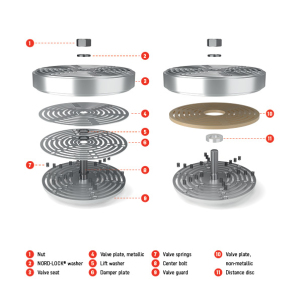

Burckhardt Plate Valve™

The Burckhardt Plate Valve™ is of proven design, and has been continually optimized over the years. Special care has been given to improve the robustness and longevity of the valve plate, damper plate and the springs under challenging operating conditions.

Main advantages are the following:Frictionless guided metallic and non-metallic valve plates for minimum wear and longest lifetime

- Up to 20 revisions of valve seat achievable, therefore very low life cycle costs

- Springs are fixed in the guard to achieve almost no spring wear

- Unequaled valve plate lifetime through careful material selection and special heat treatment. High grade X5 stainless steel is chosen as the standard material for metallic plate valves

- Lowest possible leakage rates thanks to a premium surface refinement

- 100% quality control: Every single metallic valve plate is leakage tested with a proprietary procedure

With non-metallic plates the following additional advantages apply:

- Higher ductility results in better impact properties

- More resistance to damage from liquids and debris

- Reduced wear on seat and guard during normal operation

- Greatly reduced secondary damage to other cylinder components in case of failure

Technical Details |

|

| Compressor speed | max. 1’800 rpm |

| Pressure difference | max. 200 bar / 2’900 psi |

| Temperature range | from –200 to +250 °C / –328 to +482 °F |

| Diameter dimensions | min. 68 mm / 2.68 in, max. 383 mm / 15.08 in |

Material

The valve body parts are made of standard material X12 stainless steel (AISI 416). Other proprietary materials are available on request.

- Premium grade X5 stainless steel (AISI 630)

- Hastelloy C276 for very corrosive environment

- High performance thermoplastic polymers (e.g. PEEK and polyimide with appropriate fillers)