Rings

Rings for Optimal Sealing capabilities

Optimal designs and materials for best performance

Rings, whether they be piston, packing or oil wiper rings, are a critical part of every sealing solution. A good sealing solution can contribute to improved efficiency, lower gas leakage and in the case of oil wipers, increase packing life and reduce oil wastage.

Burckhardt Compression, as a market leader in reciprocating compressors with a focus on optimal service solutions, offers standard rings as well as in-house designed, specialty rings that are tailored to reciprocating compressors and specific, demanding applications. Design paired with our Persisto® materials offer optimal lifetime and sealing capabilities.

Responding to your needs and specifications, we offer the optimal sealing solution including the optimal combination of rings and materials.

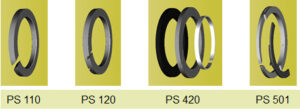

Premium Rings

Our portfolio of standard rings is complemented by premium rings for the most demanding applications such as dry-running, high-pressure hydrogen, oxygen and high-pressure methane applications.

The RS 320 multi-piece sealing ring is a novelty and exclusively designed by Burckhardt Compression. It is a robust sealing element for all gas types and conditions and extends the lifetime of your sealing solution. It can be used in dry-running as well as lubricated systems.

The PJ Piston Ring is a sealing ring suitable for high loads in all gas applications. The axially thicker part allows the use of a pressure relief groove. The joint lock can be manufactured in a stronger material than the sealing ring. It can be used as replacement for all twin-ring designs.

The RB 220 Pressure Breaker trisemic ring uniquely suitable for high differential pressures and can be used in confined spaces. It is designed for high-load dry-running and lubricated systems and all gas types.

The LW 400 oil wiper element is equipped with Burckhardt Compression’s unique Razor BladeTM technology. It is a metallic wiper ring accommodated in a non-metallic retainer for lower surface pressure compared to pure metallic versions.

We know how important the immediate access to rings is for you and your operations. Therefore, we maintain a large stock of rings and semi-manufactured materials. Additional ring types in different designs and cuts for any reciprocating compressor brand and type are available.

Call your Burckhardt Compression representative today for more information.

Call your Burckhardt Compression representative today for more information.

If you want to get more insights into how important rings, the material and the whole sealing solution are for your compressor, watch our TechXchange webinar about a zero-leakage solution.

Register here for all future TechXchange webinars to keep up to date on compressor technology.