WinGD X-DF Engines

Compressor Solutions for WinGD X-DF Fuel Gas Injection

Burckhardt Compression offers a variety of compressor solutions for fuel gas compression that have been specifically designed for marine applications. Our X-DF fuel gas compressor systems are designed for BOG management on LNG carriers equipped with WinGD X-DF two-stroke engines.

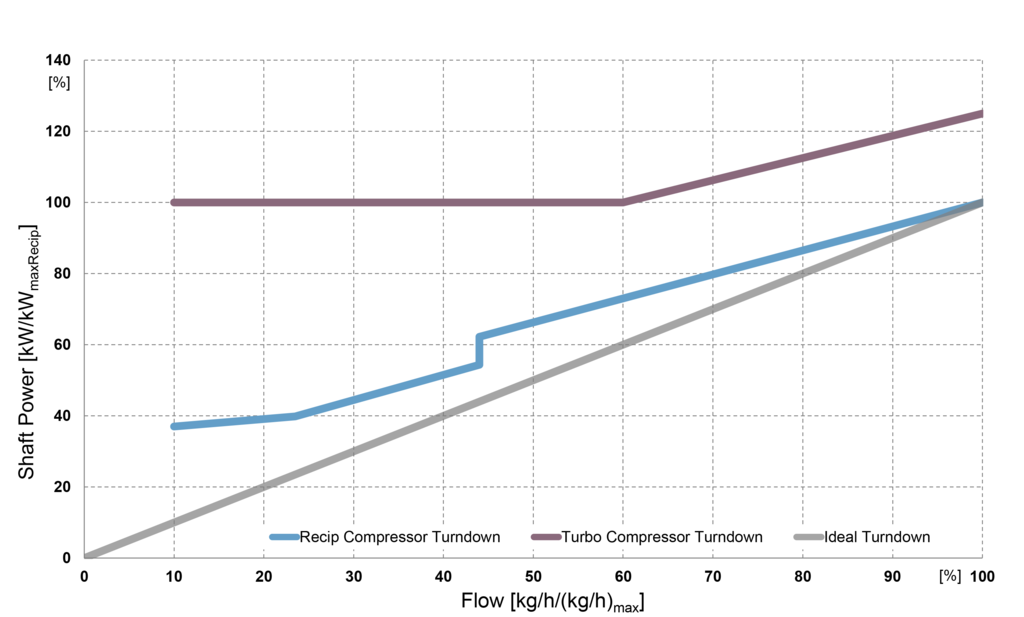

The well-proven Laby® Compressors offer the most power-efficient solution for fuel gas compression and support the optimization of the ship’s operational costs (OPEX). The oil-free compressor system can supply gen-sets, the propulsion engine and the reliquefaction system. In addition, it can be operated in parallel to the pump vaporizer unit.

Customer Benefits

- Low power consumption leads to minimized

operational costs (OPEX) - Gas-tight crankcase for greater safety and zero gas loss

