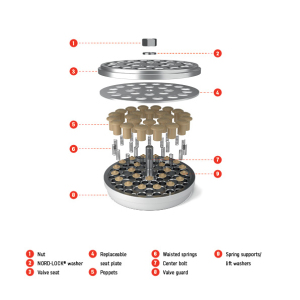

Burckhardt Poppet Valve™

The Burckhardt Poppet Valve™ is a smart choice to reduce your operating costs. It performs excellently in demanding applications with gases containing oil and particles as well for clean gases like oxygen. The optimized flow area results in less pressure drop and increased efficiency. Furthermore, the design allows for easy maintenance and offers significant advantages as follows:

Maintenance

- Valve service without special tools, reconditioning can be done on the spot

- No need for specially trained people to perform valve service

- Re-profiling of valve seat not required thanks to the replaceable seat plate

Performance

- Outstanding performance with contaminated gases, less oil stiction

- Insensitive to different thermal expansion and humidity in the gas

- Less clogging than plate valves for dirty or wet gases

- Improved aerodynamic flow path leads to lower pressure drop and higher efficiency

Safety

- Lower noise emissions and reduced vibrations achievable

- Less sensitive to variable operating conditions

- Minimized risk of secondary damage to the compressor parts in case of a failure

- The metallic springs are protected from gas stream by the non-metallic poppet body

Technical Details |

|

| Compressor speed | max. 1’000 rpm |

| Pressure difference | max. 170 bar / 2’466 psi |

| Temperature range | from –200 to +220 °C / –328 to +428 °F |

| Diameter dimensions | min. 40 mm / 1.57 in, max. 383 mm / 15.08 in |

Material

The valve body parts are made of standard material X12 stainless steel (AISI 416). Other proprietary materials are available on request.

- High performance thermoplastic polymers (e.g. PEEK and polyamide with appropriate fillers)

- Filled PTFE for cryogenic applications and for compressing highly aggressive gases