation of providing quality workmanship and the experience from the field to the office

- BCUS could meet the budget and tight time frame for the revamp

- Remoteness of locations isn’t a challenge having 10 service centers in the US

- Access to best-quality OEM parts

- One-stop solution for the customer, one contact

- Increased reliability with units being at zero-hour and meeting the state’s stringent emission standards

- Highest availability of equipment provided with revamp