- Oil-free compression to prevent oil contamination

of LNG - Low maintenance costs due to labyrinth sealing

technology - Robust process control without surge and choke

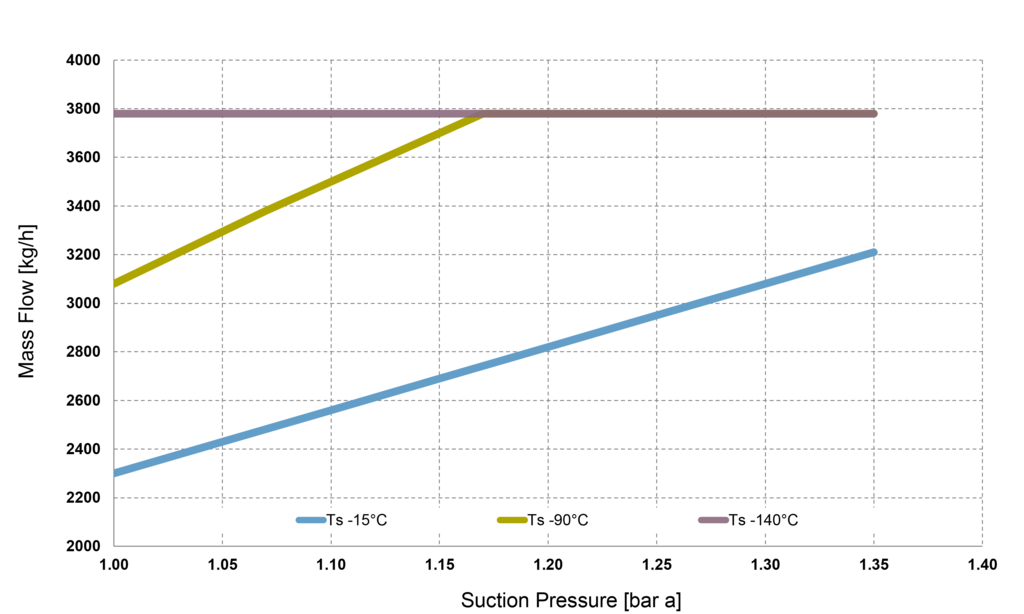

limits - Insensitivity to gas and operation conditions

- Ship’s crew can perform onboard maintenance

- Full range of after-sales services available

Design Features

- Contactless oil-free gas compression

- Cryogenic operation without BOG pre-warming

- Unique wear-free labyrinth piston sealing technology

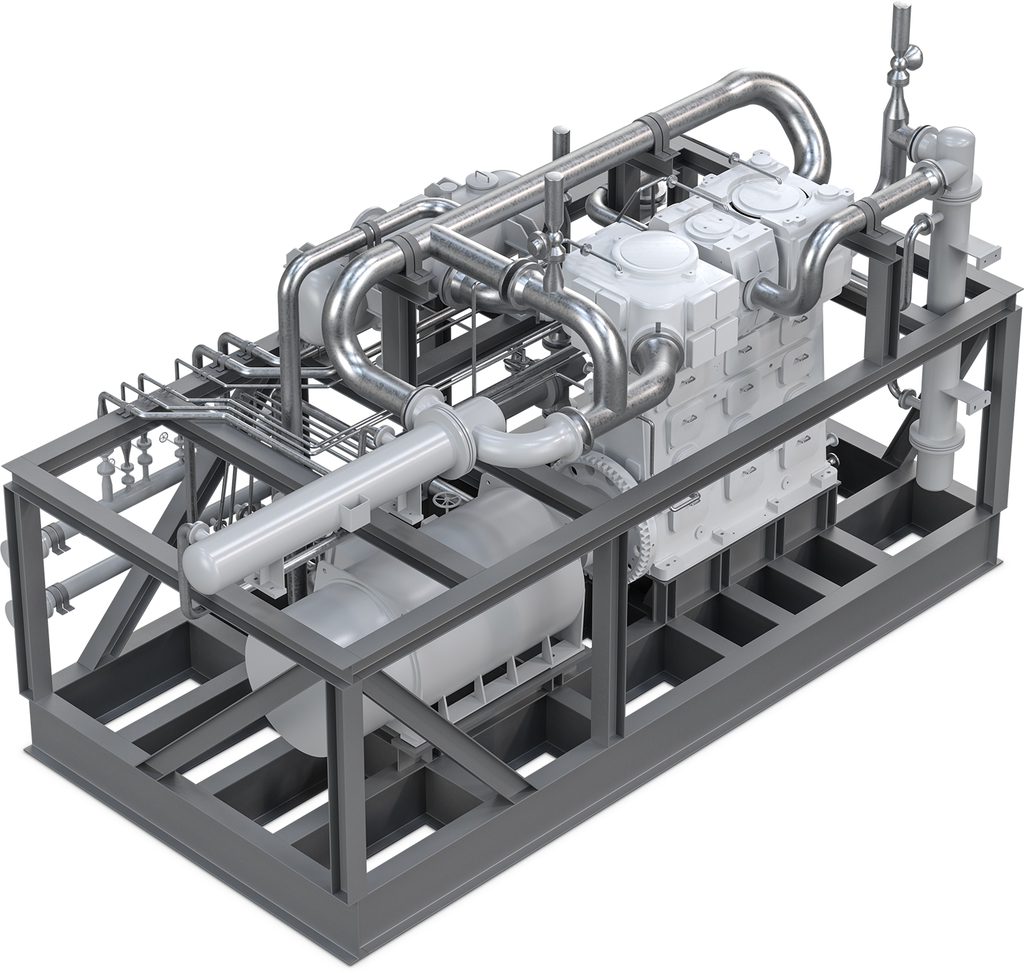

- Minimized vibrations for improved integration in marine applications

- Easy installation thanks to compact design

- Minimized quantity of wear parts

- Compliant with IMO, IGF and IGC codes

- Designed according to marine standards

Technical Data

3DL200 X-DF3’750 / 8’270590 / 7905’050 / 2004’770 / 1908’550 / 34052’000 / 114’640

| Type | Max. Mass Flow kg/h* / lbs/h* |

Rated Power kW / hp |

Width mm / in |

Height mm / in |

Length mm / in |

Weight kg / lbs |